High-adsorption carbon-plastic composite material manufacturing technology

A composite material with high adsorption technology, applied in the field of carbon-plastic composite materials, it can solve the problems of application limitation, poisoning, lack of adsorption or decomposition of formaldehyde, etc. The effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

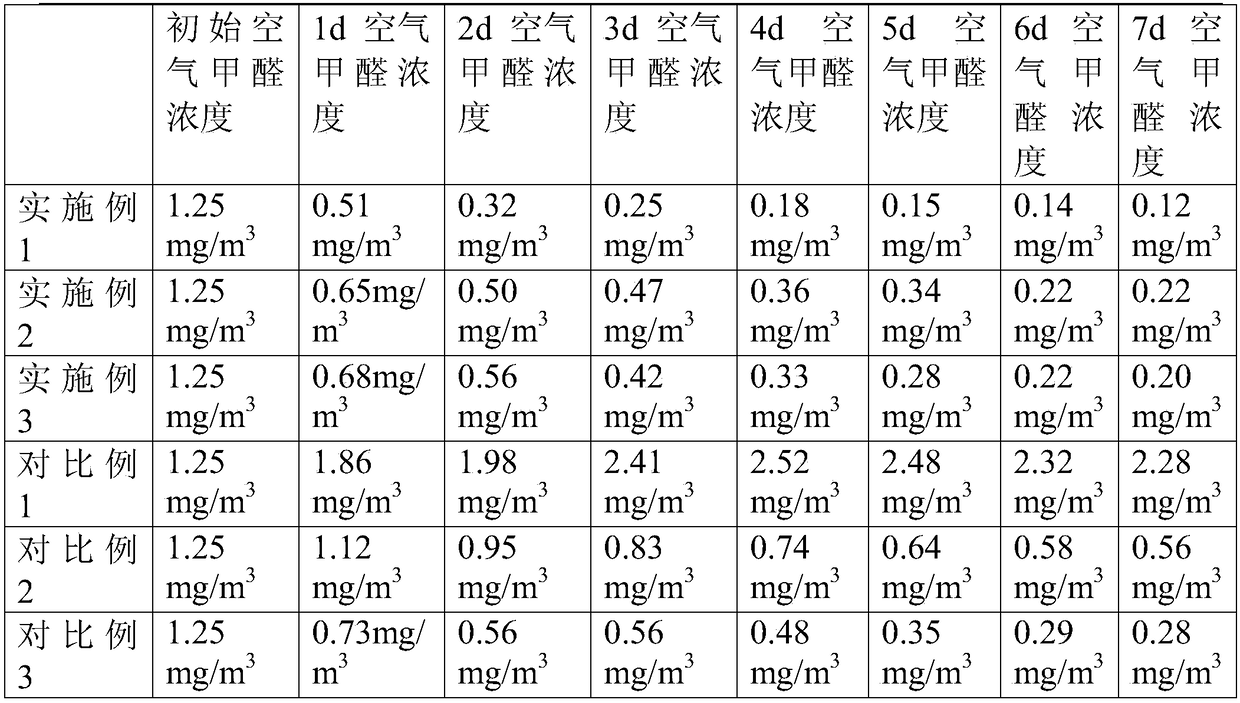

Examples

Embodiment 1

[0021] The manufacturing process of a kind of highly absorbing carbon-plastic composite material disclosed in embodiment 1 comprises the following preparation steps:

[0022] 1) According to the number of parts by mass, take 60 parts of bamboo charcoal particles with a particle size of 60 mesh, 2 parts of nano-titanium dioxide, and 1 part of a single-layer graphene oxide aqueous phase dispersion, stir at room temperature for 120 min, and vacuum dry at 95-100 °C for 12-20 min. After 24 hours, after calcination at a high temperature of 500-600°C, modified bamboo charcoal particles are obtained;

[0023] Wherein the preparation method of monolayer graphene oxide aqueous phase dispersion liquid is:

[0024] 60 parts by mass of graphene oxide, 20 parts of silane coupling agent and 4 parts of formaldehyde catalytic decomposition agent, wherein the formaldehyde catalytic decomposition agent is manganese acetylacetonate, and the silane coupling agent is diisopropoxylated bistrimethyl ...

Embodiment 2

[0028] A manufacturing process for a highly absorbent carbon-plastic composite material disclosed in Example 2 includes the following preparation steps:

[0029] 1) According to the number of parts by mass, take 40 parts of bamboo charcoal particles with a particle size of 60 mesh, 2 parts of nano-titanium dioxide, and 0.5 part of a single-layer graphene oxide aqueous phase dispersion, stir at room temperature for 120 min, and vacuum dry at 95-100 °C for 12-20 min. After 24 hours, after calcination at a high temperature of 500-600°C, modified bamboo charcoal particles are obtained;

[0030] Wherein the preparation method of monolayer graphene oxide aqueous phase dispersion liquid is:

[0031] 50 parts by mass of graphene oxide, 20 parts of silane coupling agent and 4 parts of formaldehyde catalytic decomposition agent, wherein the formaldehyde catalytic decomposition agent is manganese acetylacetonate, and the silane coupling agent is diisopropoxylated bistrimethyl Siloxylate...

Embodiment 3

[0035] A manufacturing process of a highly absorbent carbon-plastic composite material disclosed in Example 3 includes the following preparation steps:

[0036] 1) According to the number of parts by mass, take 40 parts of bamboo charcoal particles with a particle size of 60 mesh, 2 parts of nano-titanium dioxide, and 0.1 part of a single-layer graphene oxide aqueous phase dispersion, stir at room temperature for 120 min, and vacuum dry at 95-100 °C for 12-20 min. After 24 hours, after calcination at a high temperature of 500-600°C, modified bamboo charcoal particles are obtained;

[0037] Wherein the preparation method of monolayer graphene oxide aqueous phase dispersion liquid is:

[0038] 50 parts by mass of graphene oxide, 20 parts of silane coupling agent and 4 parts of formaldehyde catalytic decomposition agent, wherein the formaldehyde catalytic decomposition agent is manganese acetylacetonate, and the silane coupling agent is diisopropoxylated bistrimethyl Siloxylated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com