Injection-molded bicycle frame by using carbon-plastic material

A technology for injection molding and bicycles, which is applied in bicycle racks, bicycle accessories, transportation and packaging, etc., can solve the problems of high cost, low production efficiency, and non-recyclable products, and achieve the effect of low cost and accelerated popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

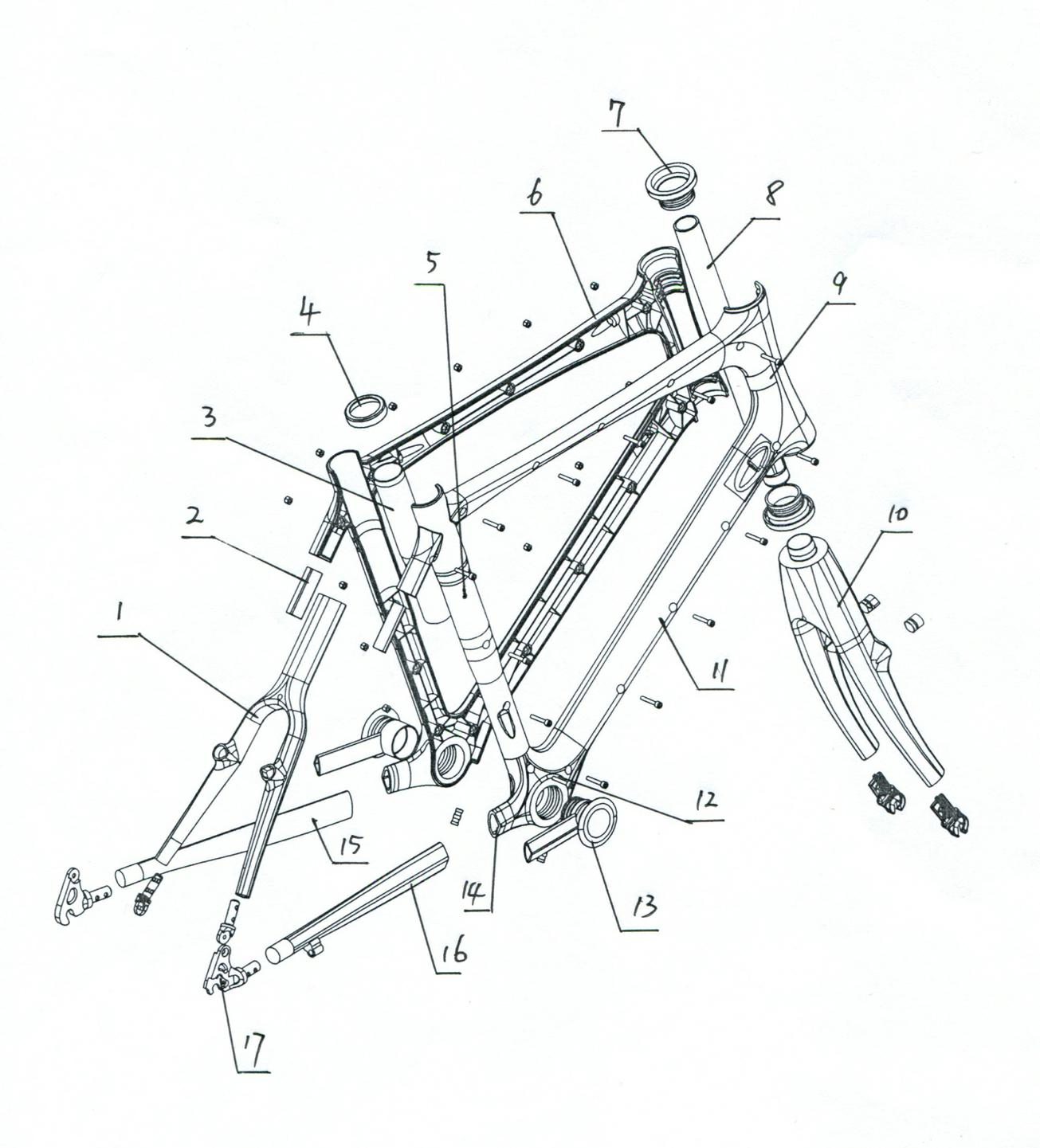

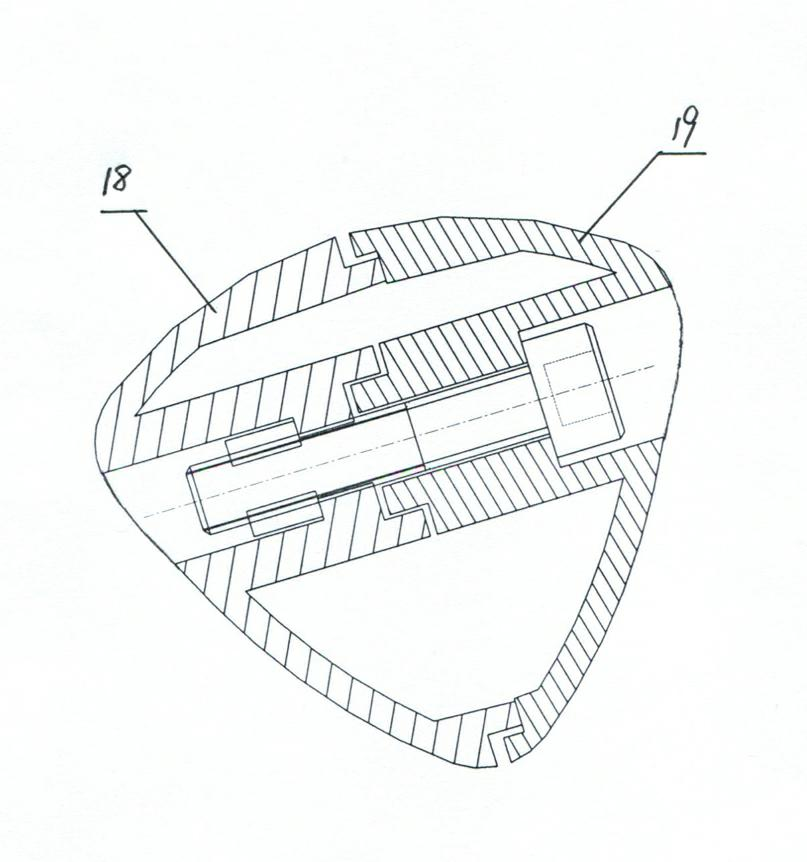

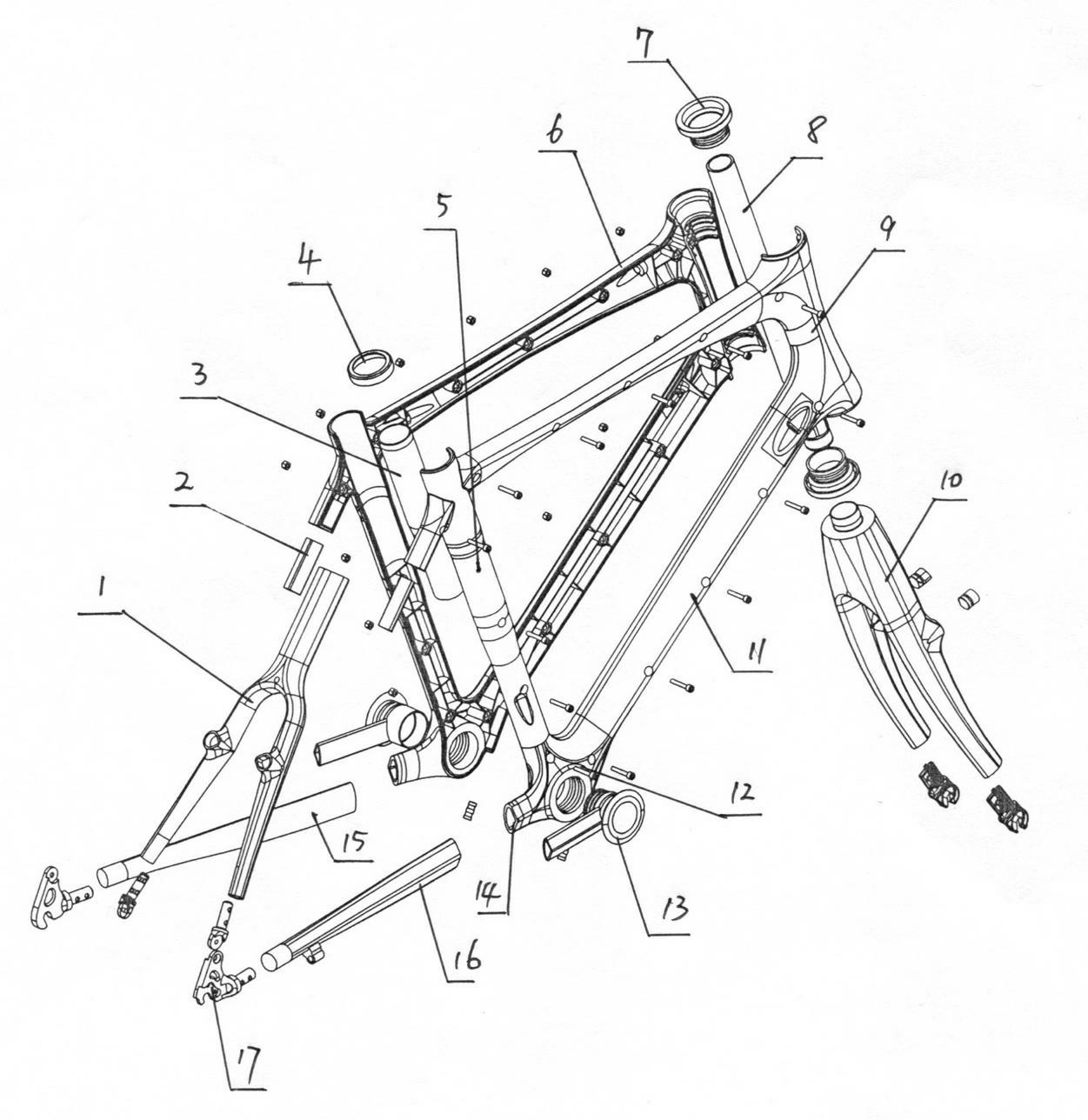

[0009] A bicycle frame made of carbon plastic material injection molding, comprising a frame body and a front fork 10, a rear upper fork 1, a rear left lower fork 15 and a rear right lower fork 16 which are integrally injection molded with carbon plastic material. The beam 6, the head tube 9, the lower beam 11, the seat tube 5 and the bottom bracket tube assembly 12, the upper and lower ends of the head tube 9 are provided with a head tube collar 7, and the upper end of the seat tube 5 is provided with a seat tube collar 4 , the frame main body is composed of the left half frame 18 and the right half frame 19, the left half frame 18 and the right half frame 19 are respectively integrally injection-molded by carbon plastic material, and the left half frame 18 and the right half frame 19 are arranged between There are cooperating buckling edges and are fixed and connected together by spaced fastening bolts. The buckling edges are coated with adhesive glue. A front inner tube 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com