Carbon plastic synthetic heat exchange material

A technology of heat exchange materials and carbon plastics, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low low temperature resistance, failure to achieve zero discharge of waste, high cost, etc., achieve low temperature resistance and heat conduction effect, improve Corrosion resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

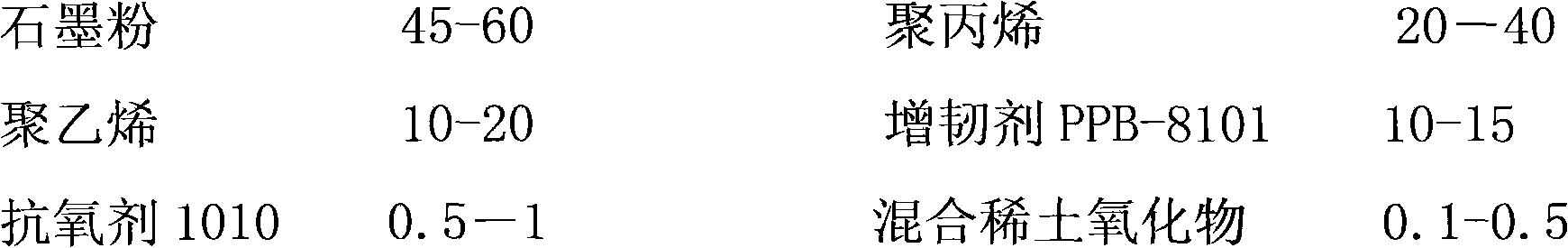

[0027] Embodiment 1 (unit kg)

[0028]

[0029]

[0030] Its preparation method is as follows:

[0031] Weigh each raw material according to the formula amount, mix at high speed for 2 minutes, then enter into a banbury mixer for banbury mixing, the temperature is 290°C, the banbury mixing time is 80 seconds, and then the calender is rolled and discharged, and finally cold cut into columnar granules to obtain.

Embodiment 2

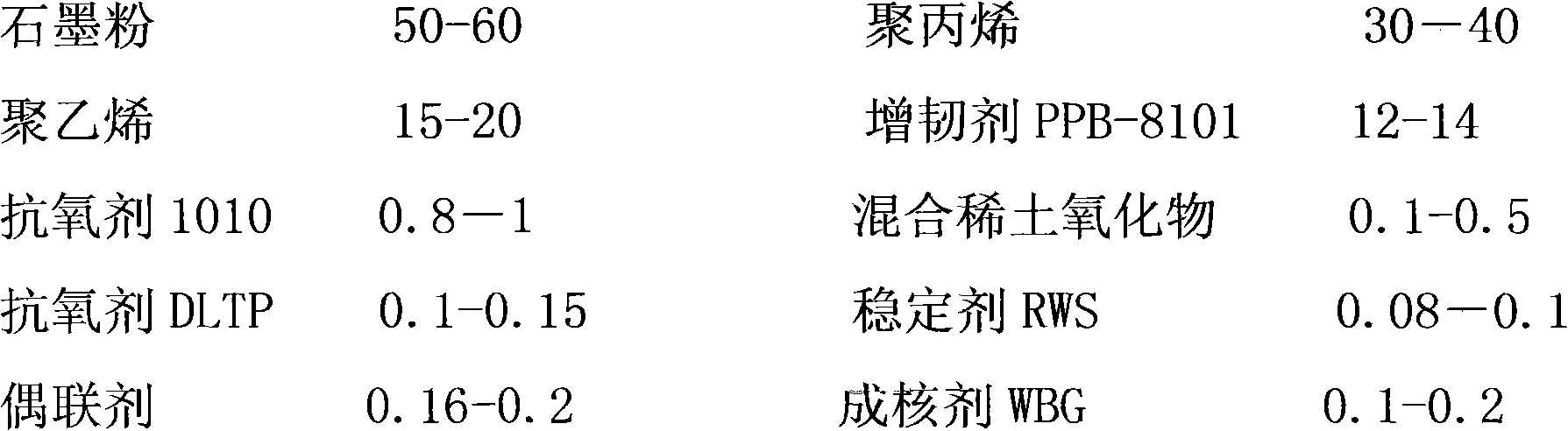

[0032] Embodiment 2 (unit kg)

[0033]

[0034] Weigh each raw material according to the formula amount, mix at high speed for 2 minutes, then enter into a banbury mixer for banbury mixing, the temperature is 295°C, the banbury mixing time is 60 seconds, and then the calender is rolled and discharged, and finally cold cut into columnar granules to obtain.

Embodiment 3

[0035] Embodiment 3 (unit kg)

[0036]

[0037] Its preparation method is as embodiment 1.

[0038] The effect of the heat sink made of the environmental-friendly plastic-based heat-conducting material according to Embodiment 1 of the present invention will be described below through the test report.

[0039] Tsinghua University Building Environment Testing Center

[0040] Radiator Performance Test Report

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com