Carbon-plastic composite floor and manufacturing method thereof

A compound flooring and manufacturing method technology, applied in building structure, floor, building, etc., can solve the problems affecting indoor beauty and sanitation cleaning, and achieve the effect of low cost and pollution elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

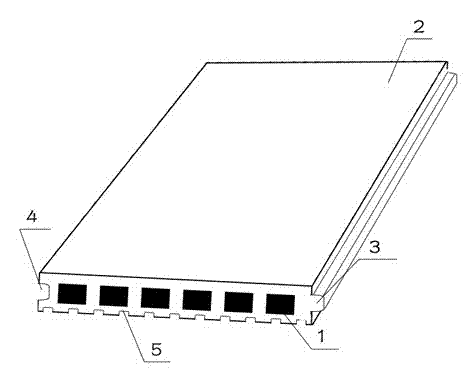

[0018] combine figure 1 can be seen:

[0019] Among the figure, 2 is the front of the plastic hollow floor, 5 is the back of the floor, and 3 and 4 are the interface of the floor. One of the places in the picture was originally a number of holes in the plastic hollow floor, and the blackening indicates that it has been filled with formed activated carbon.

[0020] The ingredient ratio of shaped activated carbon is: 7 parts of activated carbon powder + 3 parts of ordinary cement, plus 30-35% of water. The specific steps are: first weigh the activated carbon and cement according to the above ratio and mix them evenly, then gradually add water and mix thoroughly to form a slurry, erect the floor, pour the slurry into the cavity and let it stand for 24 hours, and then maintain it indoors for more than 7 days. After the slurry solidifies, clean the surface neatly and cleanly.

Embodiment 2

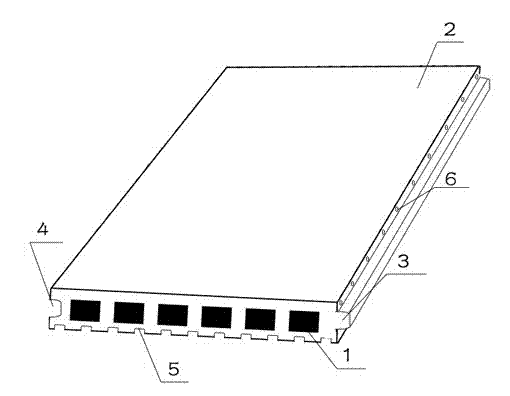

[0022] combine figure 2 can be seen:

[0023] Similar to Example 1, in order to improve the air permeability of the carbon-plastic composite floor, some small holes can be drilled in the floor joint 6 and the back to communicate with the activated carbon in the hole. In addition, in order to improve efficiency, shaped activated carbon can also be prepared from plaster of paris. The ingredient ratio of shaped activated carbon is: 6 parts of activated carbon powder + 4 parts of plaster of paris, plus 30-35% of water. The specific steps are: first weigh the activated carbon and the plaster of paris according to the above ratio and mix them evenly, then gradually add water and mix thoroughly to form a slurry, erect the floor, inject the slurry into the cavity and let it stand for 24 hours, and wait for the slurry to solidify. Surface cleaning is regular and clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com