Method for preparing hardened and wear-resistant optical thin film through one-step co-extrusion stretching

An optical thin film and functional technology, applied in the field of optical materials, can solve problems such as difficult processing, weak functionality, constraints on organic materials and inorganic materials, etc., and achieve low haze and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

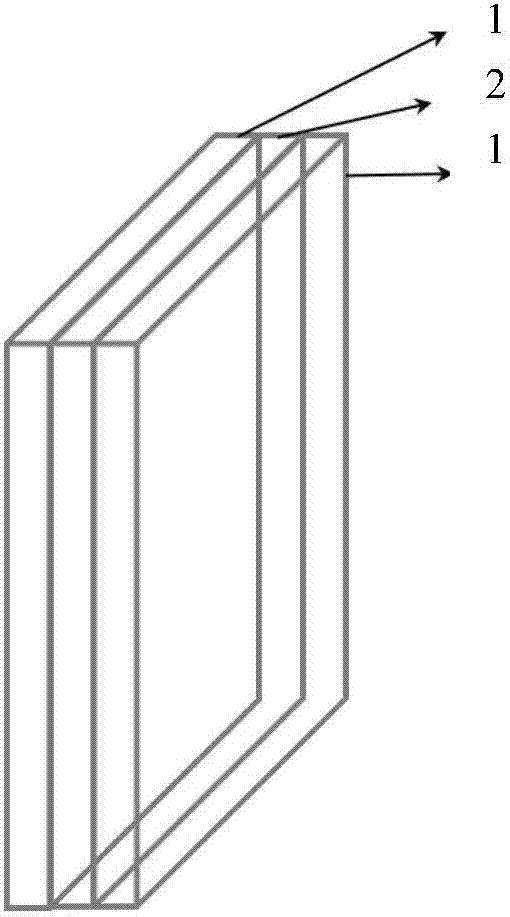

Image

Examples

Embodiment 1

[0030] Step (1) preparing a dispersion color paste with a hardening and wear-resisting function.

[0031] Take 10 parts of nano-silica, 89 parts of isopropanol, and 1 part of PEG dispersant into a stainless steel container, pre-disperse in a high-speed shear disperser at 1500r / min for 30 minutes; then put it into a ball mill and mill for 24 Hours, sieve to remove large particles, to obtain evenly dispersed nano-color paste of silicon oxide.

[0032] step (2)

[0033] Blend the above-prepared nano-color paste with PET masterbatch, heat, melt, stir and disperse in a screw granulator, then extrude, cool, and granulate to obtain an organic-inorganic PET composite masterbatch with hardening and wear resistance.

[0034] step (3)

[0035] When preparing a hardening and wear-resistant optical film, the organic-inorganic PET composite masterbatch with hardening and wear-resisting functions was dried in an oven at 120°C for 24 hours, and mixed with Daguang PET particles at a mass add...

Embodiment 2

[0038] Step (1) preparing a dispersion color paste with a hardening and wear-resisting function.

[0039] Take 10 parts of nano-zirconia, 89 parts of isopropanol, and 1 part of PEG dispersant into a stainless steel container, pre-disperse in a high-speed shear disperser at 1500r / min for 30 minutes; then put it into a ball mill and mill for 24 hours, sieve to remove large particles, and obtain uniformly dispersed zirconia nano-color paste.

[0040] step (2)

[0041] Blend the above-prepared nano-color paste with PET masterbatch, heat, melt, stir and disperse in a screw granulator, then extrude, cool, and granulate to obtain an organic-inorganic PET composite masterbatch with hardening and wear resistance.

[0042] step (3)

[0043] When preparing a hardening and wear-resistant optical film, the organic-inorganic PET composite masterbatch with hardening and wear-resisting functions was dried in an oven at 120°C for 24 hours, and mixed with Daguang PET particles at a mass addit...

Embodiment 3

[0046] Step (1) preparing a dispersion color paste with a hardening and wear-resisting function.

[0047] Take 10 parts of nano-alumina, 89 parts of isopropanol, and 1 part of PEG dispersant into a stainless steel container, pre-disperse in a high-speed shear disperser at 1500r / min for 30 minutes; then put it into a ball mill for 24 minutes Hours, sieve to remove large particles, to obtain uniformly dispersed alumina nano-color paste.

[0048] step (2)

[0049] Blend the above-prepared nano-color paste with PET masterbatch, heat, melt, stir and disperse in a screw granulator, then extrude, cool, and granulate to obtain an organic-inorganic PET composite masterbatch with hardening and wear resistance.

[0050] step (3)

[0051] When preparing a hardening and wear-resistant optical film, the organic-inorganic PET composite masterbatch with hardening and wear-resisting functions was dried in an oven at 120°C for 24 hours, and mixed with the large glossy PET particles at a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com