Colored permeable pavement material and preparation process thereof

A technology for permeable pavement and pavement materials, which is applied in the field of pavement materials to achieve the effects of improving compressive capacity, not easily crushed, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

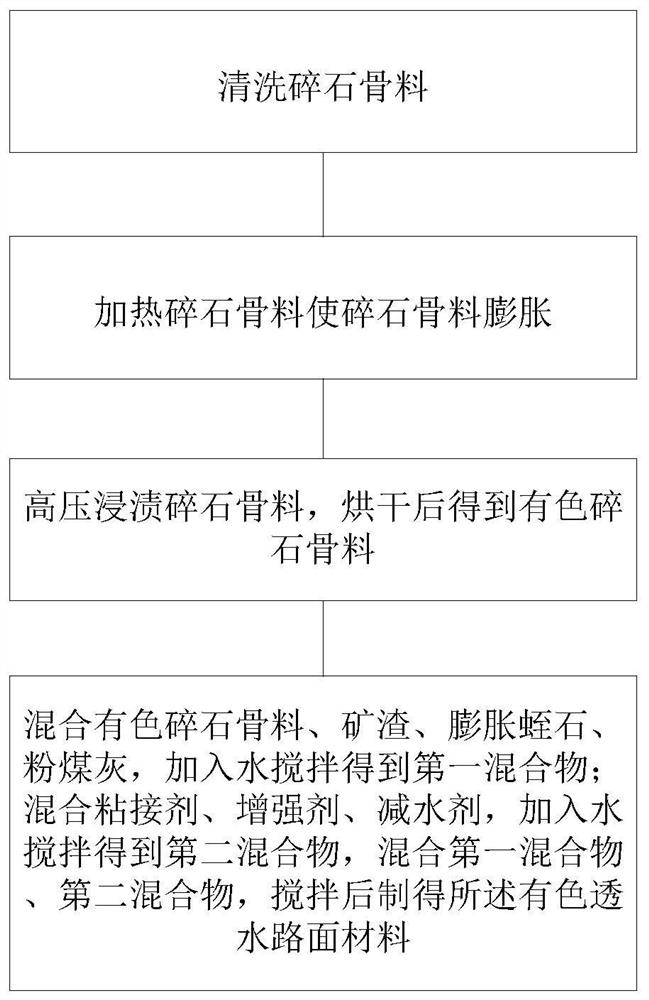

Method used

Image

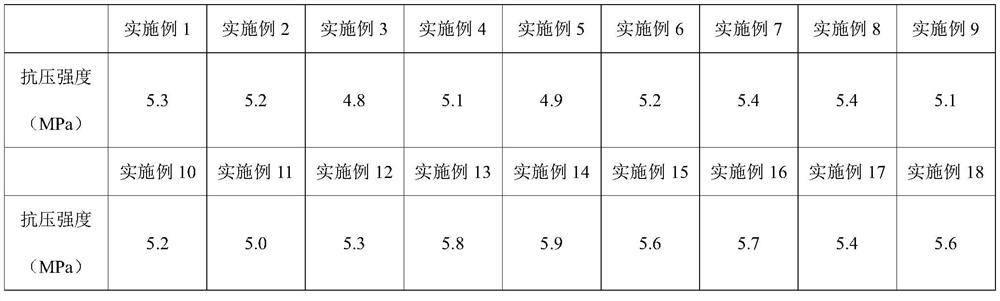

Examples

Embodiment 1

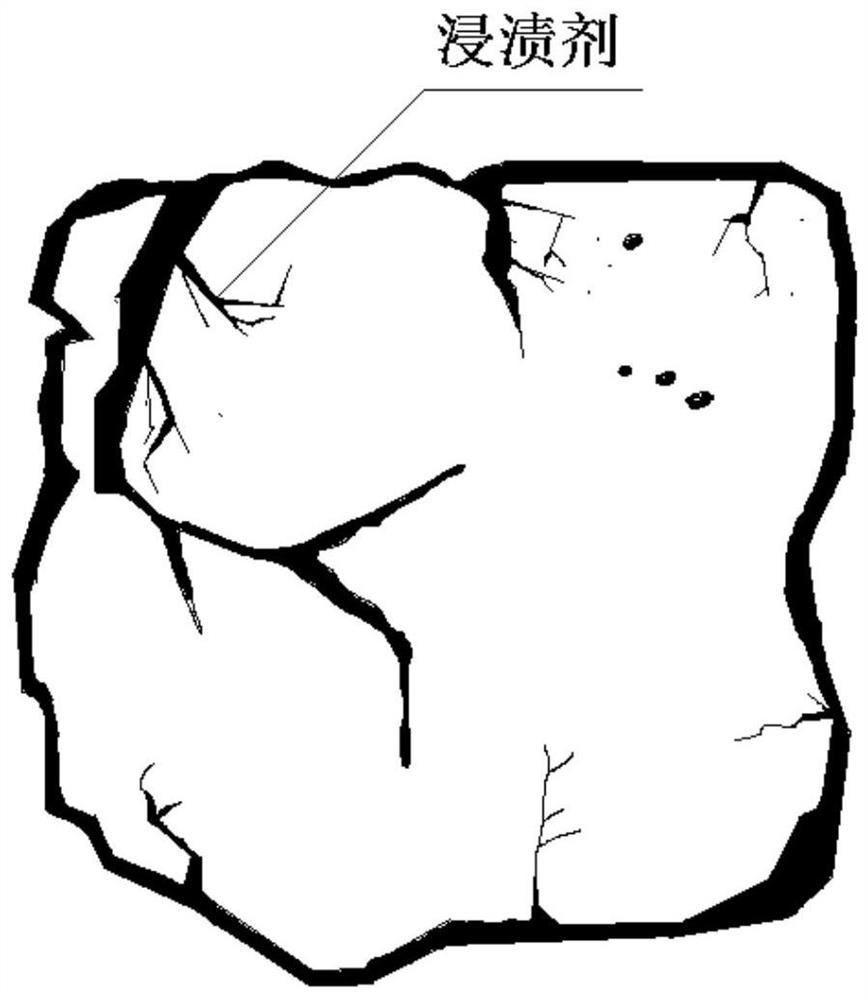

[0051] Clean and crush the crushed stone aggregates and air-dry the crushed stone aggregates, heat to remove the moisture on the surface of the crushed stone aggregates and in the gaps, so that the crushed stone aggregates are heated and expand, and stir the expanded crushed stone aggregates at a constant temperature material, while spraying an impregnating agent to the crushed stone aggregate, the spraying amount of the impregnating agent is greater than the impregnating dose required to cover the surface and gaps of the crushed stone aggregate, and then drying to obtain colored crushed stone aggregate;

[0052] Mix the colored crushed stone aggregate, slag, expanded vermiculite, and fly ash, add water and stir to obtain the first mixture; mix the adhesive, reinforcing agent, and water reducing agent, add water and stir to obtain the second mixture, and mix The first mixture and the second mixture are stirred to obtain the colored water-permeable pavement material C1;

[0053...

Embodiment 2- Embodiment 6

[0055] The preparation method of embodiment 2-embodiment 6 is the same as embodiment 1.

Embodiment 2

[0056] The raw materials of the colored permeable pavement material C2 in Example 2 include the following components: 550 parts of colored crushed stone aggregate, 20 parts of slag, 15 parts of expanded vermiculite, 10 parts of fly ash, 180 parts of adhesive, and 20 parts of reinforcing agent , 15 parts of water reducer, 200 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com