Composite bipolar board for fuel cell and preparation method and application of composite bipolar board

A bipolar plate and conductive filler technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced bipolar plate cost, complex preparation process, low production efficiency, etc., and achieve good product quality, simple equipment requirements, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

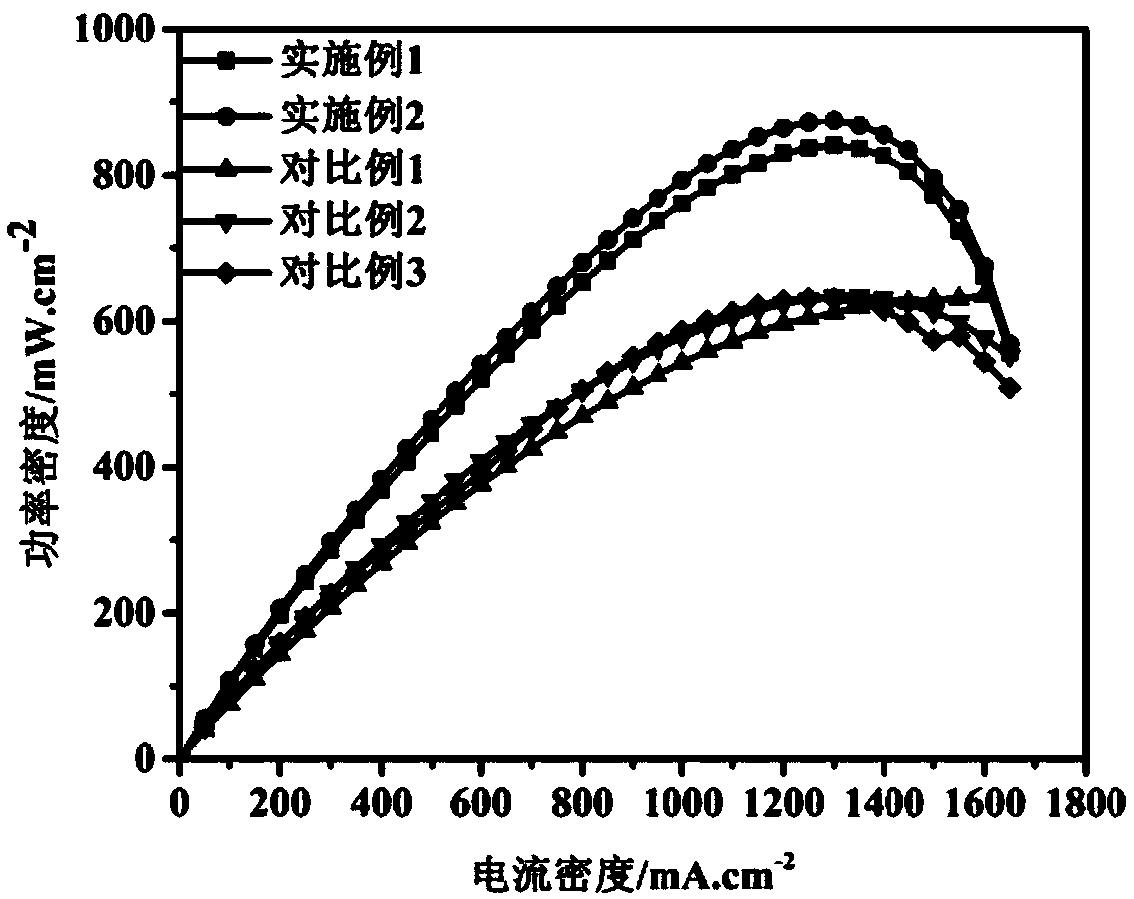

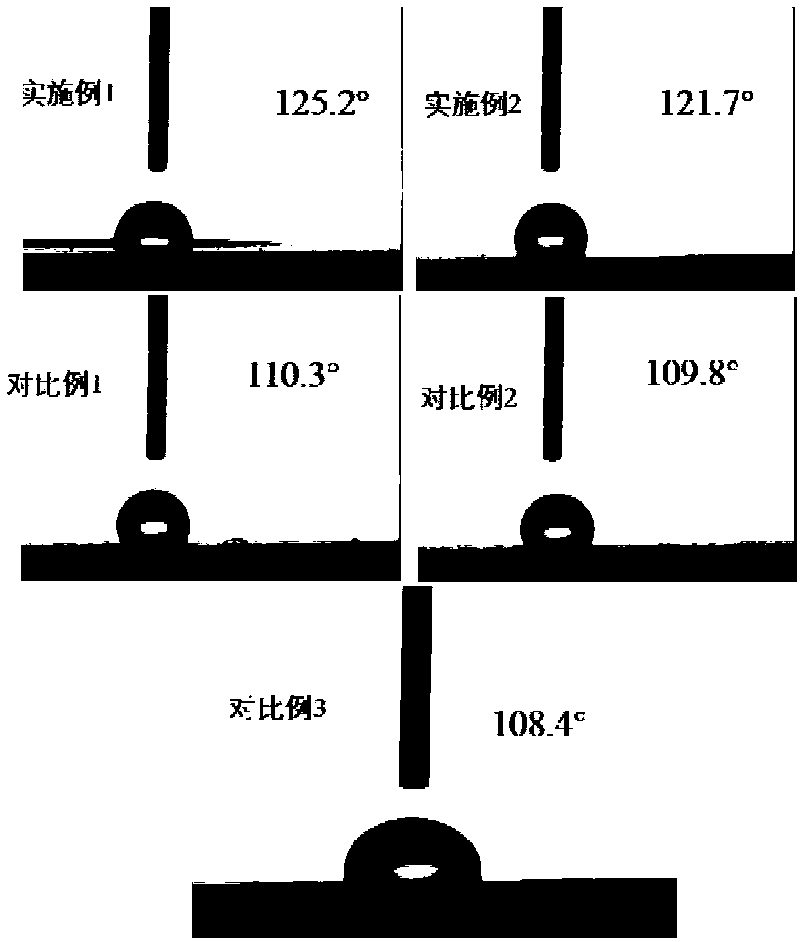

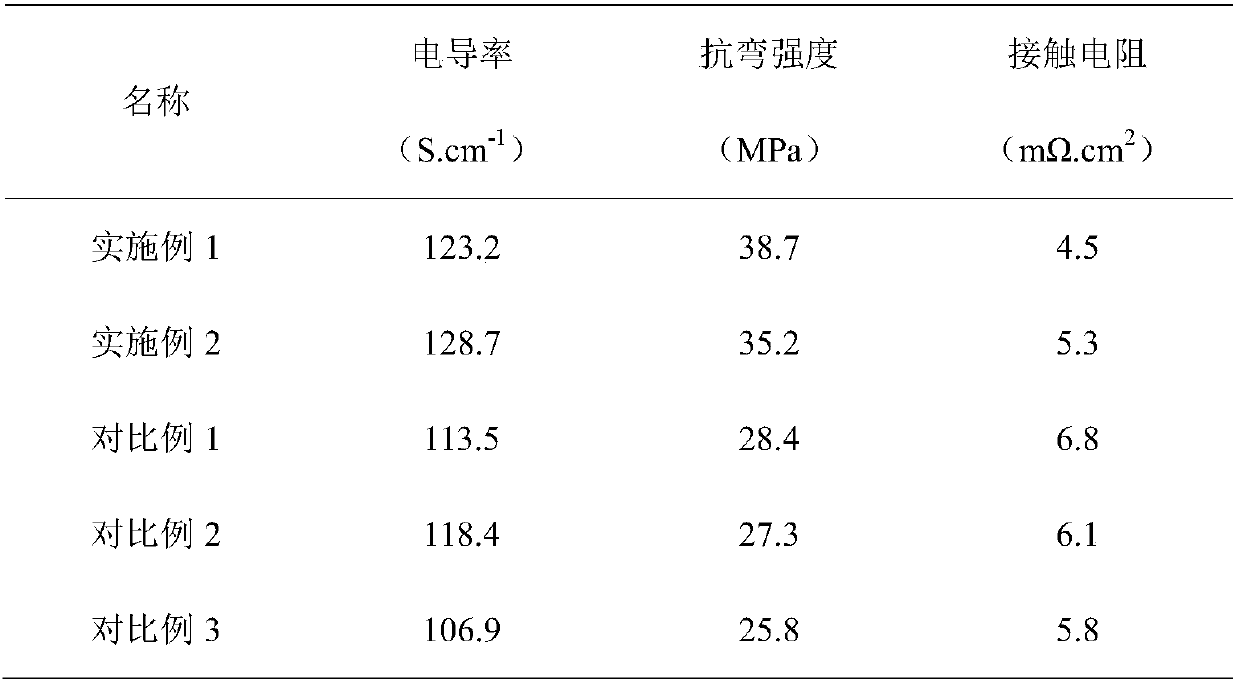

Embodiment 1

[0028] Take by weighing respectively PMMA resin (molecular weight is 85,000) 0.8kg, PS resin (molecular weight is 200,000) 0.6kg, SEBS resin (styrene content 15%, melt index is 5g / 10min under 200 ℃) 0.2kg, graphite powder ( Purity 99.95%, 400 mesh) 9.4kg, carbon fiber (diameter is 5 μm, aspect ratio is 20) 0.4kg, join in the ball mill, ball mill temperature is room temperature, ball mill speed is 30r / min, ball mill time 10min. Then transfer the homogeneously mixed material to a mold with a flow field, the pre-compression pressure is 40MPa, The molding time is 15min. Finally, the temperature of the mold is lowered to room temperature by circulating water cooling, and the carbon / polymer composite bipolar plate is obtained by releasing the pressure and demoulding.

Embodiment 2

[0030] Take by weighing respectively PMMA resin (molecular weight is 100,000) 0.6kg, PS resin (molecular weight is 200,000) 0.8kg, SEBS resin (styrene content 10%, melt index is 9g / 10min under 200 ℃) 0.2kg, graphite powder ( Purity 99.95%, 400 mesh) 9.6kg, carbon fiber (diameter is 5 μ m, aspect ratio is 20) 0.4kg, join in the ball mill, ball mill temperature is room temperature, ball mill speed is 50r / min, ball mill time 8min. Then transfer the homogeneously mixed material to a mold with a flow field, the pre-compression pressure is 80MPa, The molding time is 20min. Finally, the temperature of the mold is lowered to room temperature by circulating water cooling, and the carbon / polymer composite bipolar plate is obtained by releasing the pressure and demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com