Preparation method of graphene composite anticorrosive coating

A graphene composite, anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, electrolytic coatings, etc., can solve problems such as lasting protection of metal substrates, coating thickness, uniformity limitations, and limited corrosion protection capabilities, and achieve long-term Effective protective effect, simple and easy preparation process, stable protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

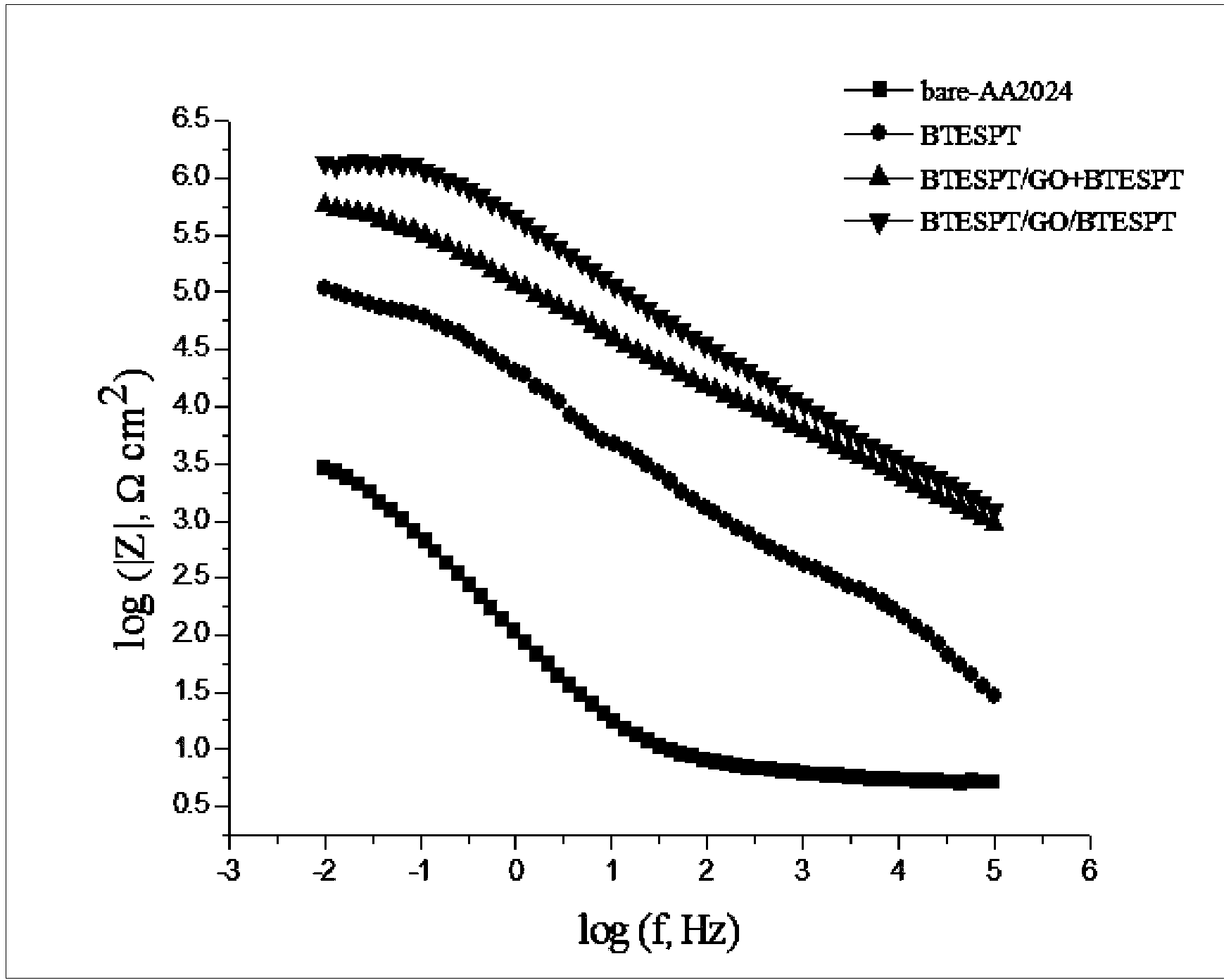

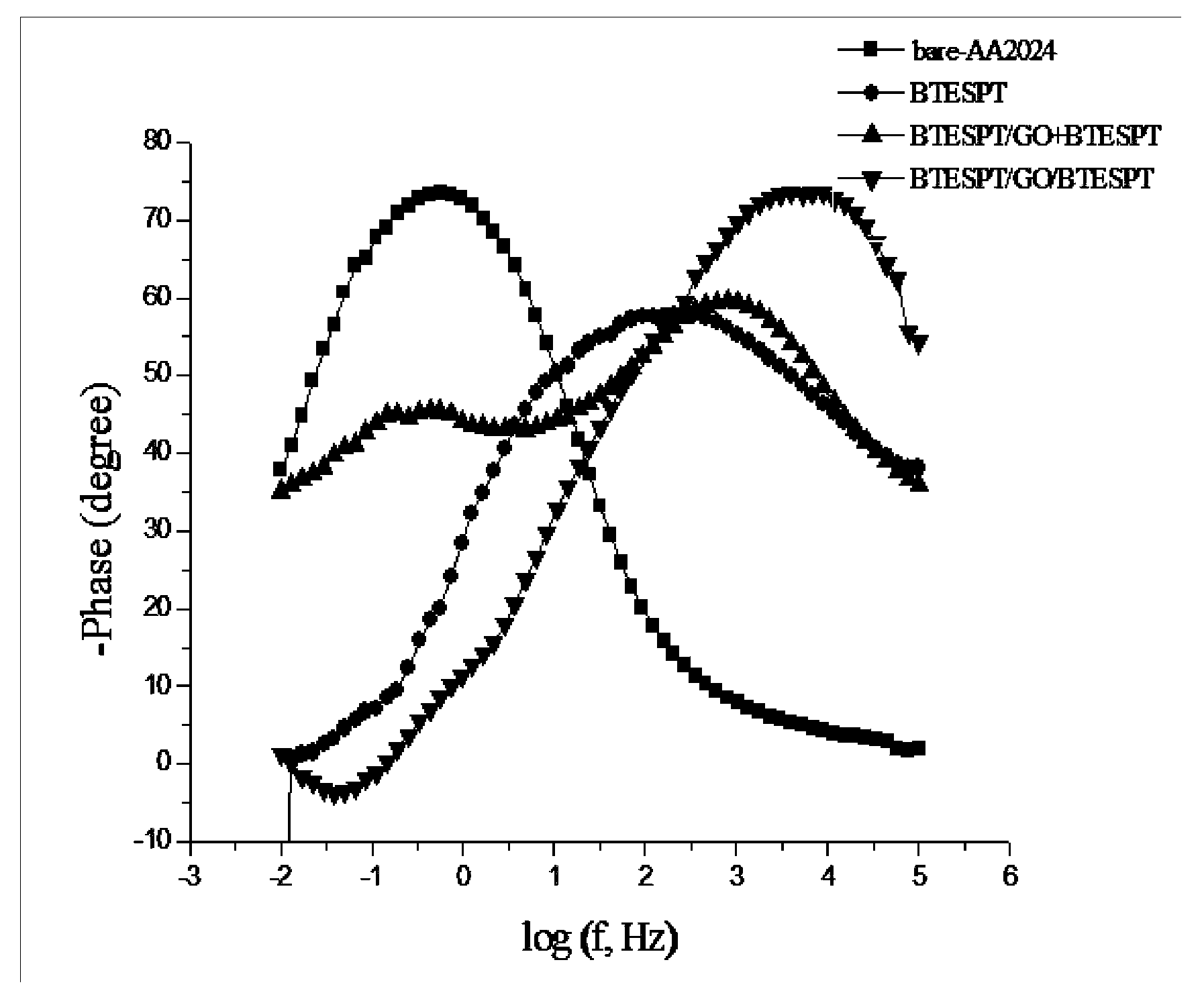

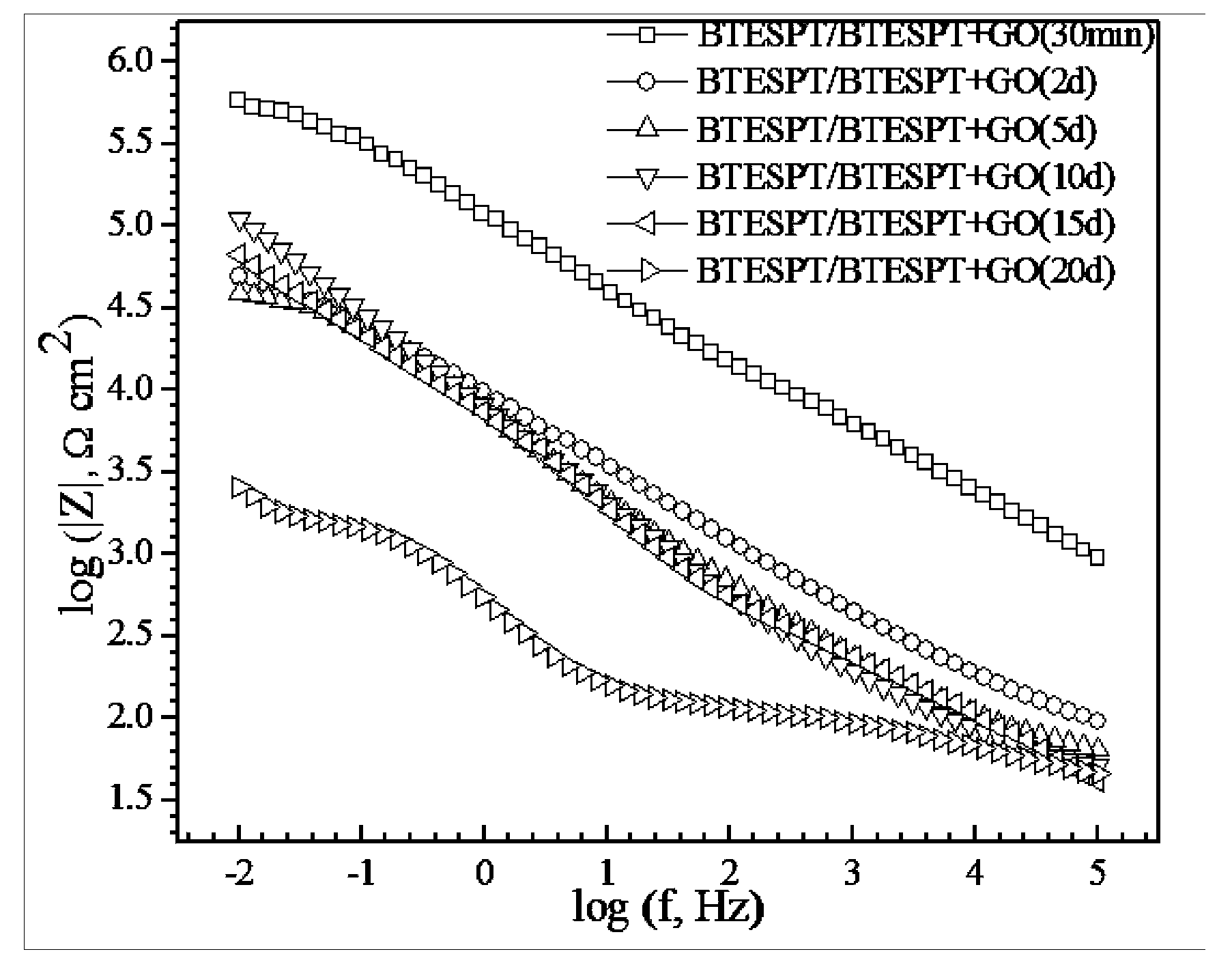

[0039] Example 1: Graphene oxide was added to the silane coupling agent on the surface of 2024Al alloy to prepare a graphene oxide composite anti-corrosion coating.

[0040] (1) Prepare 4 wt of bis-[3-(triethoxy)silylpropyl]tetrasulfide (BTESPT) silane solution. BTESPT: deionized water: absolute ethanol volume ratio is 4:6:90, adjust the pH to 4.5 with glacial acetic acid.

[0041] (2) Prepare oxidation-modified modified graphene solution. Weigh an appropriate amount of graphene oxide and dissolve it in an appropriate amount of deionized water to a concentration of 1.0 mg / ml.

[0042] (3) Metal surface pretreatment. The area of the 2024Al alloy is 1.25cm2. Before film formation, the 2024Al alloy is polished sequentially with metallographic sandpaper of different meshes, and polished with a metallographic polishing machine. Oil cleaning, and then welded on the copper wire with solder, and finally the other surfaces except the deposition surface are sealed with epoxy resin....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com