Process for preparing nanometer cobalt oxide

A technology of nano-cobalt oxide and cobalt oxide, applied in nanostructure manufacturing, cobalt oxide/cobalt hydroxide, nanotechnology, etc., can solve the problems of reagent types or steps, inconvenient operation and actual production, etc., and achieve simple and easy operation of equipment , to achieve the effect of controllable preparation and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

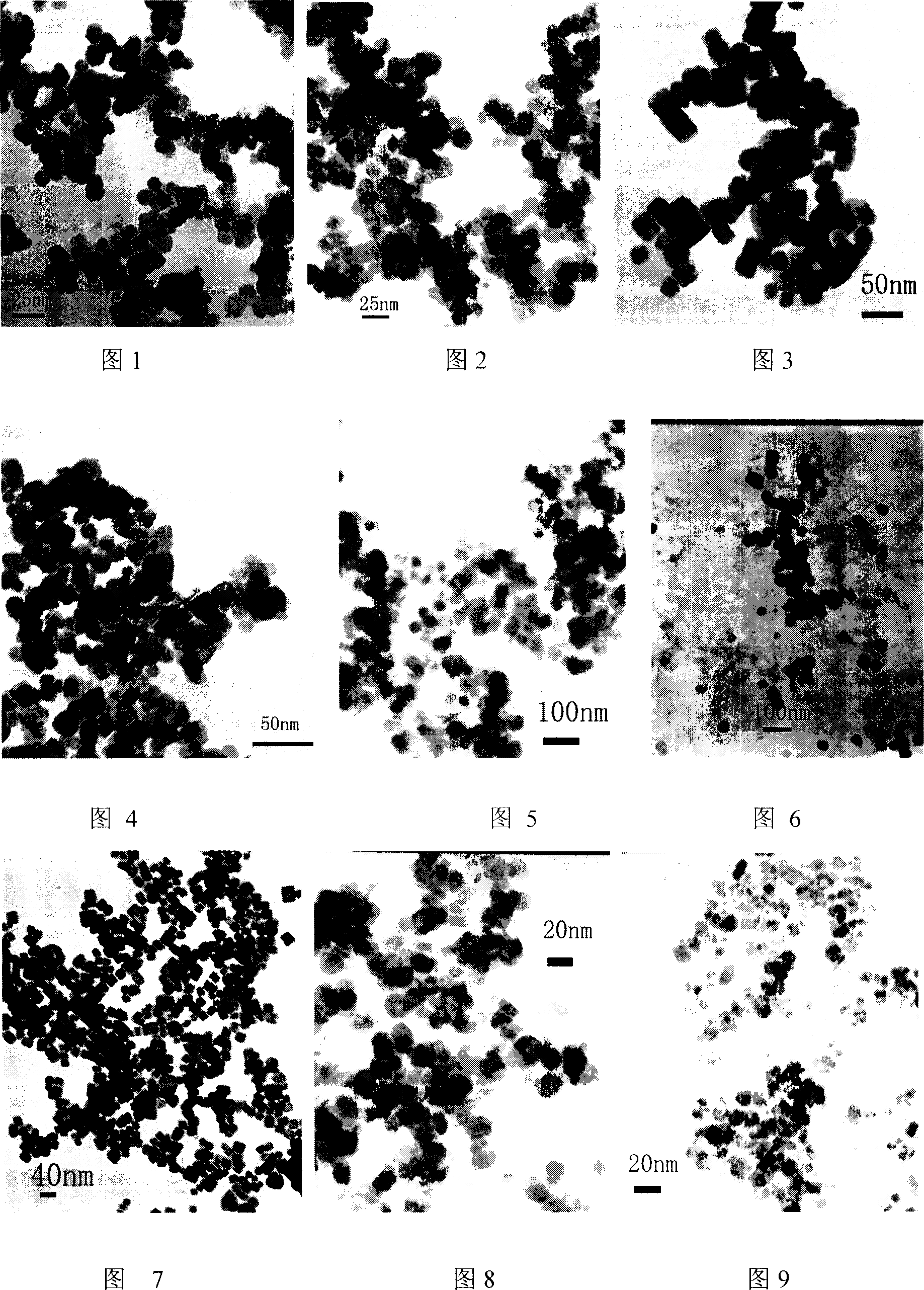

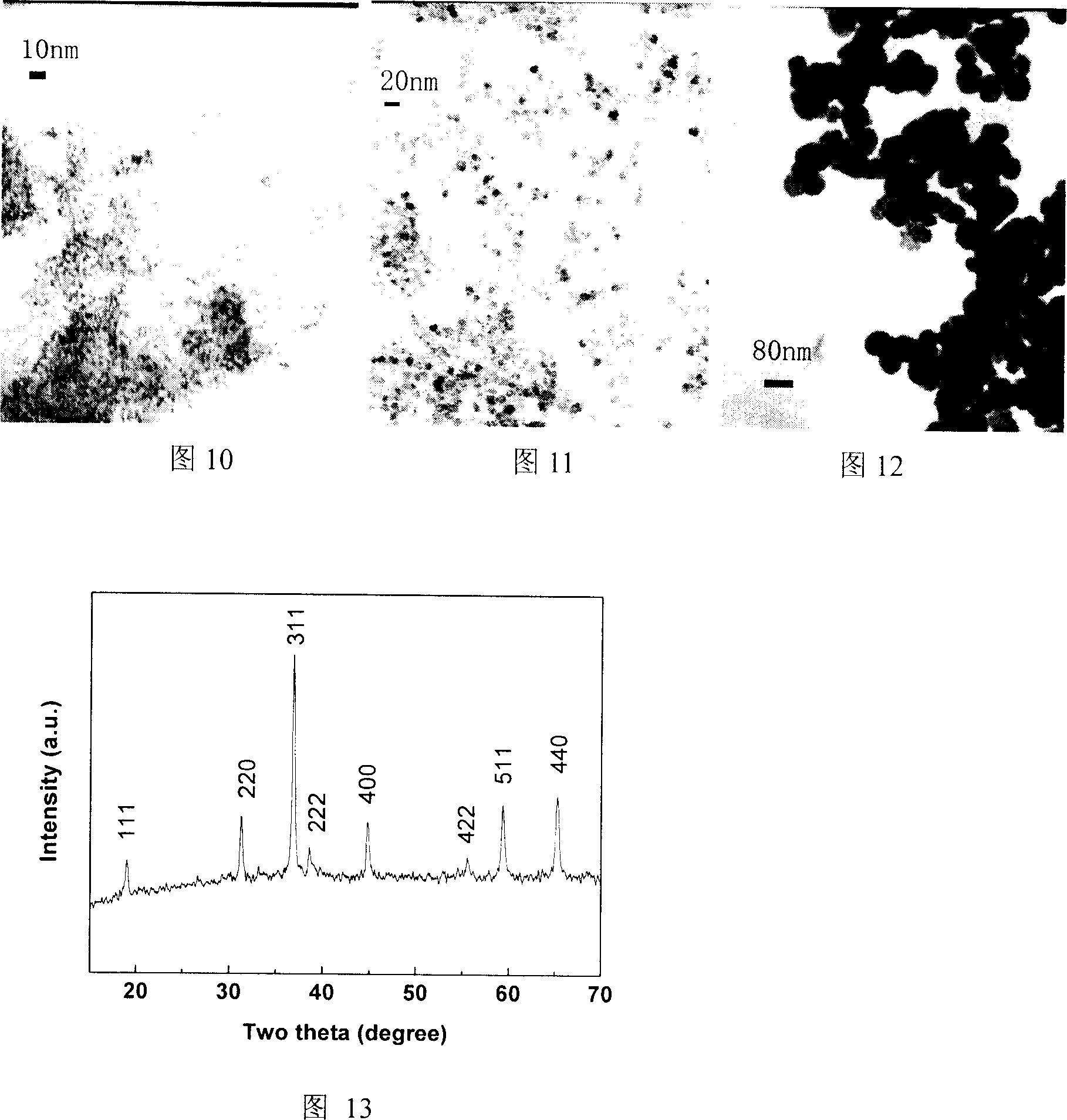

Embodiment 1

[0034] Take 0.50gCo(CH 3 COO) 2 4H 2 O was dissolved in 20ml of water, 2.5ml of 25% concentrated ammonia water was added thereto, stirred and refluxed at 70°C for 3 hours, a certain amount of air was retained in the upper part of the solution during the reflux reaction, the resulting suspension was centrifuged, washed several times with distilled water, Cobalt oxide nanoparticles with an average particle diameter of about 15 nm can be obtained by medium drying.

Embodiment 2

[0036] Take 0.56gCoSO 4 7H 2 O was dissolved in 20ml of water, 2.5ml of 25% concentrated ammonia water was added thereto, stirred evenly in the air, transferred to a closed reaction kettle, a certain amount of air was kept in the upper part of the solution, reacted at 100°C for 3 hours, and the resulting suspension was centrifuged, Washing with distilled water for several times and drying in air can obtain cobalt oxide nanoparticles with an average particle diameter of about 20 nm.

Embodiment 3

[0038] Take 0.50gCo(CH 3 COO) 2 4H 2 O was dissolved in 20ml of water, 2.5ml of 25% concentrated ammonia water was added thereto, stirred evenly in the air, transferred to a closed reaction kettle, a certain amount of air was kept in the upper part of the solution, reacted at 200°C for 8 hours, and the resulting suspension was centrifuged, Washing with distilled water for several times and drying in the air can obtain cobalt oxide nanocubic crystals with an average particle diameter of about 25 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com