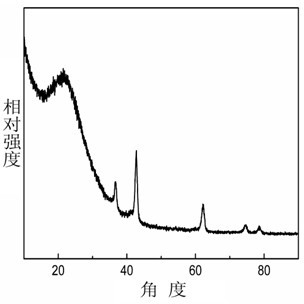

Porous titanium nitride nanotube array film and preparation method thereof

A technology of nanotube array and titanium nitride, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., to achieve the effect of increasing specific surface area, improving electrochemical performance, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

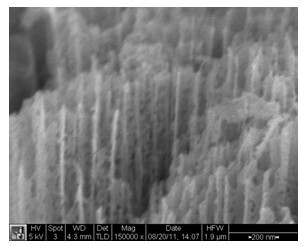

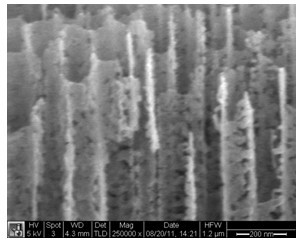

[0028] A porous titanium nitride nanotube array film and a preparation method thereof. First put the polished and polished titanium-containing metal sheet as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40~60V, and the anodic oxidation time is 0.5~2.0 hours; then the anodized titanium-containing metal Clean the sheet, dry it, then anneal the dried titanium-containing metal sheet in air at 300-400°C, and finally place the annealed titanium-containing metal sheet at 300-450°C in nitrogen-containing Annealing is carried out at a speed of 12-20 DEG C / min in an atmosphere with a volume content of 10-40% of the precursor, and the titanium nitride nanotube array film is obtained on the surface of the titanium-containing metal sheet by cooling with the furnace.

[0029] In this embodiment: the titanium content of the titanium-containing metal sheet is 50-70 wt%; the electrolyte is 0.05-0.5 wt% of fluorine-containing ions, 0.5-5 wt% of H 2 A mixe...

Embodiment 2

[0031] A porous titanium nitride nanotube array film and a preparation method thereof. First put the polished and polished titanium-containing metal sheet as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40~60V, and the anodic oxidation time is 0.5~2.0 hours; then the anodized titanium-containing metal Clean the sheet, dry it, then anneal the dried titanium-containing metal sheet in the air at 350-450°C, and finally place the annealed titanium-containing metal sheet at 400-600°C in nitrogen-containing Annealing is carried out at a speed of 3-10° C. / min in an atmosphere with a volume content of 20-60 percent of the precursor, and the titanium nitride nanotube array film is obtained on the surface of the titanium-containing metal sheet by cooling with a furnace.

[0032] In this embodiment: the titanium content of the titanium-containing metal sheet is 60-80 wt%; the electrolyte is 0.3-0.8 wt% of fluorine-containing ions, 2-15 wt% of H 2 A ...

Embodiment 3

[0034] A porous titanium nitride nanotube array film and a preparation method thereof. First put the polished and polished titanium-containing metal sheet as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40~60V, and the anodic oxidation time is 0.5~2.0 hours; then the anodized titanium-containing metal The sheet is cleaned and dried, and then the dried titanium-containing metal sheet is annealed in the air at 500-600 °C, and finally the annealed titanium-containing metal sheet is placed in a nitrogen-containing environment at 550-700 °C Annealing is carried out at a speed of 9-15° C. / min in an atmosphere with a volume content of 50-90 percent of the precursor, and the titanium nitride nanotube array film is obtained on the surface of the titanium-containing metal sheet by cooling with the furnace.

[0035] In this embodiment: the titanium content of the titanium-containing metal sheet is 80-95 wt%; the electrolyte is 0.8-3.0 wt% of fluorin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com