Preparation method of three-dimensional porous silica powder

A technology of three-dimensional porous and porous silicon, which is applied in electrical components, battery electrodes, nanotechnology, etc., can solve the problems of low production cost, harsh preparation process, and restrictions on the large-scale commercial application of powdery porous silicon, and achieve operational Ease, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

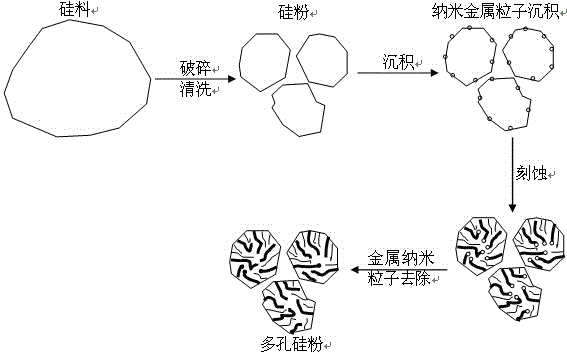

[0022] The preparation method of the three-dimensional porous silicon powder described in this embodiment specifically includes the following steps (such as figure 1 said):

[0023] (1) Pretreatment of silicon material: The bulk silicon material (metallurgical grade silicon, silicon purity: 98.8wt%) was crushed and ground (38~75μm), washed with deionized water for 5 times, and then washed with 5wt% HF Soak the cleaned silicon powder for 40min, and dry it for later use;

[0024] (2) Etching of silicon powder: A one-step metal nanoparticle-assisted etching method was used at 10 °C, and the silicon powder was placed in HF acid and AgNO. 3 In the mixed solution (the liquid-solid ratio of silicon material and etching solution is 5:1), the concentration of HF in the mixed solution is 0.1mol / L, AgNO 3 The concentration of silicon dioxide was 10 mol / L, and the reaction system was placed in a dark room and stirred (rotation speed: 120 rpm) for 50 min to obtain large-scale silicon par...

Embodiment 2

[0028] The preparation method of the three-dimensional porous silicon powder described in this embodiment specifically includes the following steps:

[0029] (1) Pretreatment of silicon material: The bulk silicon material (solar grade polysilicon, silicon purity: 99.99wt%) was crushed and ground (38~75μm), washed with deionized water for 5 times, and then washed with 20wt% HF Soak the cleaned silicon powder for 1min, and dry it for later use;

[0030] (2) Etching of silicon powder: a one-step metal nanoparticle-assisted etching method was used at 50 °C, and the silicon powder was placed in HF acid and KAuCl. 4 In the mixed solution (the liquid-solid ratio of silicon material and etching solution is 6:1), the concentration of HF in the mixed solution is 33mol / L, KAuCl 4 The concentration of silicon dioxide was 0.001 mol / L, and the reaction system was stirred (rotation speed: 120 rpm) for 600 min to obtain large-scale silicon particles containing nano-scale pores;

[0031] (3)...

Embodiment 3

[0034] The preparation method of the three-dimensional porous silicon powder described in this embodiment specifically includes the following steps:

[0035] (1) Pretreatment of silicon material: The bulk silicon material (single crystal silicon, silicon purity > 99.99999wt%) is crushed and ground (38~75μm), washed with deionized water for 5 times, and then washed with 30wt% HF Soak the cleaned silicon powder for 20min, and dry it for later use;

[0036] (2) Etching of silicon powder: a one-step metal nanoparticle-assisted etching method was used at 20 °C, and the silicon powder was placed in HF acid and H 2 PtCl 6 In the mixed solution (the liquid-solid ratio of silicon material and etching solution is 6:1), the concentration of HF in the mixed solution is 18mol / L, H 2 PtCl 6 The concentration of silicon dioxide was 4 mol / L, and the reaction system was stirred (rotation speed: 120 rpm) for 500 min to obtain large-scale silicon particles containing nano-scale pores;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com