Preparation method of self-assembly Ni-MOFs electrochromic QR code device

An electrochromic and self-assembly technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of high equipment and substrates, and achieve the effect of low cost, low driving voltage, and maintaining the color unchanged for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

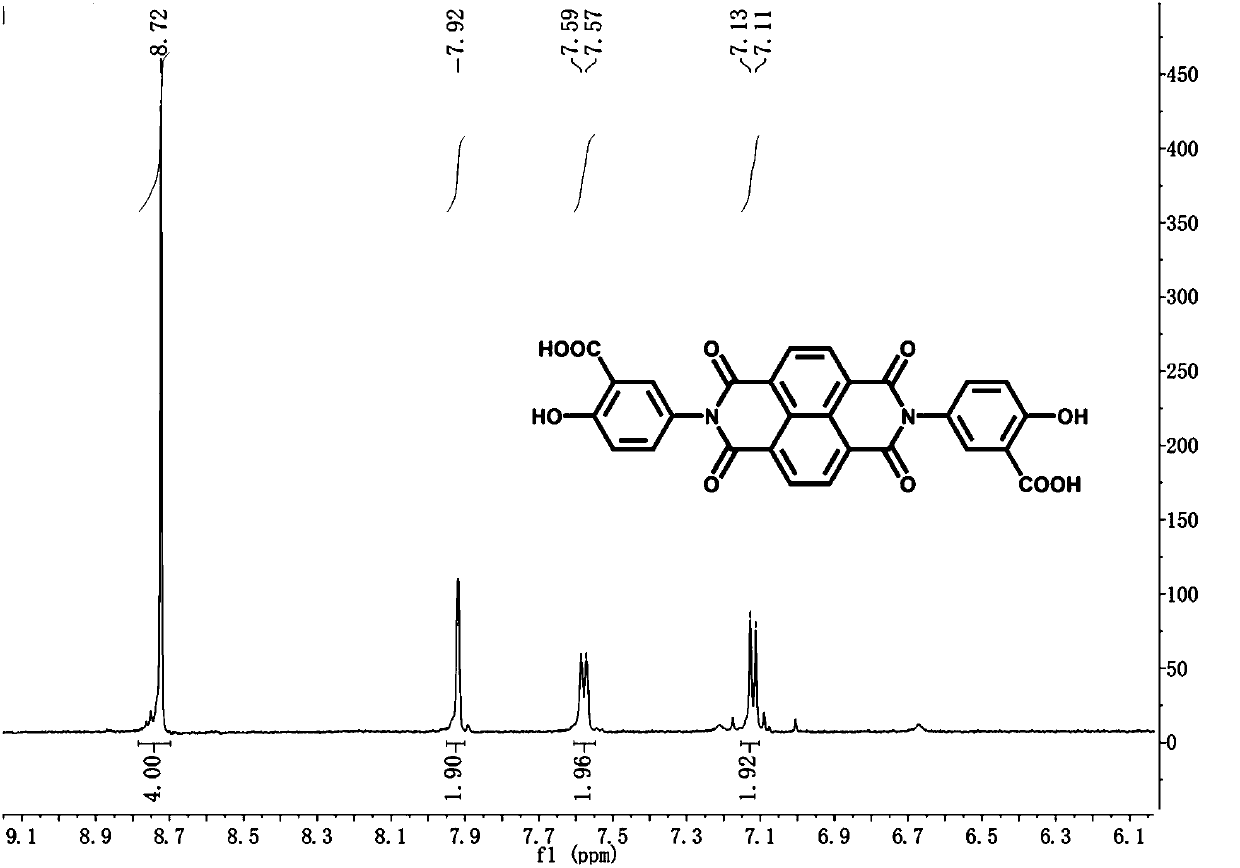

[0034] (1) Dissolve 3mmol 1,4,5,8-naphthalene tetracarboxylic anhydride and 4.4mmol 5-amino-2-hydroxybenzoic acid in 100mL toluene and react at 150°C for 12h, then filter, wash with 1mol / L hydrochloric acid, and dry , the naphthalene tetracarboxylic anhydride-based ligand was obtained as an orange solid.

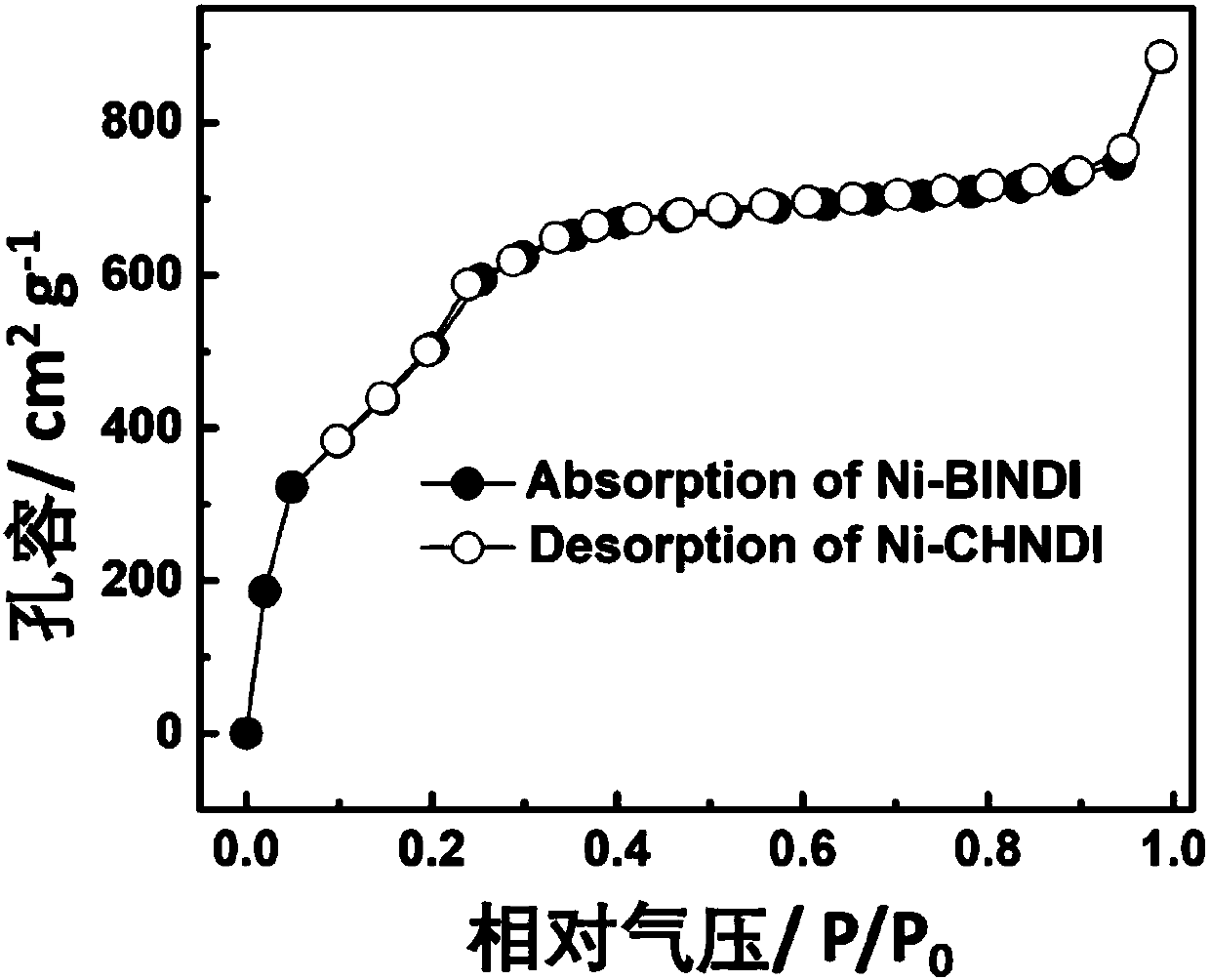

[0035] (2) Dissolve 0.6mmol of the naphthalene tetracarboxylic anhydride-based ligand obtained in step (1) in 20mL DMF to obtain solution A; simultaneously dissolve 2mmol nickel nitrate hexahydrate in 20mL ethanol to obtain solution B; pretreat the FTO glass, and Immerse in deionized water, acetone, and ethanol for 10 minutes of ultrasonic cleaning, dry, and then irradiate with ultraviolet ozone for 40 minutes, and then place them in the above solution A, ethanol, solution B and ethanol for 10 minutes each for self-assembly. The self-assembly temperature is 30 ° C. After 40 cycles and vacuum drying at 60°C for 10 h, an FTO electrode with a self-assembled Ni-MOFs film attache...

Embodiment 2

[0040] (1) Dissolve 1mmol of 1,4,5,8-naphthalene tetracarboxylic anhydride and 2mmol of 5-amino-2-hydroxybenzoic acid in 50mL of toluene and react at 130°C for 6h, then filter, wash with 1mol / L hydrochloric acid, and dry. The naphthalene tetracarboxylic anhydride-based ligand was obtained as an orange solid.

[0041](2) Dissolve 1 mmol of the naphthalene tetracarboxylic anhydride-based ligand obtained in step (1) in 20 mL of DMF to obtain solution A; at the same time, dissolve 1 mmol of nickel nitrate hexahydrate in 20 mL of ethanol to obtain solution B; pretreat the FTO glass, and then immerse Ultrasonic washing in deionized water, acetone and ethanol for 10 minutes, drying, and then ultraviolet ozone irradiation for 40 minutes, followed by placing in the above solution A, ethanol, solution B and ethanol for 30 minutes each for self-assembly, self-assembly temperature is 50 ° C, cycle 30 times, vacuum drying at 40 °C for 24 h, and the FTO electrode with self-assembled Ni-MOFs...

Embodiment 3

[0045] (1) Dissolve 2mmol 1,4,5,8-naphthalene tetracarboxylic anhydride and 2mmol 5-amino-2-hydroxybenzoic acid in 100mL toluene and react at 160°C for 10h, then filter, wash with 2mol / L hydrochloric acid, and dry. The naphthalene tetracarboxylic anhydride-based ligand was obtained as an orange solid.

[0046] (2) Dissolve 2mmol of the naphthalene tetracarboxylic anhydride-based ligand obtained in step (1) in 20mL DMF to obtain solution A; simultaneously dissolve 1.3mmol nickel nitrate hexahydrate in 20mL ethanol to obtain solution B; pretreat the FTO glass, and Immerse in deionized water, acetone and ethanol, ultrasonically wash for 10 minutes, dry, and then irradiate with ultraviolet and ozone for 40 minutes, then place in the above solution A, ethanol, solution B and ethanol for 15 minutes each for self-assembly. The self-assembly temperature is 60°C. After 50 cycles and vacuum drying at 80 °C for 8 h, an FTO electrode with a self-assembled Ni-MOFs film attached to the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com