Patents

Literature

72 results about "2-Hydroxybenzoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

• 2-HYDROXYBENZOIC ACID (noun) The noun 2-HYDROXYBENZOIC ACID has 1 sense: 1. a white crystalline substance with a bitter aftertaste; used as a fungicide or in making aspirin or dyes or perfumes. Familiarity information: 2-HYDROXYBENZOIC ACID used as a noun is very rare.

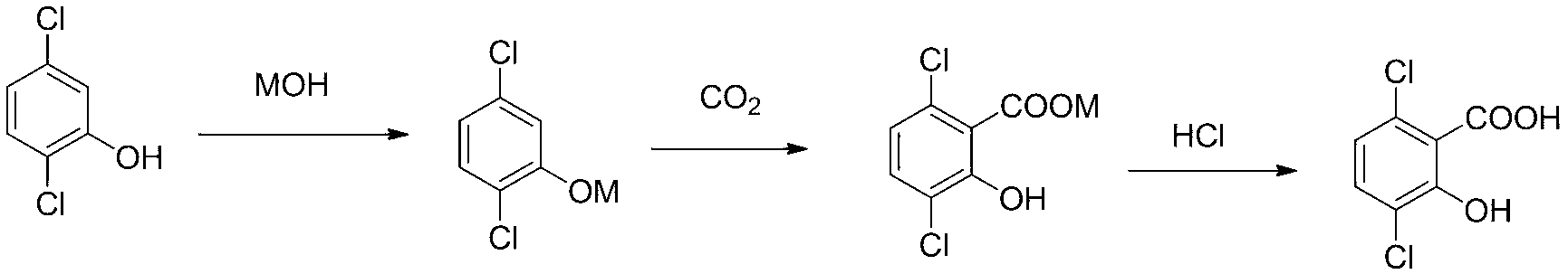

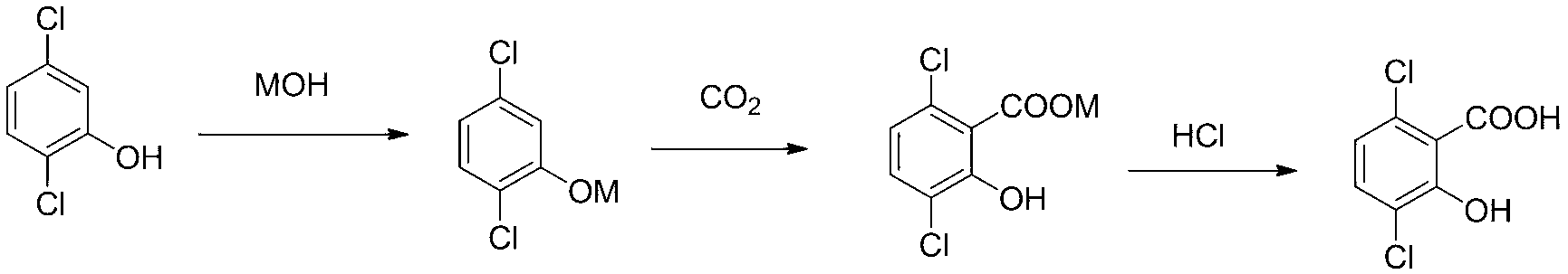

Preparation method of 3,6-dichloro-2-hydroxybenzoic acid

InactiveCN103012124AReduce manufacturing costOrganic compound preparationCarboxylic compound preparationFiltrationDistillation

The invention discloses a preparation method of 3,6-dichloro-2-hydroxybenzoic acid, which sequentially comprises the following steps: 1) salifying 2,5-dichlorophenol; 2) carboxylation: transferring the 2,5-dichlorophenate solution into a high-pressure reaction kettle, adding a cocatalyst, and introducing CO2 to carry out high-pressure carboxylation reaction to obtain the reaction product containing 3,6-dichloro-2-hydroxybenzoate, wherein the cocatalyst is composed of potassium carbonate and activated carbon; 3) refinement: after cooling the reaction product containing 3,6-dichloro-2-hydroxybenzoate obtained in the step 2) to room temperature, adding an alkali solution, regulating the pH value to 11-13, uniformly stirring, filtering to recover activated carbon, stratifying the filtrate, and taking the water phase; and adding an acid solution into the water phase, regulating the pH value to 1-3, carrying out vapor distillation to recover the 2,5-dichlorophenol, cooling to crystallize, carrying out vacuum filtration, and drying to obtain the 3,6-dichloro-2-hydroxybenzoic acid.

Owner:ZHEJIANG UNIV

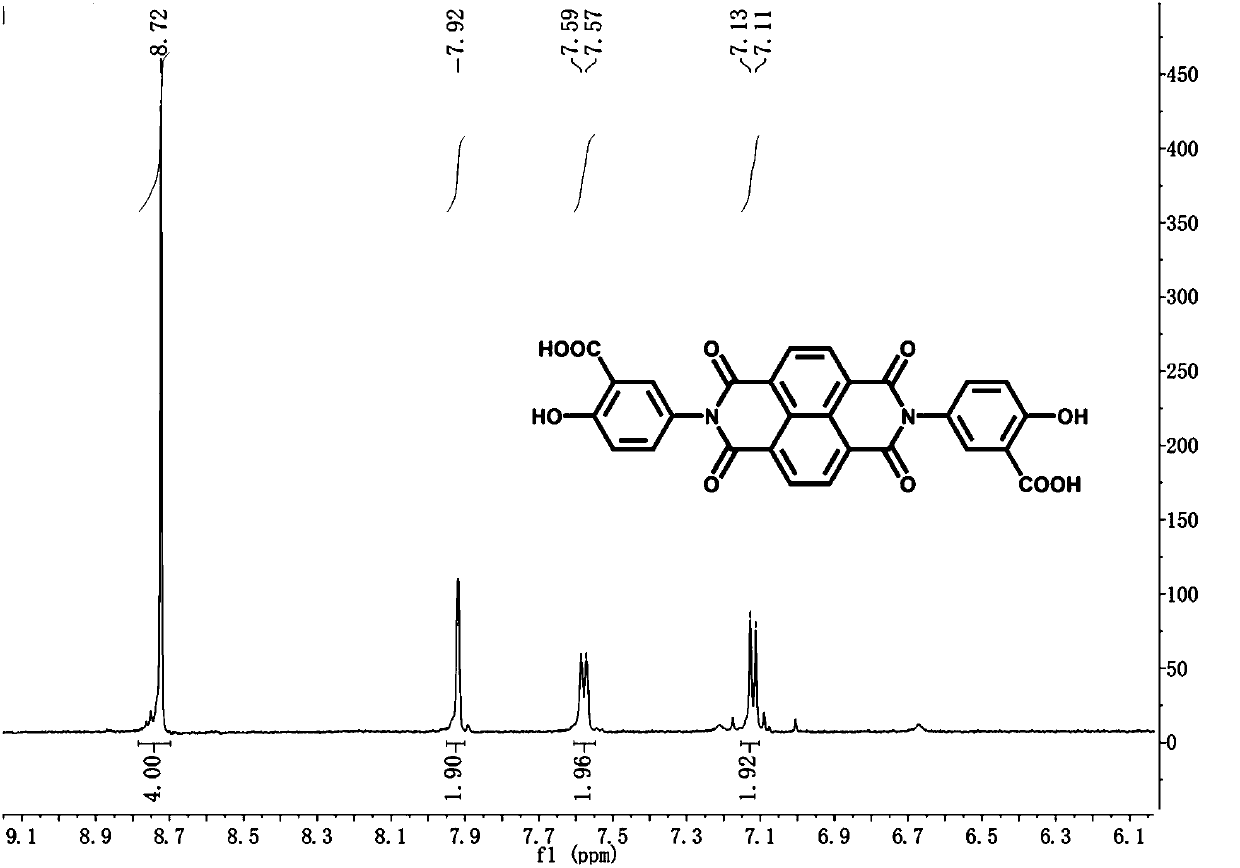

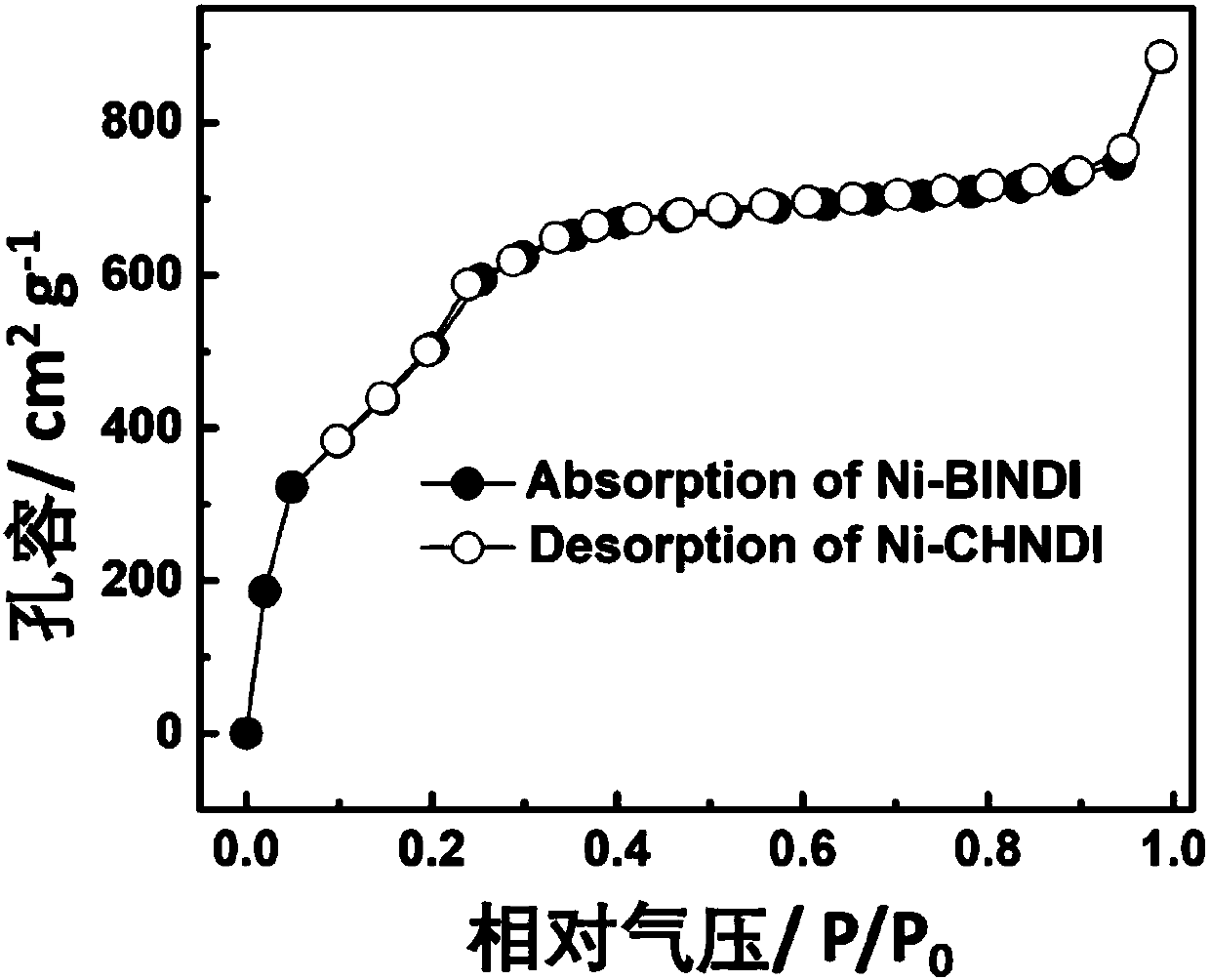

Preparation method of self-assembly Ni-MOFs electrochromic QR code device

ActiveCN108017789AImprove mechanical propertiesReduce the driving voltageTenebresent compositionsNaphthalenetetracarboxylic dianhydrideNickel salt

The invention relates to a preparation method of a self-assembly Ni-MOFs electrochromic QR code device. The method comprises the steps as follows: 1,4,5,8-naphthalenetetracarboxylic dianhydride and 5-amino-2-hydroxybenzoic acid are put in toluene, and an anhydride ligand is obtained; the ligand is dissolved in DMF and a solution A is obtained; nickel salt is dissolved in ethanol and a solution B is obtained; pretreated FTO glass is irradiated by ultraviolet ozone, the obtained FTO glass is sequentially placed in the solution A, ethanol, the solution B and ethanol for self-assembly, circulatingoperation is performed, and an FTO electrode with a Ni-MOFs film attached on the surface is obtained; a working electrode displaying QR code patterns is formed through laser etching, another FTO glass is used as a counter electrode, gel electrolyte is injected, and the device is obtained after packaging. Controllable preparation of the Ni-MOFs film is realized, the prepared QR code device can beswitched between display and hiding when positive and negative voltage is applied, and meanwhile, the device has good electrochromic performance and has wide application prospects in the fields of Internet of Things, intelligent wearable devices and the like.

Owner:DONGHUA UNIV

Chinese medicinal compound formulation for treating skin disease

InactiveCN1768841ASignificant effectReduce dosageSalicyclic acid active ingredientsAntimycoticsDiseaseCentipede

The invention provides a Chinese medicinal compound preparation for treating skin diseases, which is prepared from the raw materials including safflower, clove, pricklyash peel, atractylodes rhizome, corktree bark, broom cypress fruit, Chinese dittany bark, roor of sessile stemona, Chinese mugwort leafmulberry leaf, cortex pseudolaricis, cnidium fruit, flavescent sophora root, centipede, camphor, 2-hydroxybenzoic acid, benzene carboxylic acid, dimethyl sulfoxide and 50-60% of ethanol.

Owner:HUBEI DINGLONG PHARMA

Topical skin care formulation

ActiveUS20130156711A1Low elastic modulusReduce hardnessCosmetic preparationsHair cosmeticsPunicaSterol

Disclosed is a topical skin care composition, and method for its use, that includes 55 to 65% by weight of water, 15 to 20% by weight of a combination of 3,3,5-Trimethylcyclohexyl 2-hydroxybenzoate (homosalate), 1-(4-Methoxyphenyl)-3-(4-tert-butylphenyl)propane-1,3 -dione (avobenzone), 2-ethylhexyl 2-hydroxybenzoate (octisalate), and 2-ethylhexyl 2-cyano-3,3-diphenyl-2-propenoate (octocrylene), 3 to 4% by weight of distearlydimonium chloride, and 1 to 3% by weight of a combination of euterpe oleracea fruit extract, punica granatum sterols, caprooyl tetrapeptide-3, tocopherol or tocopherol acetate, and niacinamide, wherein the composition has a sun protection factor of at least 15 or about 15 to 20.

Owner:MARY KAY INC

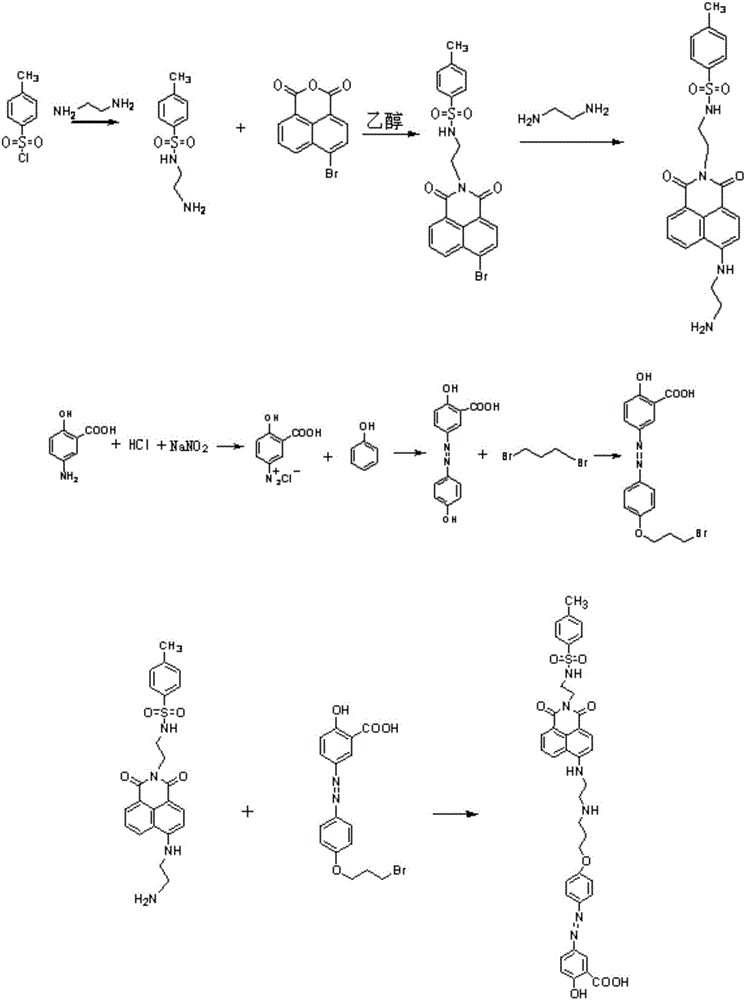

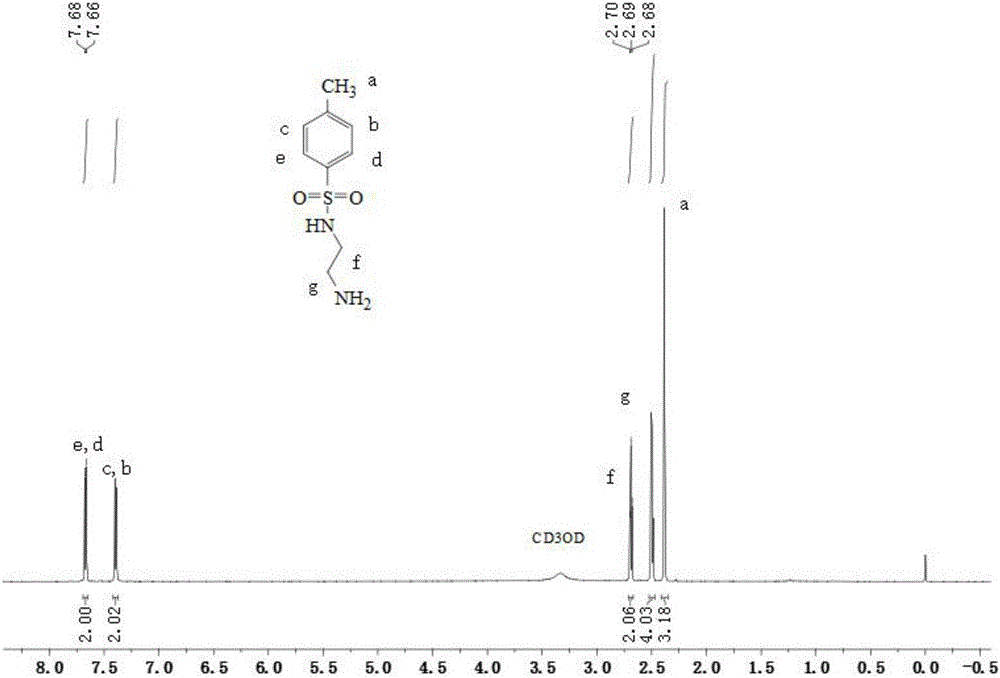

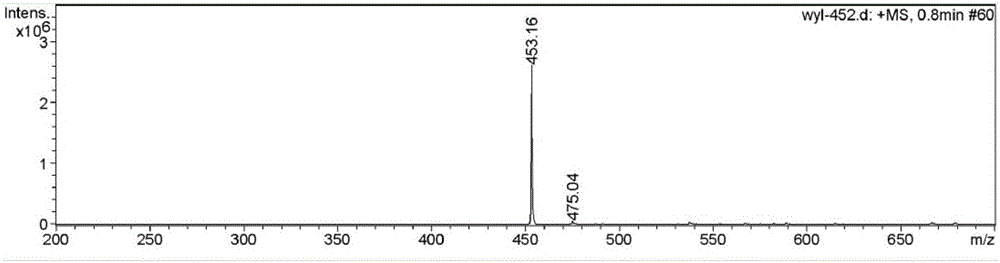

Enhanced fluorescent probe and preparation method and application thereof

ActiveCN106117139AGood water solubilityStrong absorption capacityOrganic chemistryMicrobiological testing/measurementSolubilityStructural formula

The invention belongs to the technical field of fluorescence detection materials and discloses an enhanced fluorescent probe and a preparation method and application thereof. The fluorescent probe is 5-{4-[3-(2-{2-[2-(toluene-4-sulfamine)-ethyl]-1H-benzo(de)isoquinoline-1,3(2 H)-diketone-6-amino}-ethylamino)-propoxy]-phenylazo}-2-hydroxybenzoic acid and has a molecular structural formula shown in a formula (1). The probe compound is prepared from visible light excited and emitted fluorescent chromophore naphthalimides and an azo reductase recognition group 5-aminosalicylic acid azobenzene derivative. The probe compound not only has better water solubility, but also is high in accuracy when being used for azo reductase detection, is convenient to use and can simultaneously trace release of anti-inflammatory drugs such as 5-aminosalicylic acid and provide a supplementary means for diagnosis and treatment of colitis.

Owner:SOUTH CHINA UNIV OF TECH

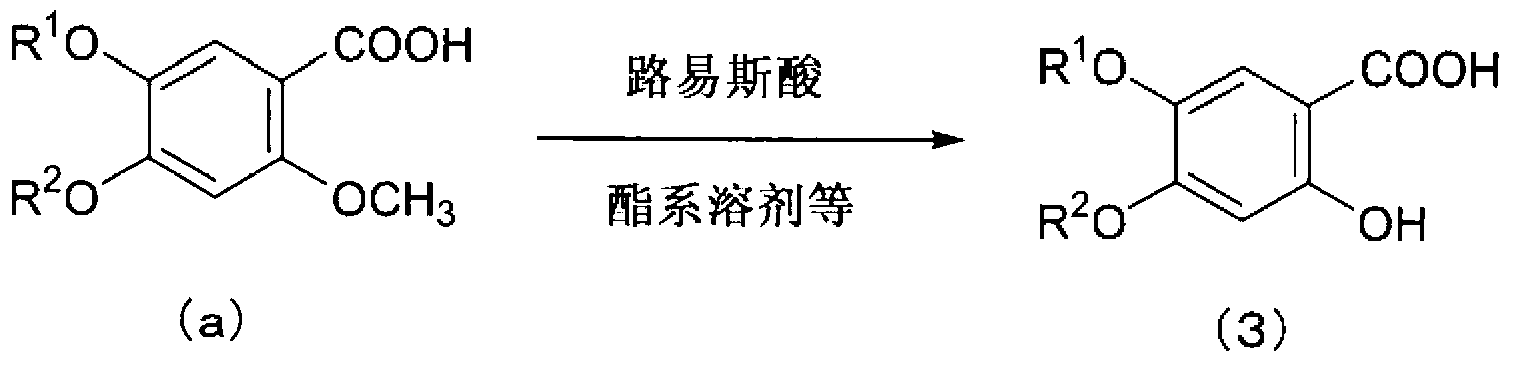

Method for producing 2-bromo-4,5-dialkoxy benzoic acid

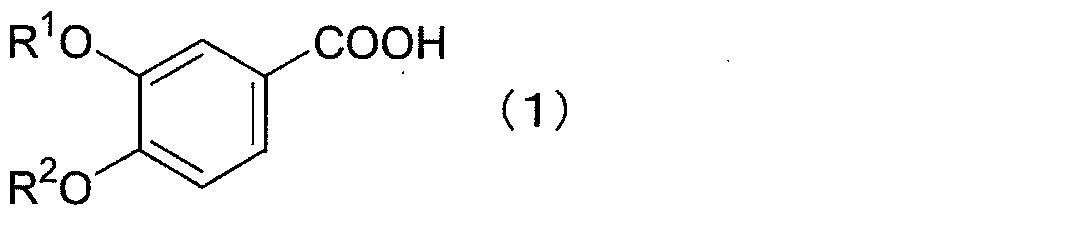

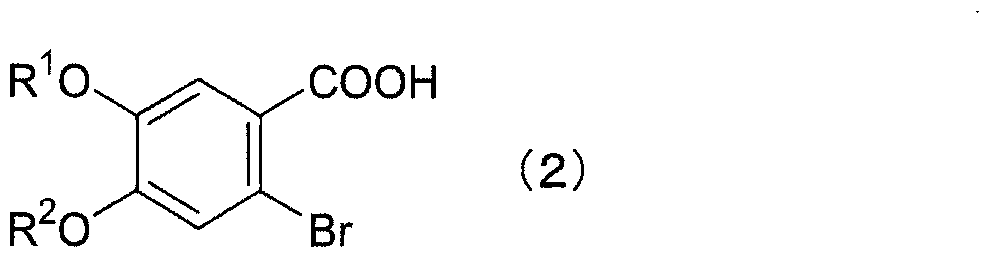

ActiveCN103237781AHigh yieldHigh purityOrganic compound preparationOrganic chemistry methodsBenzoic acidBromine

Provided is a method for effectively producing a 4,5-dialkoxy-2-hydroxybenzoic acid from an inexpensive raw material. A method for producing a 2-bromo-4,5-dialkoxybenzoic acid represented by the following formula (2): (wherein each of R1 and R2 represents a lower alkyl group), the method including causing a 3,4-dialkoxybenzoic acid represented by the following formula (1): (wherein R1 and R2 have the same meanings as defined above) to react with bromine in concentrated hydrochloric acid.

Owner:ZERIA PHARMA

Antifreeze Concentrate and Coolant Compositions and Preparation Thereof

InactiveUS20090001313A1Improve thermal stabilityOther chemical processesHeat-exchange elementsBenzoic acidOctanoic Acids

A toxicological friendly antifreeze composition having improved thermal stability is provided. In one embodiment, the antifreeze composition comprises from 5 to 80 wt. % of an aqueous freezing point depressant selected from alkali metal salts of acetates, formates, proprionates, adipiates, and succinates, and mixtures thereof; 0.1 to 10 wt. % of at least one of a 2-ethylhexanoic acid, isononanoic acid and 3,5,5-trimethylhexanoic acid; and 0.1 to 10 wt. % of at least one of octanoic acid, nonanoic acid, decanoic acid, undecanoic acid, dodecanoic acid, neodecanoic acid, benzoic acid, 2-hydroxybenzoic acid, p-terbutylbenzoic acid, and mixtures thereof. In one embodiment, the composition is employed as a concentrate in admixture with 10 to 90 wt. % water.

Owner:CHEVROU USA INC

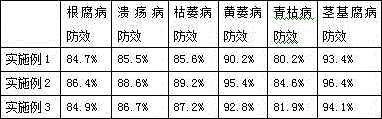

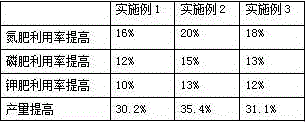

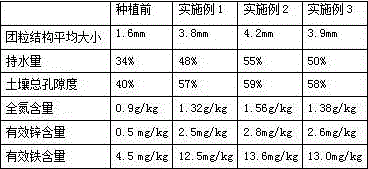

Soil disinfection and soil remediation combined technology

InactiveCN105665434AGood prevention effectSignificant improvementBiocideContaminated soil reclamationDisinfectantCanker

The invention provides soil disinfection and soil remediation combined technology. The technology includes the steps of preparation before soil disinfection, soil disinfection and soil remediation. Before soil disinfection, the ploughing depth ranges from 40 cm to 50 cm, the ridge height ranges from 20 cm to 30 cm, and the height between each film and soil in the corresponding ridge ranges from 10 cm to 20 cm. An adopted soil disinfection agent comprises the following components of dithiocarbamic acid, sodium formate, nitrite 2-chloroisobutyl, borax, cyclodextrin, laminarin and phthalimide. An adopted soil remediation agent comprises the following components of microorganism bacterium powder, sodium alginate, 2-hydroxybenzoic acid-5-sodium sulfonate, beta-cyclodextrine, sodium caseinate, medical stone powder, EDTA-iron, corn protein peptide, polyglutamic acid, polyacrylamide and cortex pseudolaricis powder. The soil disinfection and soil remediation combined technology has remarkable effects on the root rot, canker, wilt, verticillium wilt, bacterial wilt and basal rot of plants and meanwhile has remarkable improvement effects on the soil properties.

Owner:WEIFANG XINYOUJI SOIL DISINFECTION PROFESSIONAL SERVICES COOP

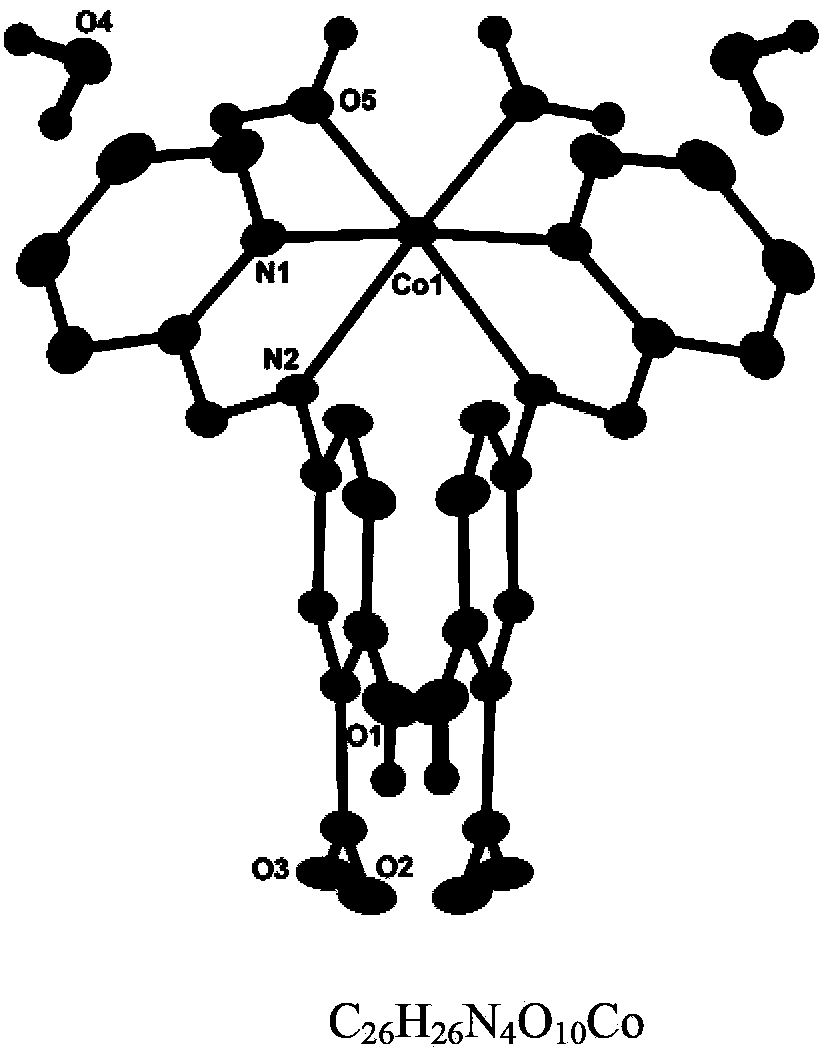

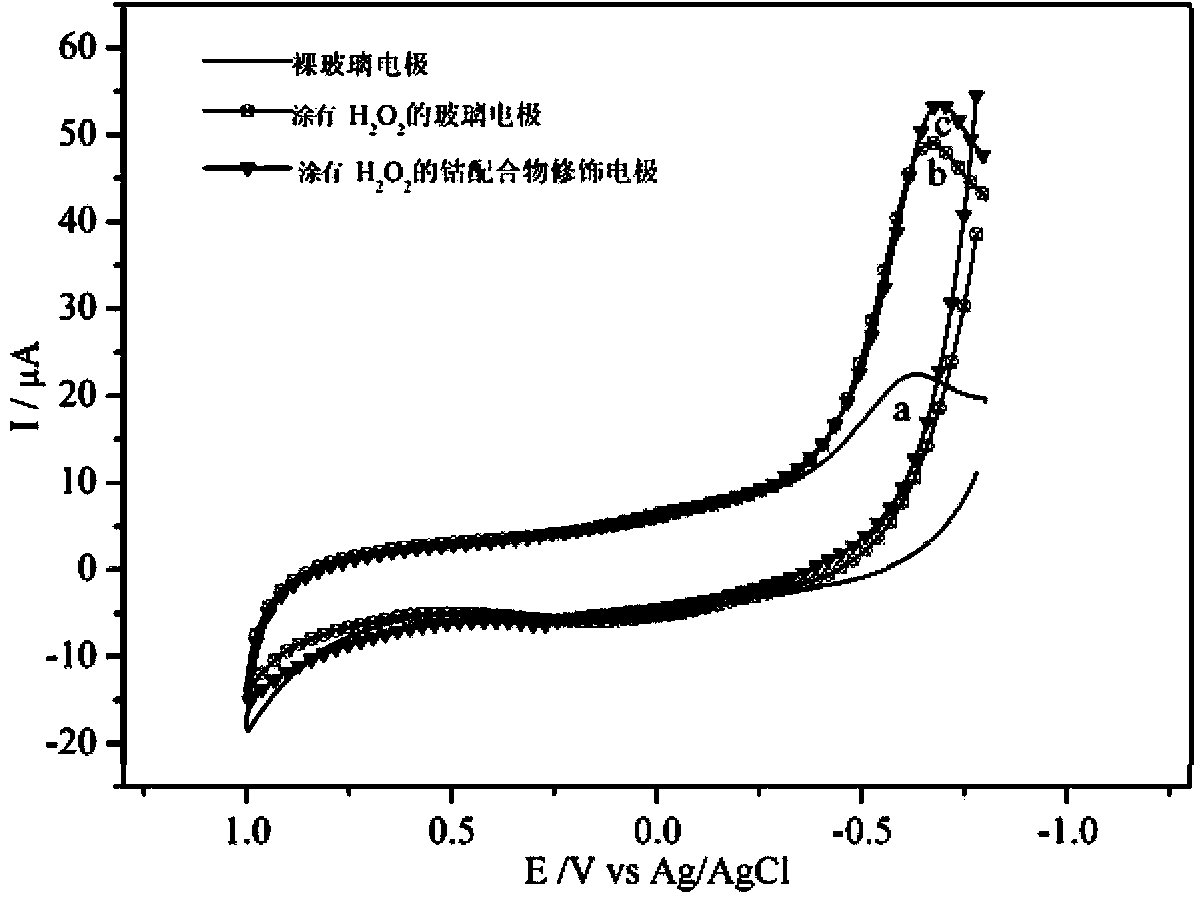

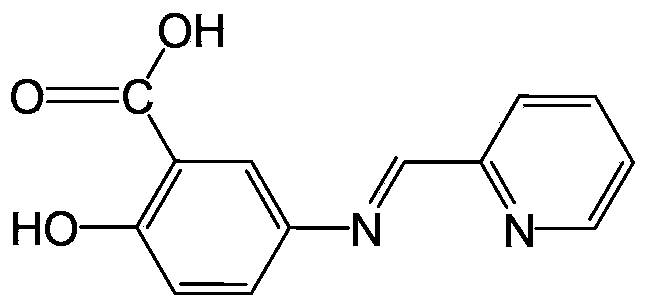

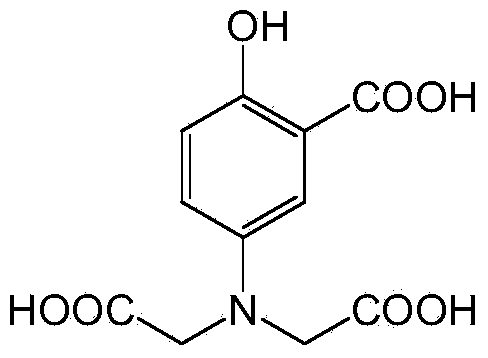

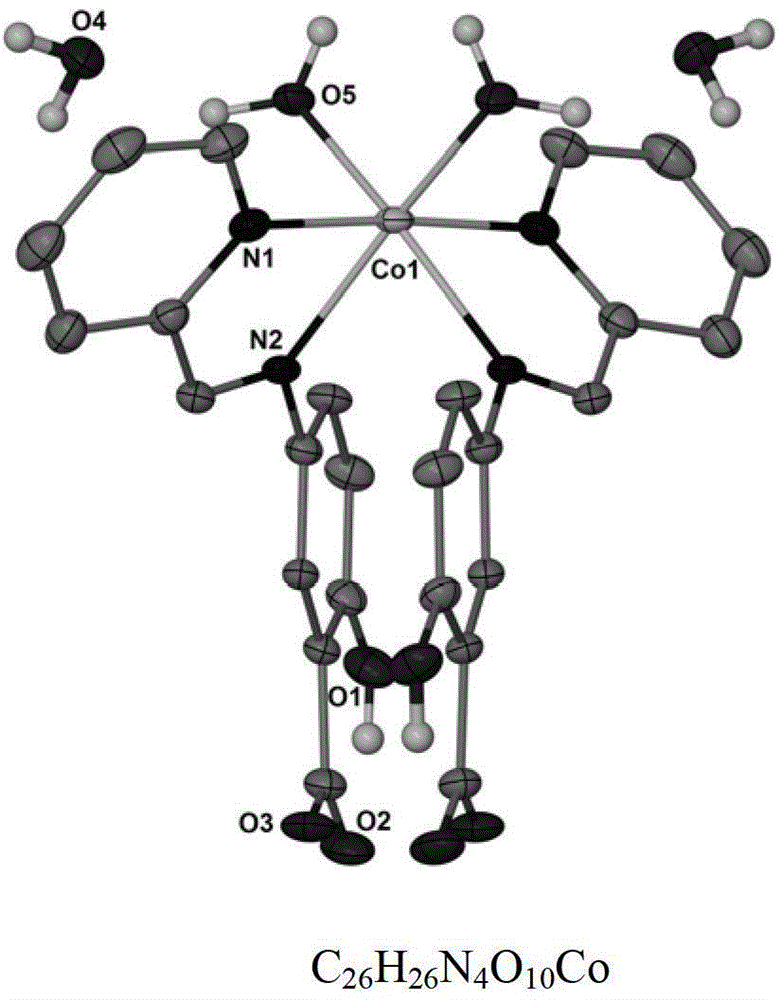

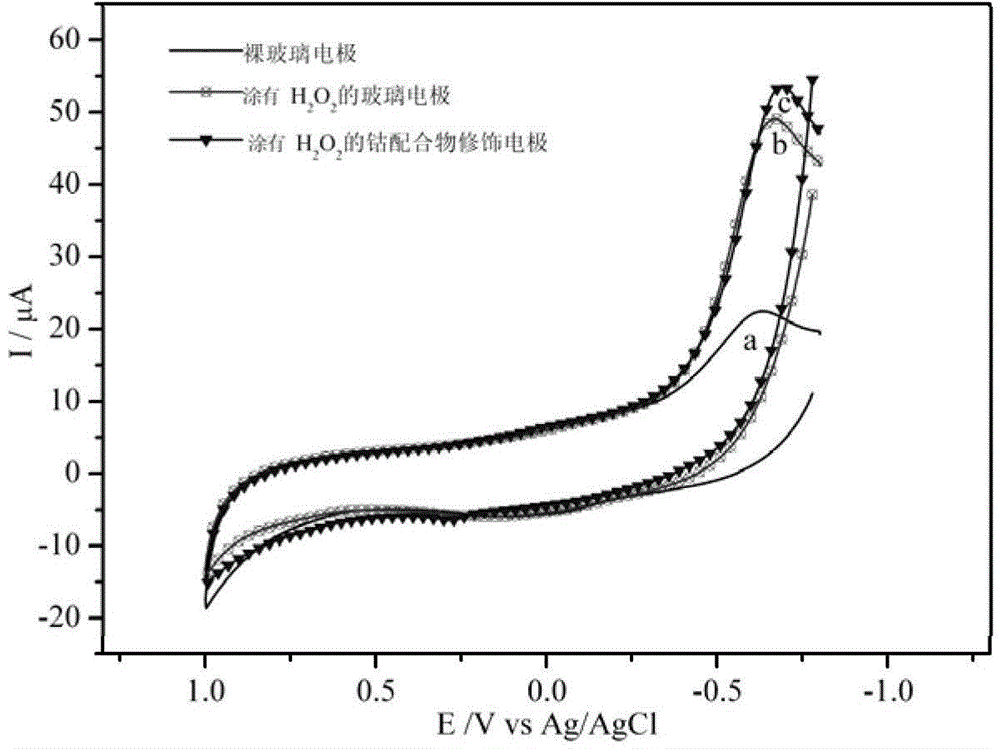

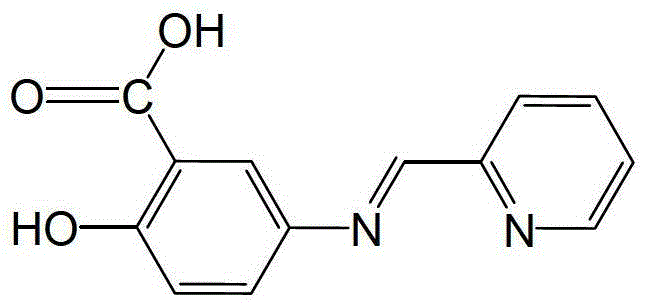

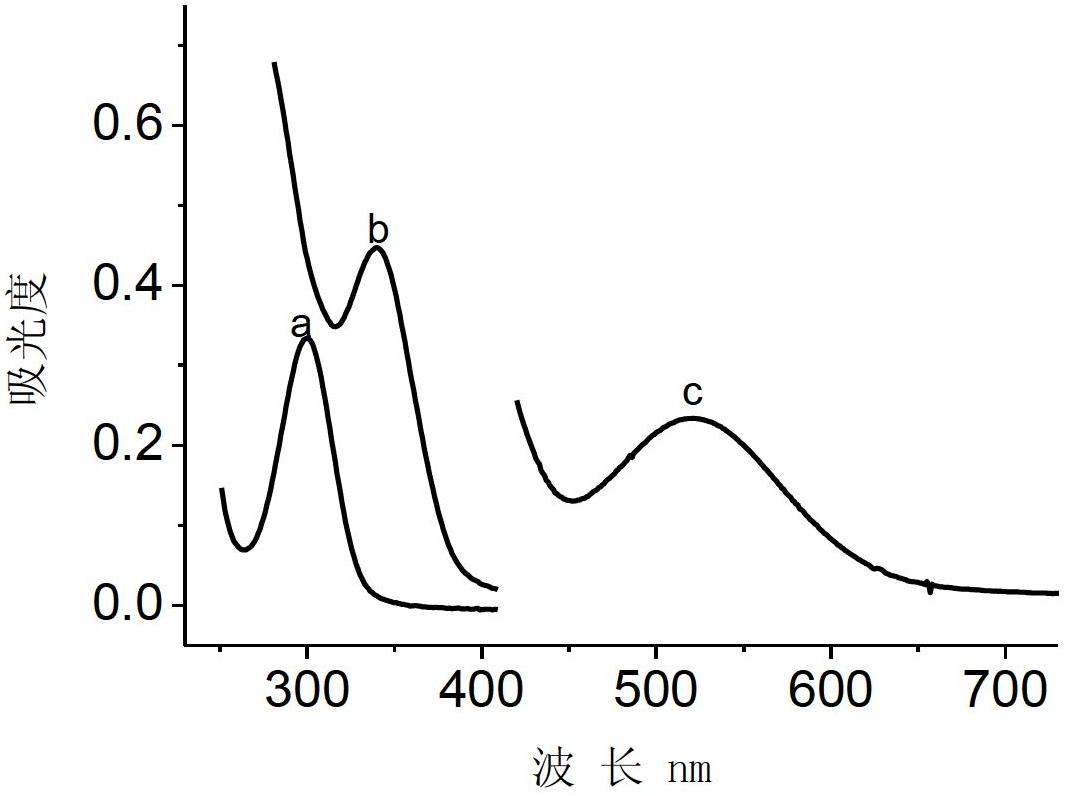

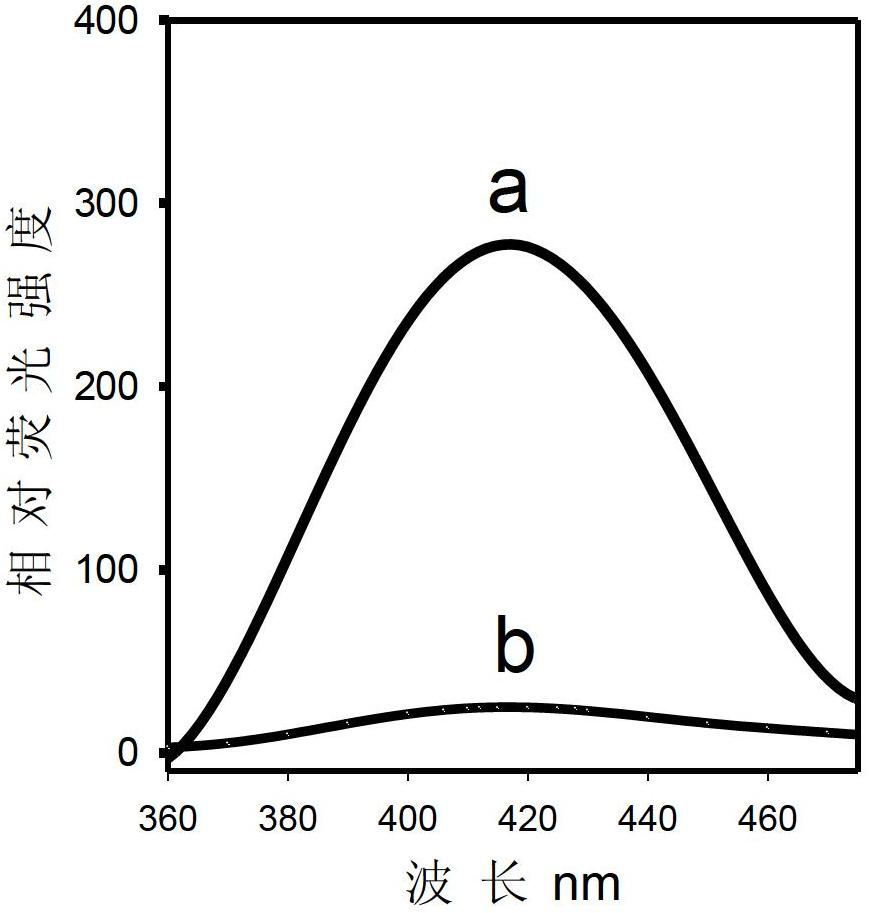

Cobalt complex having electrocatalytic activity on hydrogen peroxide

InactiveCN103467367AAccurate spatial structureHigh electrochemical catalytic activityOrganic chemistryAminosalicylic acid2-Hydroxybenzoic acid

The invention discloses a cobalt complex and a preparation method thereof, and the cobalt complex is characterized by having good electrocatalytic activity on hydrogen peroxide, the molecular formula of the cobalt complex is C26H26N4O10Co, the crystal system is orthorhombic, the space group is Pbcn, the cell parameters alpha, gamma and beta satisfy: a=15.928Angstrom, b=10.602Angstrom, c=15.596Angstrom, alpha is equal to gamma, is equal to beta and is equal to 90 degrees. The cobalt complex prepared in the invention is obtained by a mixing reaction of a cobalt salt and a derivative of 5-aminosalicylic acid, namely, 5-((2-pyridyl) methylene amino)-2-hydroxybenzoic acid according to a certain proportion, the cobalt complex has a specific spatial structure and an accurate molecular formula, the synthesis steps are simple, the yield can reach 45-70%, and the cobalt complex has good electrocatalytic activity, thereby being capable of being used as an electrocatalytic active material having a potential application prospect.

Owner:NINGBO UNIV

Synthetic method for 3,6-dichloro-2-hydroxybenzoic acid

InactiveCN103012123AReduce manufacturing costLower reaction costOrganic compound preparationCarboxylic compound preparationFiltrationDistillation

The invention discloses a synthetic method for 3,6-dichloro-2-hydroxybenzoic acid, which sequentially comprises the following steps: 1) salifying 2,5-dichlorophenol, 2) performing carboxylation, and 3) performing refinement, wherein according to Step 2), a 2,5-dichlorophenol saline solution is transferred into a high-pressure reactor, a catalyst is added, CO2 is supplied for high-pressure carboxylation reaction, a reaction product containing 3,6-dichloro-2-hydroxybenzoic acid salt is obtained, and the catalyst is potassium chloride; and according to Step 3), an alkaline solution is added after the reaction product is cooled to a room temperature, pH is adjusted to 11-13, an aqueous phase is obtained after layering, an acid solution is added to the aqueous phase, the pH is adjusted to 1-3, and after vapor distillation is performed and 2,5-dichlorophenol is recovered, suction filtration and drying are performed, and 3,6-dichloro-2-hydroxybenzoic acid is obtained. 3,6-dichloro-2-hydroxybenzoic acid synthesized with the method has the characteristics of low cost and higher yield.

Owner:ZHEJIANG UNIV

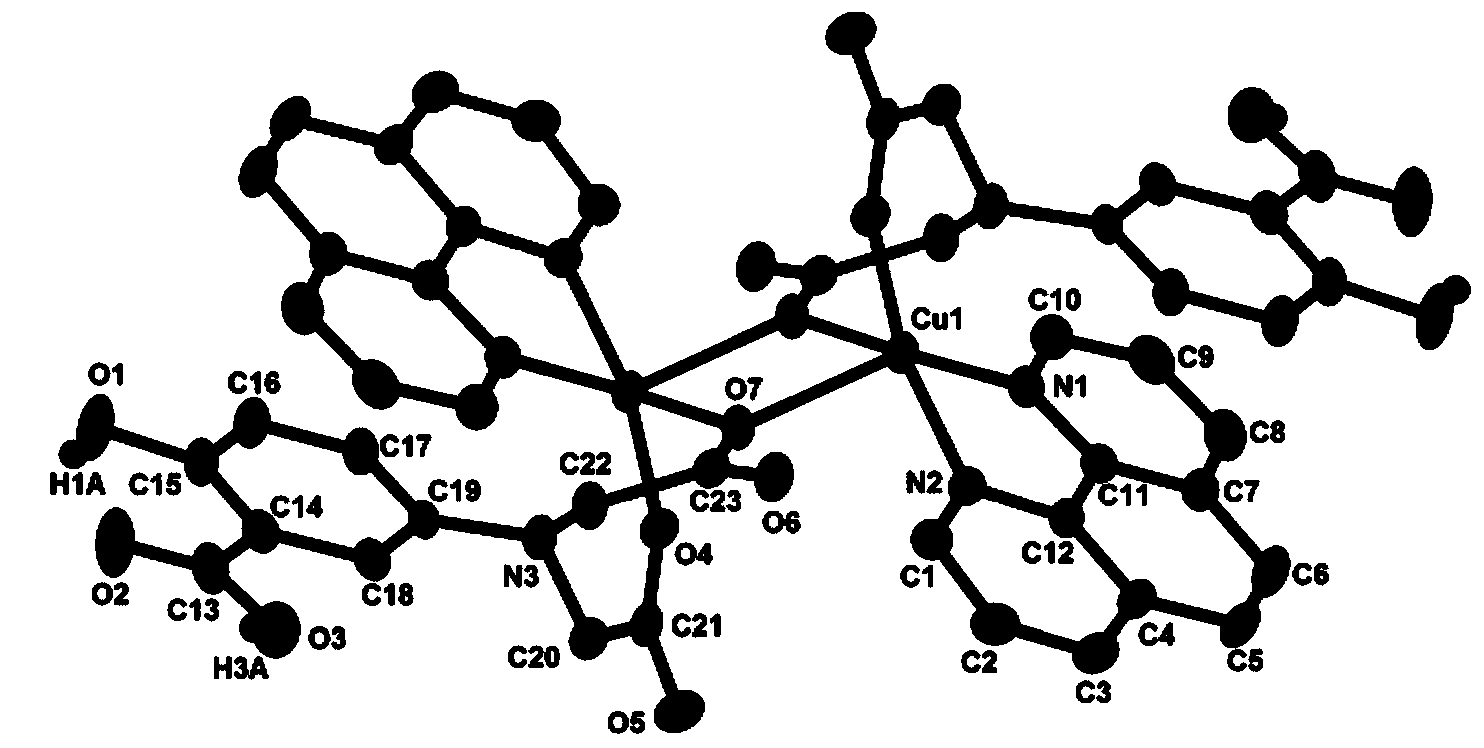

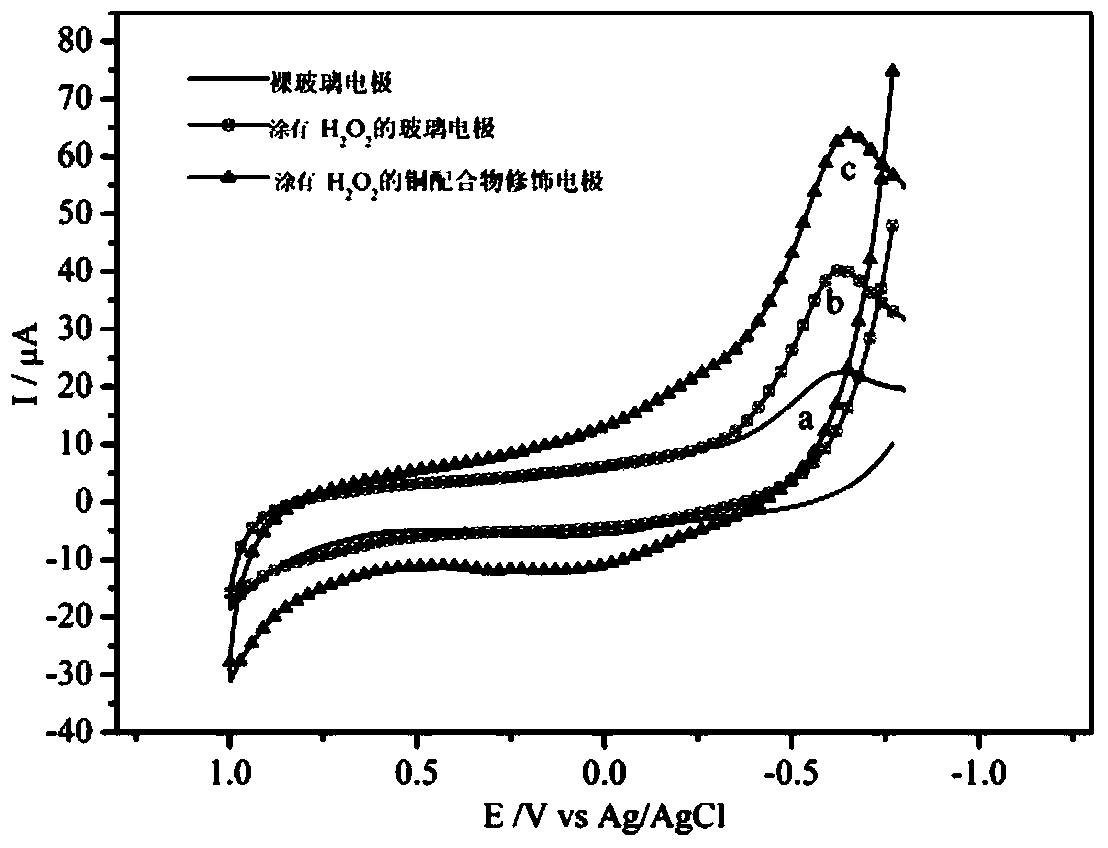

Copper complex having electrocatalytic activity on hydrogen peroxide and preparation method thereof

ActiveCN103467498AAccurate spatial structureHigh electrochemical catalytic activityCopper organic compoundsCrystal systemSpatial structure

The invention discloses a copper complex and a preparation method thereof, and the copper complex is characterized by having good electrocatalytic activity on hydrogen peroxide, the molecular formula of the copper complex is C46H34N6O14Cu2, the crystal system is clinorhomboidal, the space group is P-1, the cell parameters are as follows: alpha is equal to 99.90 degrees, beta is equal to 101.2 degrees and gamma is equal to 93.69 degrees. The copper complex is prepared from a mixing reaction of a copper salt, 5-(di(carboxymethyl) amino)-2-hydroxybenzoic acid and 1,10-phenanthroline according to a certain proportion, the copper complex has a specific spatial structure and an accurate molecular formula, the synthesis steps are simple, and the yield can reach 30-70%. The copper complex prepared in the invention has good electrocatalytic activity, thereby having a broad application prospect of being used as a potential electrocatalytic active material.

Owner:菏泽建数智能科技有限公司

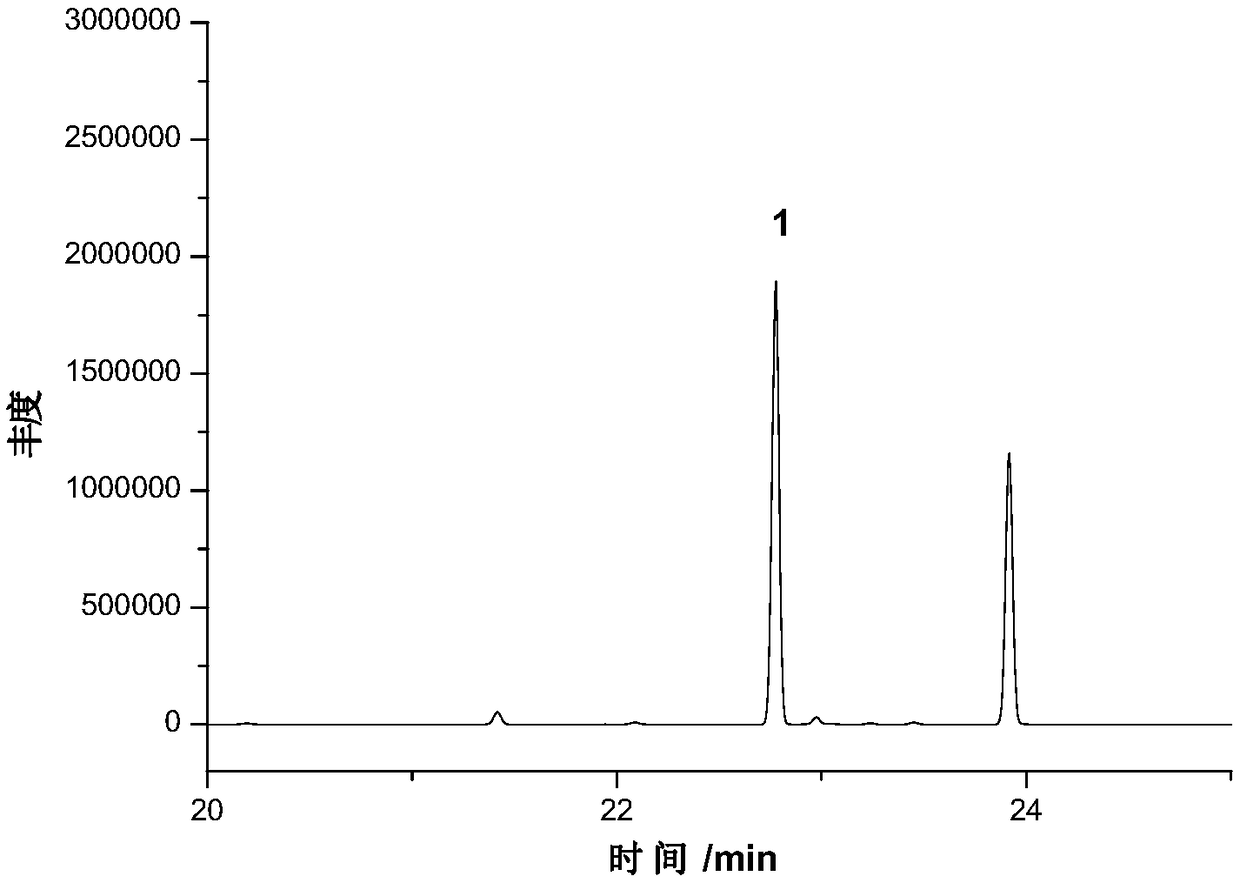

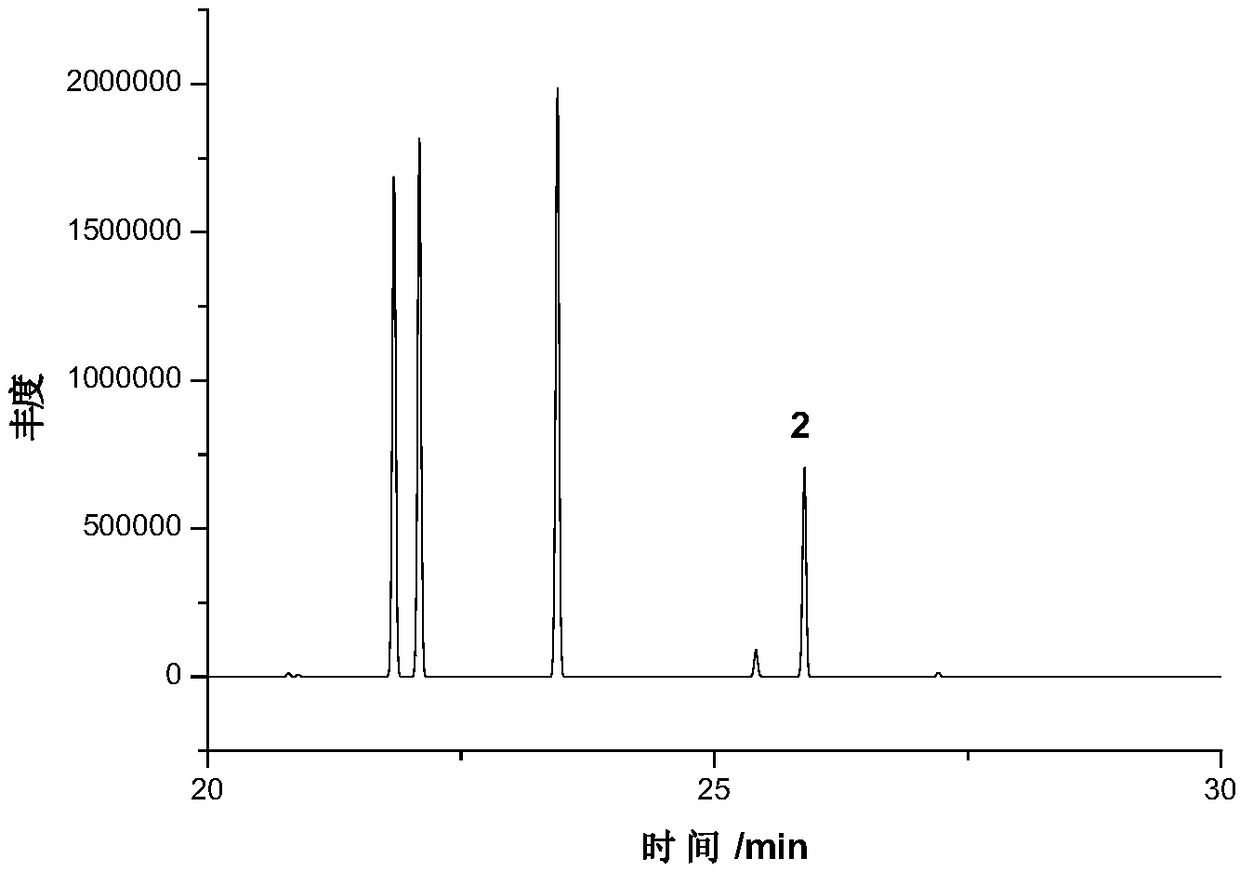

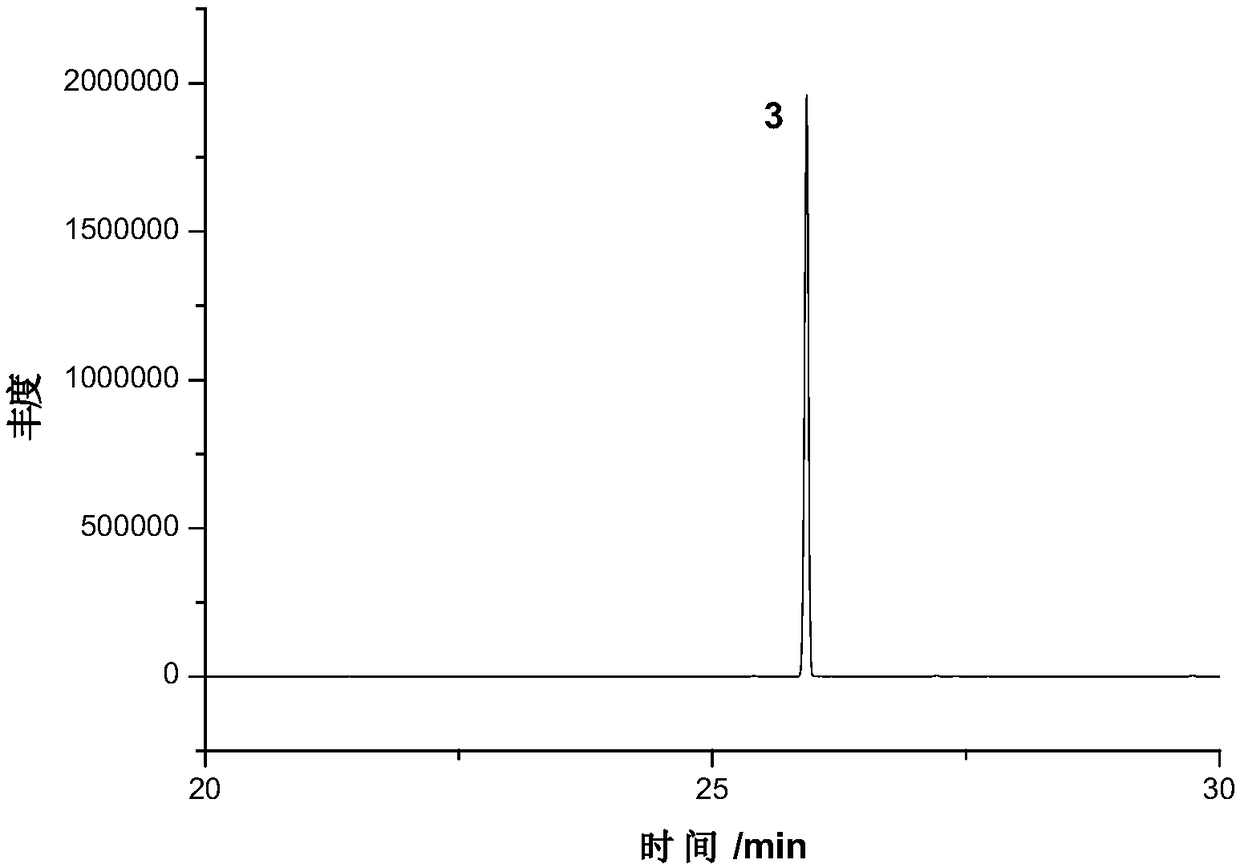

Measurement method for non-fat organic acids in tobacco and tobacco product

The invention relates to a measurement method for non-fat organic acids in tobacco and a tobacco product and belongs to the technical field of analysis of acidic components in the tobacco and the tobacco product. The measurement method provided by the invention comprises the steps of extracting a to-be-measured sample, and taking extract liquid for derivative reaction to obtain to-be-measured liquid; taking the to-be-liquid, and carrying out gas chromatography-tandem mass spectrometry, wherein a gas chromatography condition comprises the following heating program of keeping 40-60 degrees centigrade for 1-3 min, heating to 140-160 degrees according to 3-10 degrees centigrade / min, heating to 190-210 degrees centigrade according to 5-10 degrees centigrade / min, heating to 270-290 degrees centigrade according to 20-30 degrees centigrade / min, and keeping warm for 15-25 min. According to the measurement method provided by the invention, various non-fat organic acids can be effectively separated, sensitivity is high, and the measurement method can be used for measuring content of the organic acids such as 3-hydroxypropionic acid, m-toluic acid, 4-oxononanoic acid, 2-hydroxybenzoic acid andcinnamic acid.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

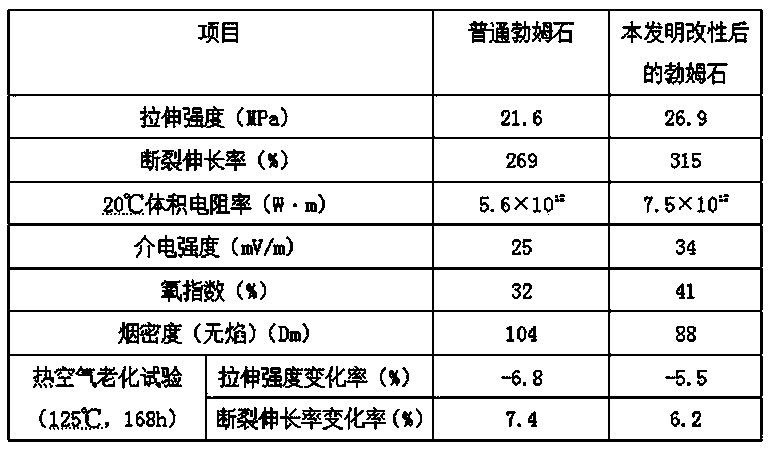

Modified boehmite for heatproof flame retardant cable materials and preparation method thereof

InactiveCN104163939AAcid resistantFlame retardantPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPhosphateBenzoic acid hydrazide

The invention discloses modified boehmite for heatproof flame retardant cable materials and a preparation method thereof, and the modified boehmite is made from the following raw materials by weight: 100 parts of boehmite, 15-25 parts of expanded graphite powder, 3-6 parts of triglycidyl isocyanurate, 20-30 parts of nano black stone, 10-15 parts of ceramic beads, 10-15 parts of butyl benzyl phthalate, 2-3 parts of 4-amion-2,2,6,6-tetramentylniperidine, 5-10 parts of phenyl isopropylphenyl phosphate, 1.5-2.5 parts of 2-hydroxy magnesium benzoate, 2-3 parts of p-hydroxy benzoic acid hydrazide, 4-6 parts of behenamide, 0.5-1.5 parts of resorcinol monobenzoate, 1-2 parts of dilauryl thiodipropionate and 3-5 parts of an auxiliary. The modified boehmite has the advantages of high in acid resistant, flame retardant and smoke suppression functions, good in filling effect, free of secondary pollution after combustion, low cost, and the like, not only can improve the flame retardant properties of the cable materials, but also can improve the heat resistance, corrosion resistance, dielectric property and mechanical strength of the cable materials.

Owner:滁州市富力克斯电线电缆有限公司

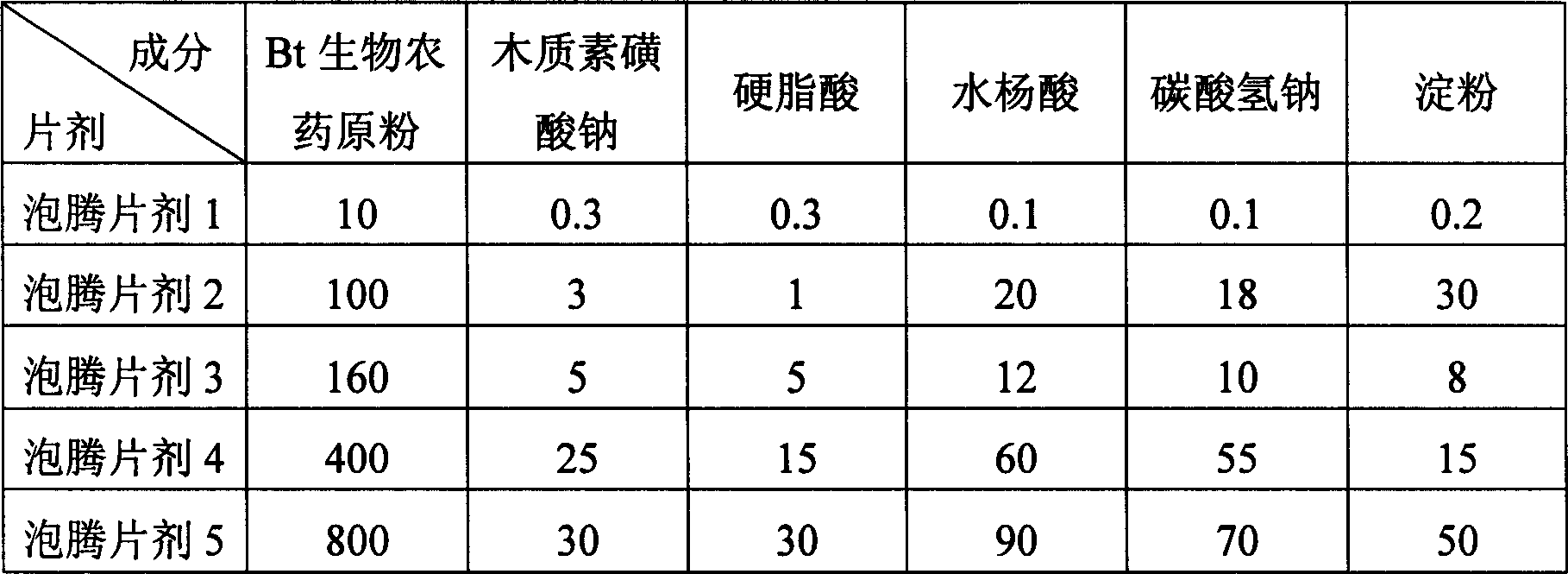

Bacillus thuringiensis biological pesticide effervescence tablet

Disclosed is a Bacillus thuringiensis (Bt) biological pesticide effervescence tablet, which comprises Bt biological pesticide raw powder and findings including wetting agent, emulsifying agent, crumbling agent, and binding agent. The constituents include Bt biological pesticide raw powder, lignin sulfonic acidic sodium, stearic acid, 2-hydroxybenzoic acid, sodium hydrogen carbonate, and starch. The invention has the advantages of less contamination, easy transportation, long keeping time and easiness in application.

Owner:UNIV OF SCI & TECH BEIJING

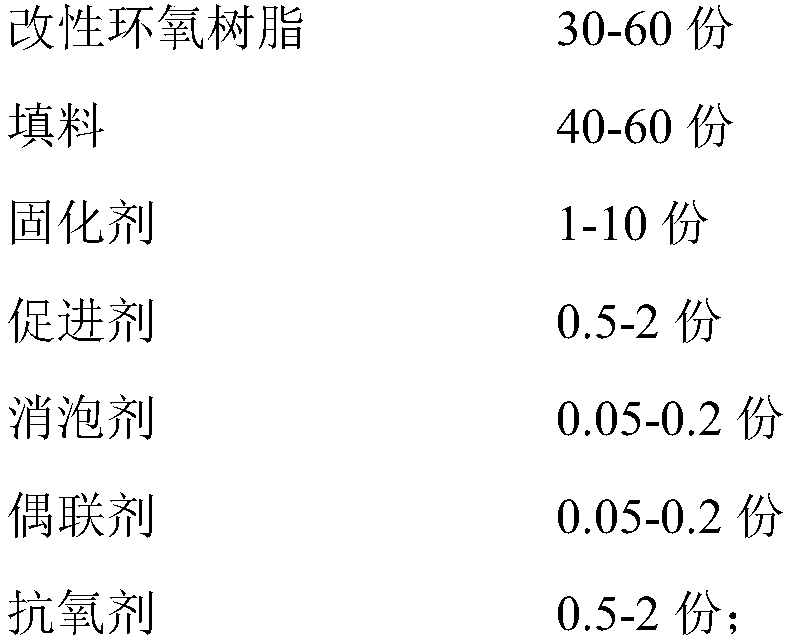

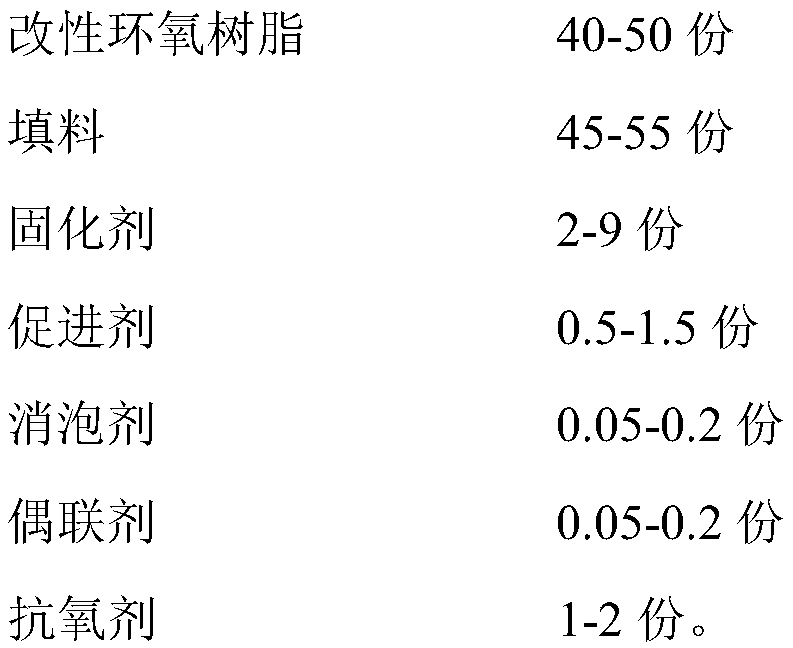

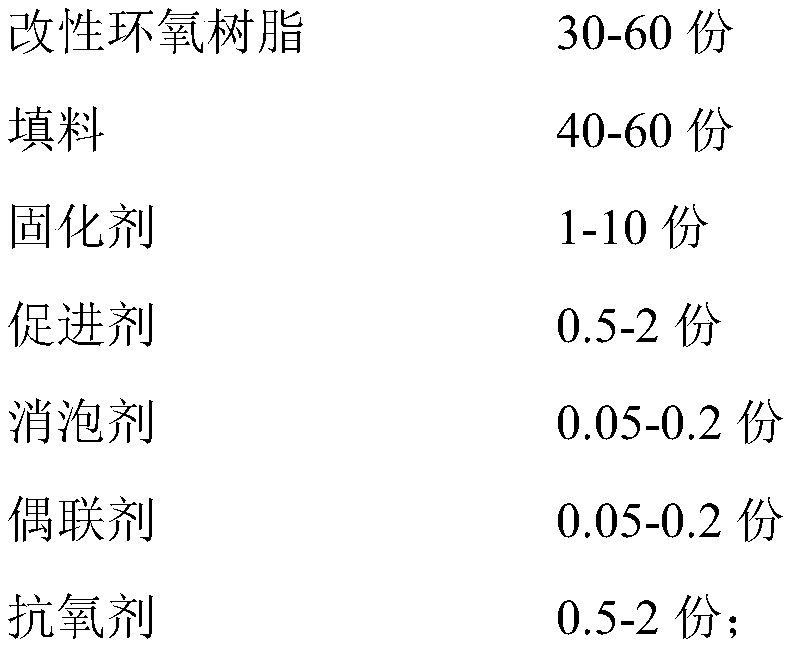

Outer plugging resin and preparation method thereof

The invention provides an outer plugging resin. The outer plugging resin comprises, by weight, 30 to 60 parts of modified epoxy resin, 40 to 60 parts of a filler, 1 to 10 parts of a curing agent, 0.5to 2 parts of an accelerator, 0.05 to 0.2 parts of a defoaming agent, 0.05 to 0.2 parts of a coupling agent and 0.5 to 2 parts of an antioxidant. The modified epoxy resin is 4-benzamido-2-hydroxybenzoic acid-modified tetrabromobisphenol A type epoxy resin.

Owner:广东科鼎新材料股份有限公司

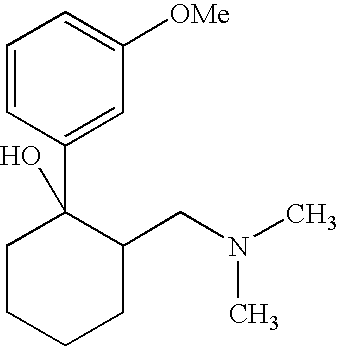

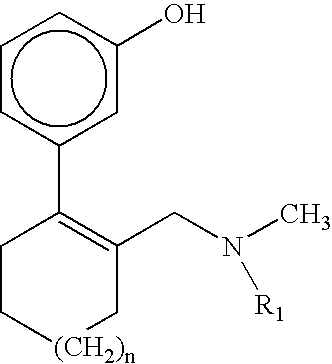

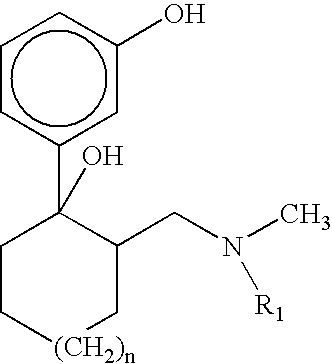

Esters derived from (RR,SS)-2-hydroxybenzoate of 3-(2-dimethylaminomethyl-1-hydroxycyclohexyl)phenyl

New esters derived from (RR, SS)-3-(2-dimethylaminomethyl-1-hydroxycyclohexyl)phenyl 2-hydroxybenzoate, analog to Tramadol, a process for obtaining them and the use of these compounds for the production of a medicament with analgesic properties.These new products of general formula (I) exhibit an analgesic activity higher than that of tramadol.

Owner:LAB VITA

Low-nitric acid chemical deburring liquid for burr removal of iron pillar shaped helical spring

The invention relates to a hyponitric chemical deburring liquid and a deburring method for an iron-based cylindrical coil spring. The deburring liquid is prepared by the following compositions according to per liter liquid 200 to 220 milliliters of hydrochloric acid, 20 to 30 milliliters of nitric acid, 15 to 20 micrograms of 2-hydroxybenzoic acid, 0.5 to 1.0 gram of gelatine, 1 to 2 grams of polyethyleneglycol, 2 to 3 grams of nonyl phenol polyethenoxy ether, the balance being water. The chemical deburring method comprises the following steps of: a). preparation of deburring liquid; b). deburring; c). cold-water washing; d). neutralizing treatment; e). cold-water washing; f). hot-water washing; g). drying; and h). immersion of rust-preventative oil. The deburring liquid has the advantages that: the content of the nitric acid in the deburring liquid is very low, thereby nitrogen oxide generated is very limited, consequently the deburring liquid has low pollution and is environment-friendly. Simultaneously, the deburring production process has simple operation, short working procedure time, and high burr removal rate, and is suitable for mass production of the cylindrical coil springs which have complex shapes and are difficult to perform mechanical deburring; and the surface finish quality of parts after deburring is high. Moreover, the raw materials of the deburring liquid are low in price and the energy consumption of the deburring treatment is low, thereby the method is favorable for saving the resources and reducing the production cost.

Owner:JIANGSU UNIV +1

Cobalt complex having electrocatalytic activity on hydrogen peroxide

InactiveCN103467367BAccurate spatial structureHigh electrochemical catalytic activityOrganic chemistryCrystal systemSpace group

The invention discloses a cobalt complex and a preparation method thereof, and the cobalt complex is characterized by having good electrocatalytic activity on hydrogen peroxide, the molecular formula of the cobalt complex is C26H26N4O10Co, the crystal system is orthorhombic, the space group is Pbcn, the cell parameters alpha, gamma and beta satisfy: a=15.928Angstrom, b=10.602Angstrom, c=15.596Angstrom, alpha is equal to gamma, is equal to beta and is equal to 90 degrees. The cobalt complex prepared in the invention is obtained by a mixing reaction of a cobalt salt and a derivative of 5-aminosalicylic acid, namely, 5-((2-pyridyl) methylene amino)-2-hydroxybenzoic acid according to a certain proportion, the cobalt complex has a specific spatial structure and an accurate molecular formula, the synthesis steps are simple, the yield can reach 45-70%, and the cobalt complex has good electrocatalytic activity, thereby being capable of being used as an electrocatalytic active material having a potential application prospect.

Owner:NINGBO UNIV

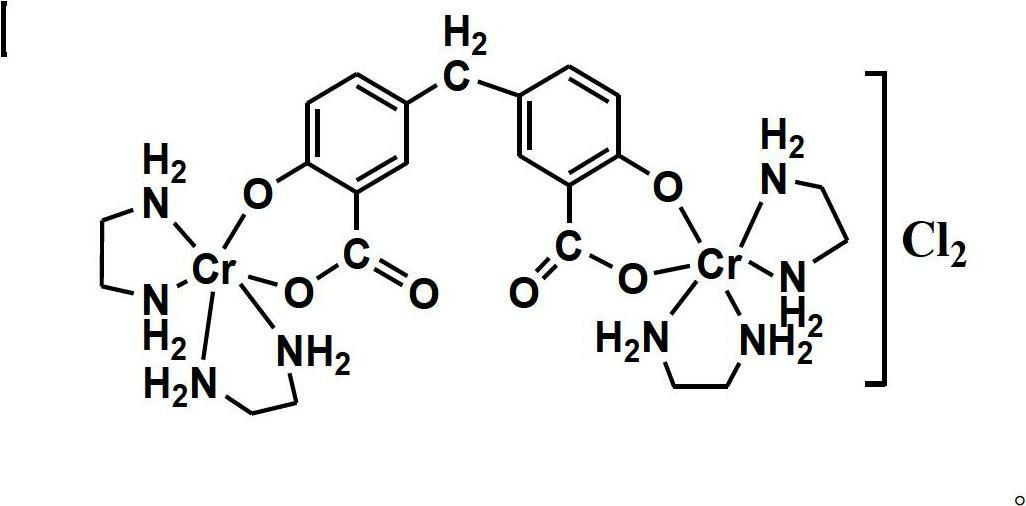

Cr (III) chelate, and preparation method and application thereof

InactiveCN102659844AIncrease profitGood water solubilityMetabolism disorderGroup 6/16 element organic compoundsSolubilityReflux

The invention provides a Cr (III) chelate, and a preparation method and application thereof. The preparation method for the chelate comprises the following steps: preparing 5,5-methylene di(2-hydroxybenzoic acid); putting Cr (III) Cl3.6H2O and the 5,5-methylene di(2-hydroxybenzoic acid) into a reactor, dissolving by using organic alcohol, adding zinc particles, dripping ethanediamine in a reflux state, and continuously reacting for 15 to 60 minutes, wherein 1.85g of 5,5-methylene di(2-hydroxybenzoic acid), 0.1 to 1g of zinc particles, 10 to 30ml of organic alcohol and 0.5 to 1g of ethanediamine are added into each 1g of Cr(III)Cl3.6H2O; and cooling and filtering a reaction liquid to obtain a target product. The chelate is high in water solubility, has a sustained release function, is easily absorbed and can be applied to preparing weight-reducing medicines.

Owner:SHANXI UNIV

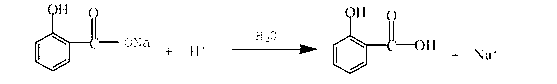

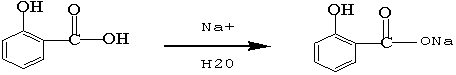

Recycling method of 2-hydroxybenzoic acid-2-ethyl caprolactone production liquid waste

ActiveCN103288633AReduce consumptionReduce processing costsOrganic compound preparationCarboxylic acid esters preparationLiquid wasteSalicylic acid

The invention provides a recycling method of a 2-hydroxybenzoic acid-2-ethyl caprolactone production liquid waste. The method comprises: adjusting the pH of wastewater produced in an esterification synthesis procedure to 2 through hydrochloric acid with mass concentration of 30%, fully stirring for half an hour, separating out white crystals from the wastewater, and centrifugally dewatering to obtain salicylic acid crystals, wherein the purity of the crystals is not smaller than 98% and the water content is not larger than 18%; the obtained salicylic acid crystals can be used as production raw materials of 2-hydroxybenzoic acid-2-ethyl caprolactone, and the salicylic acid crystals are directly applied in the esterification synthesis of OS104 without being dried; and the consumption of the salicylic acid raw material is reduced, the production cost is lowered, and meanwhile, the wastewater treatment cost is reduced.

Owner:宜都市华阳化工有限责任公司

Mildew resistant medicament and application thereof

InactiveCN1799355ASolve the permanent mildew problemSolve the mildew problemBiocideAnimal repellantsMildewPara-nitrobenzaldehyde

The invention provides a medical agent for preventing the information-recording material from rotting, used for preventing various disk and mag tape from rotting. The long-acting mildew-resistant medicinal agent is comprised with the following raw material with the weight proportion being: m-nitrobenzaldehyde: 10-70%, ª‡-benzalacet aldehyde bromide: 10-70%, 2-hydroxybenzoic acid: 5-40%, geoceric acid: 0.5-20%. The medicine can release the mildew-resistant medical agent of many times as much as that of lowest bacteria inhibitor, possesses high effective killing or inhibiting ability for the common fungus in air, and can preventing the information recording material such as various disk, mag tape and compact disk from rotting.

Owner:华中科技大学同济医学院

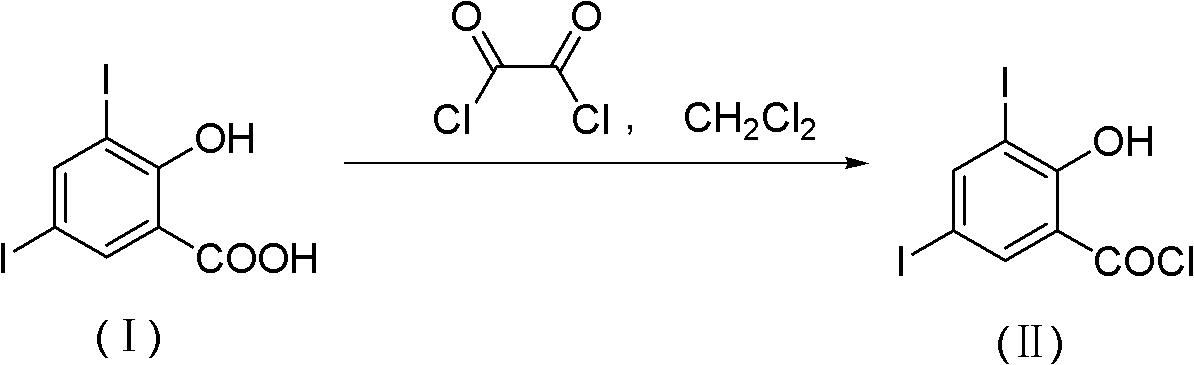

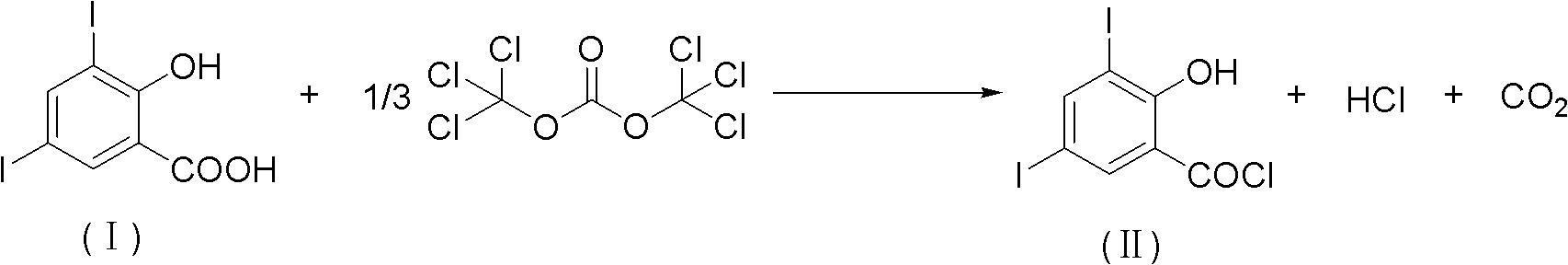

Method for chemically synthesizing 3,5-diio-2-hydroxybenzene formyl chloride

InactiveCN102206152AHigh yieldHigh purityOrganic compound preparationCarboxylic compound preparationChemical synthesisOrganic solvent

The invention discloses a method for chemically synthesizing 3,5-diio-2-hydroxybenzene formyl chloride. The method comprises the step of: with 3,5-diio-2-hydroxybenzoic acid and di(trichloromethyl) carbonic ester as raw materials, reacting for 1-10 hours at the temperature of 40-150 DEG C in an organic solvent under the action of an organic amine catalyst, and processing reaction liquid to obtain 3,5-diio-2-hydroxybenzene formyl chloride, wherein the charging mol ratio of the 3,5-diio-2-hydroxybenzoic acid to the di(trichloromethyl) carbonic ester is 1: (0.34-2.0), the charging mol ratio of the 3,5-diio-2-hydroxybenzoic acid to the organic amine is 1: (0.01-1.0), and the mass ratio of the organic solvent to the 3,5-diio-2-hydroxybenzene formyl chloride is (5-20): 1. The method disclosed by the invention has the advantages of available raw materials, low cost, simplicity and safety in operation, environmental friendliness and higher product yield and purity and has greater application value and good social and economical benefits.

Owner:ZHEJIANG RONGYAO CHEM +2

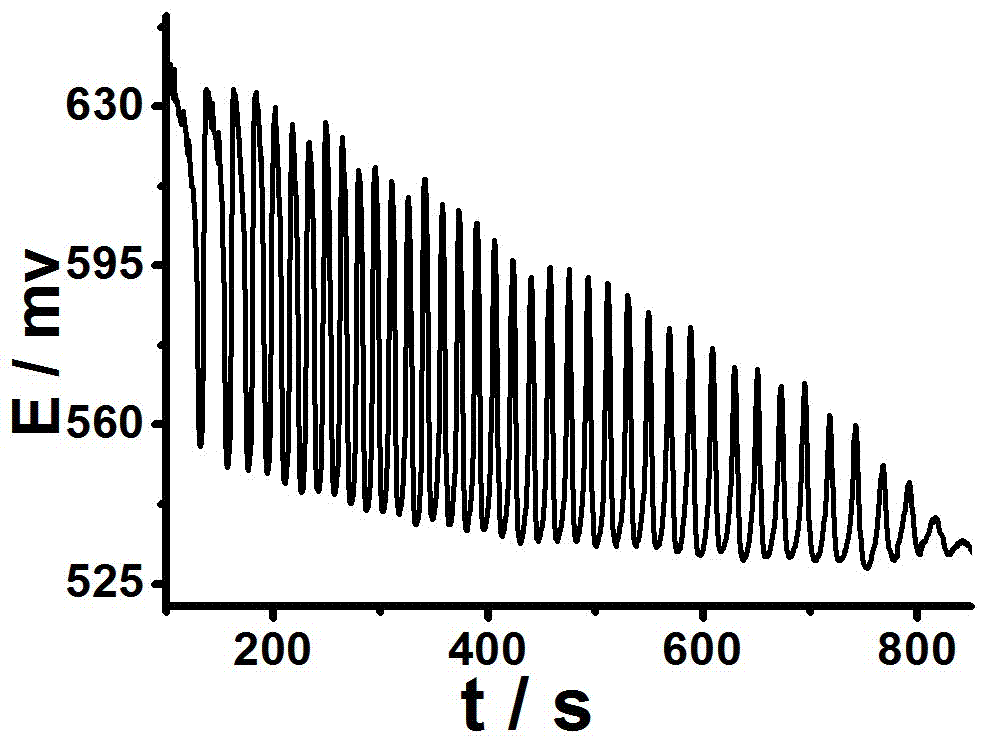

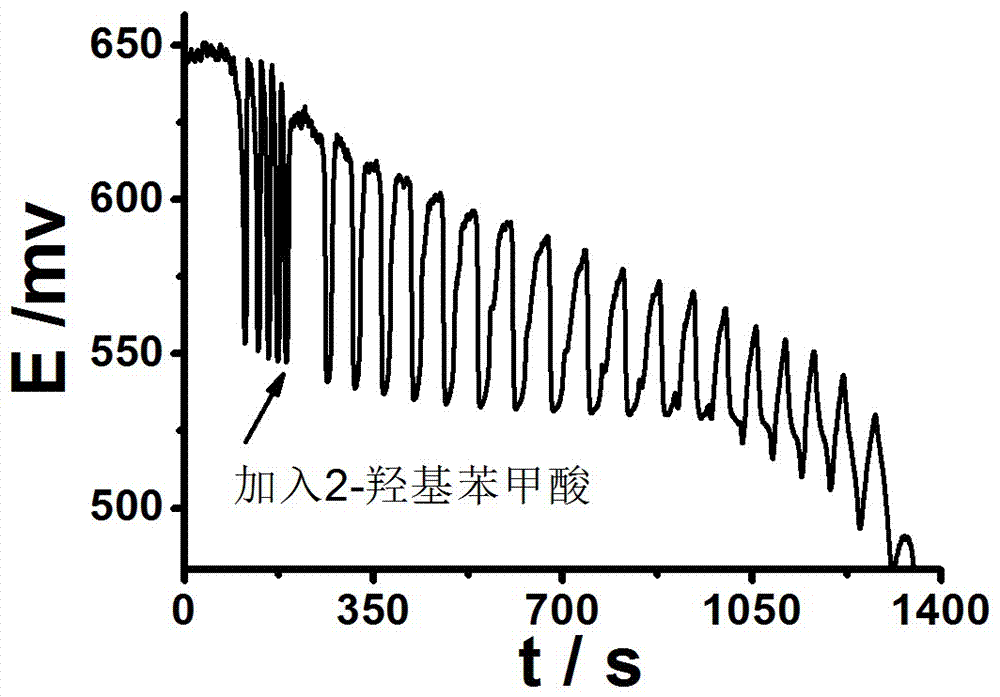

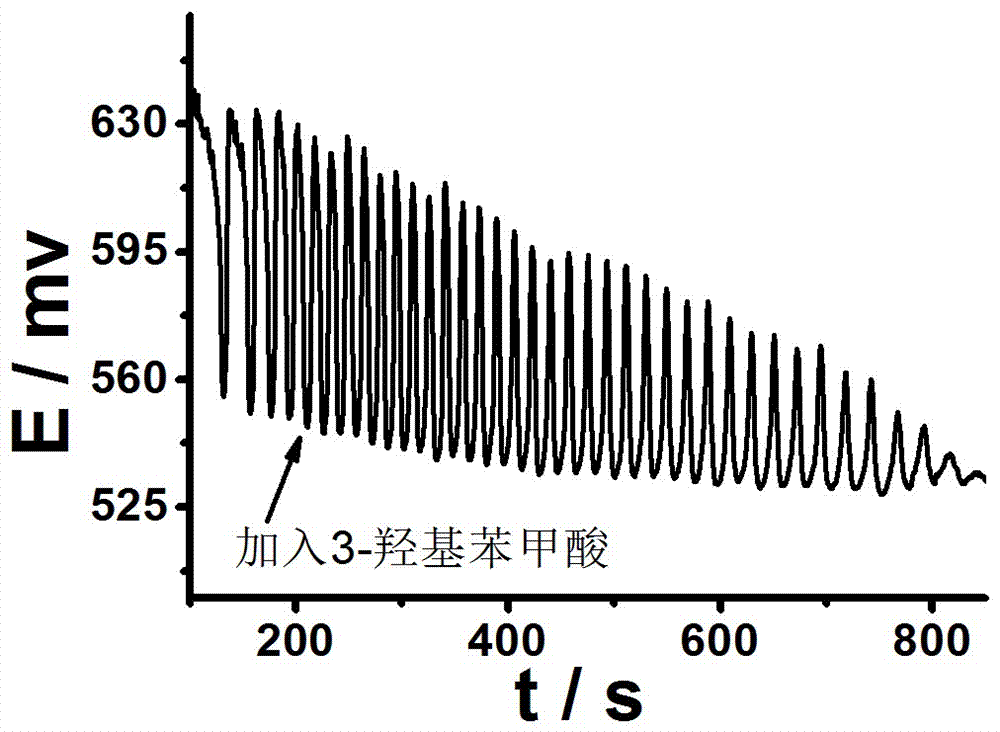

Method for identifying aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid

ActiveCN107045008ATime suppressionPreparing sample for investigationMaterial electrochemical variablesHydroxybenzoic acid2-Hydroxybenzoic acid

The invention discloses a method for identifying aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid. The method is characterized by comprising the following steps: taking a 'H2SO4-KIO3-[NiL](ClO4)2-propanedioic acid-H2O2' nonlinear oscillating chemical system as an identification solution, and further distinguishing and identifying the aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid according to oscillation response of the aromatic isomers on the system, wherein L in [NiL](ClO4)2 refers to 5,7,7,12,14,14-hexamethyl-1,4,8,11-tetraazamacrocyclo-4,11-diene. An oscillation spectrum provided by the identification method is intuitive, and the method is capable of conveniently and rapidly identifying the aromatic isomers 2-hydroxybenzoic acid and 3-hydroxybenzoic acid, can be widely applied to other isomers and is simple in equipment, high in accuracy and easy in operation and observation.

Owner:ANHUI UNIVERSITY

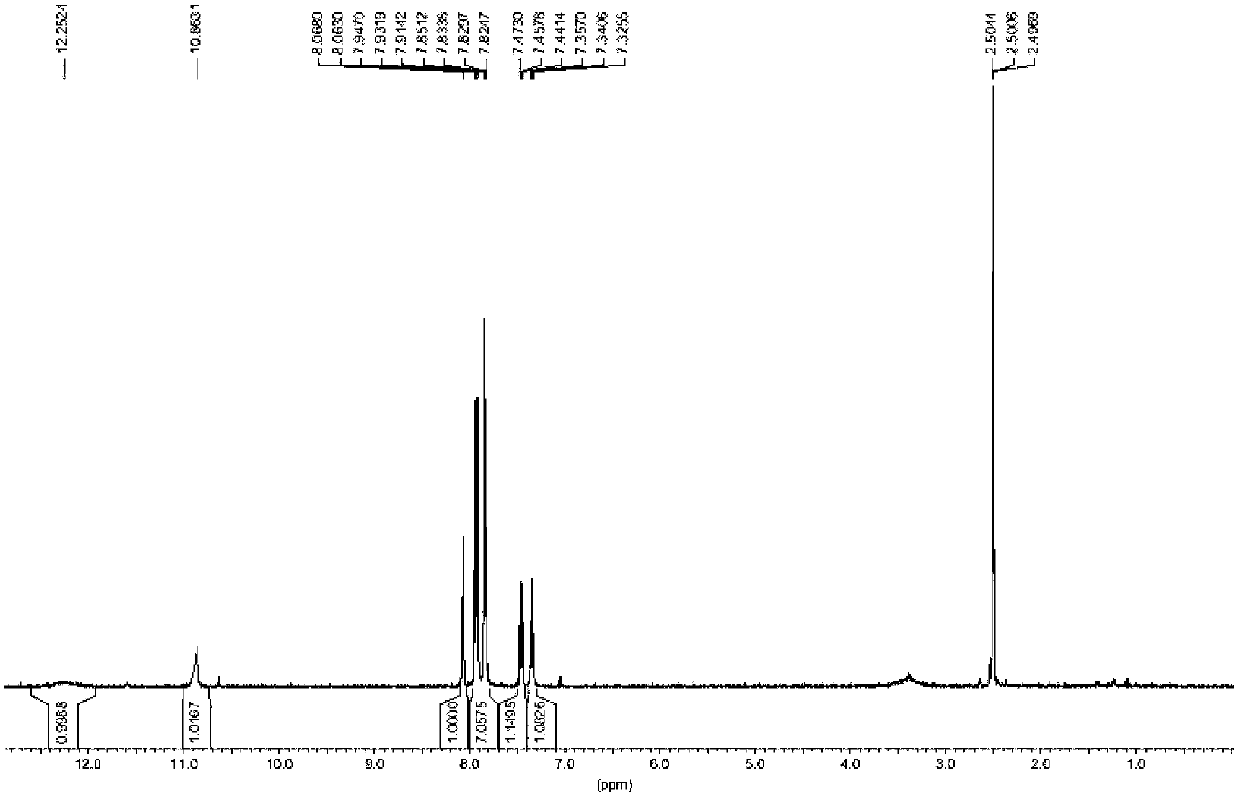

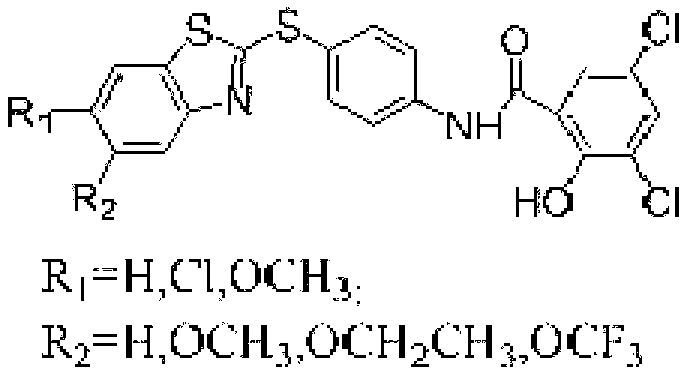

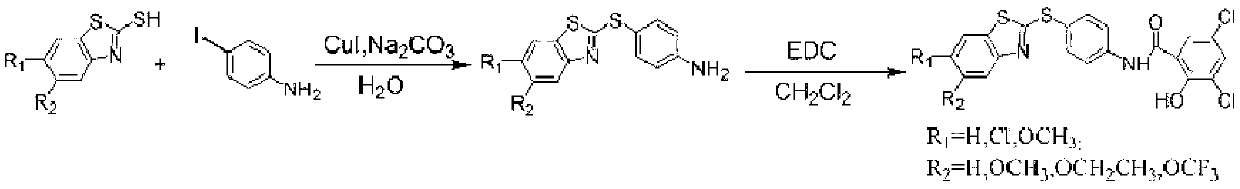

Preparation method of micromolecule cathepsin D inhibitor

ActiveCN103275034ARaw materials are cheap and easy to getSimple reaction conditionsOrganic chemistryAnilinePollution

The invention discloses a preparation method of a micromolecule cathepsin D inhibitor. The preparation method comprises the following steps that 2-mercaptobenzothiazole or its derivatives and 4-iodoaniline as starting materials undergo a reaction in a water phase by catalytic C-S coupling to produce 4-(2-benzothiazolylthio)aniline or its corresponding derivatives (A); and the 4-(2-benzothiazolylthio)aniline or its corresponding derivatives (A), and 3,5-dichloro-2-hydroxybenzoic acid undergo an amidation reaction to produce the micromolecule cathepsin D inhibitor (B). The preparation method has the advantages of easily available raw materials, simple reaction conditions, simple and convenient operation, low toxicity and pollution, simple post-treatment processes, high yield and high purity.

Owner:NANJING UNIV OF TECH

Ointment for treating psora

InactiveCN1927218AGood treatment effectNo side effectsSalicyclic acid active ingredientsAerosol deliveryMedicineSulfur

The invention provides an ointment for treating sabies, wherein the main constituents include sublimed sulfur, 2-hydroxybenzoic acid, cetyl alcohol, propylene glycol, methyl hydroxybenzoate, sodium dodecylsulfate, white Vaseline, white oil and distilled water.

Owner:TIANJIN WEALTH BIOENGINEERING SCI & TECH CO LTD

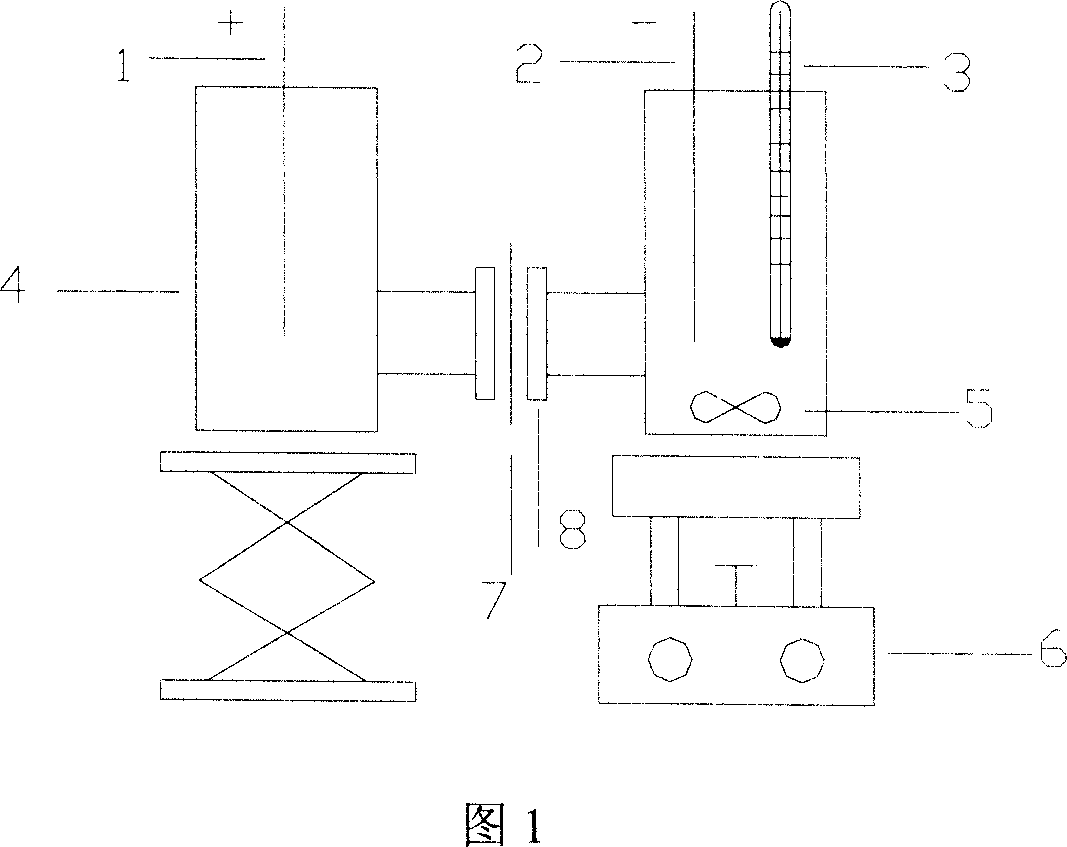

Method for salicylic acid electrolysis for preparing salicyic aldehyde

InactiveCN101008086AImprove current efficiencyOrganic chemistryElectrolysis componentsElectrolysisSalicylaldehyde

The invention relates to a direct electro-reduction method for preparing ortho-hydroxybenzaldehyde with 2-hydroxybenzoic acid in H type electrolyser, which is characterized in that quaternary ammonium salt addictive is added in cat electrode room. It takes lead plate as cathode and anode, takes ortho-hydroxybenzaldehyde and hydric sulphate as electrolytic solution for cathode and anode, the current efficiency reach over 35% at 10- 40 Deg. C and current density of 500- 2000 A / m2, which is 10% more than that without addictive.

Owner:EAST CHINA UNIV OF SCI & TECH

Compound medicinal tincture for treating tinea on manus and pedes

InactiveCN1546045ASignificant effectNo adverse reactionSalicyclic acid active ingredientsAntimycoticsMedicineCurative effect

A compound medicinal tinctura for treating extremity tinea prepared by charging 2-hydroxybenzoic acid, benzene carboxylic acid, boneol, wormseed tincture into the alcoholic solution proportionally and mixing. The preparation is a fusco-rufous liquid that can be directly daubed onto the affected parts.

Owner:刘辉

Medicine for treating ringworm of the nails and preparation method thereof

InactiveCN101011548AStrong antifungal powerNo side effectsHeavy metal active ingredientsAntimycoticsMomordicaPinellia

The invention relates to a pharmaceutical composition for treating ringworm of the nails and process for preparation, wherein the composition is prepared from pangolin scales, musk, clove, banksia rose, Cinnamomum cassia, cortex pseudolaricis, flavescent sophora root, roor of sessile stemona, Chinese dittany bark, hydnocarpus seed, pricklyash peel, Chinese honey locust, cicada shell, dragon's bone, jack-in-the-pulpit tuber, pinellia tuber, Sichuan aconite root, Kusnezoff monkshood root, camphor, lead monoxide, Halitum Violaceoum, red lead, momordica seed, 2-hydroxybenzoic acid and benzene carboxylic acid through steps of powdering, heating, fermenting and mixing the powders with 2-hydroxybenzoic acid and benzene carbonic acid.

Owner:张汉

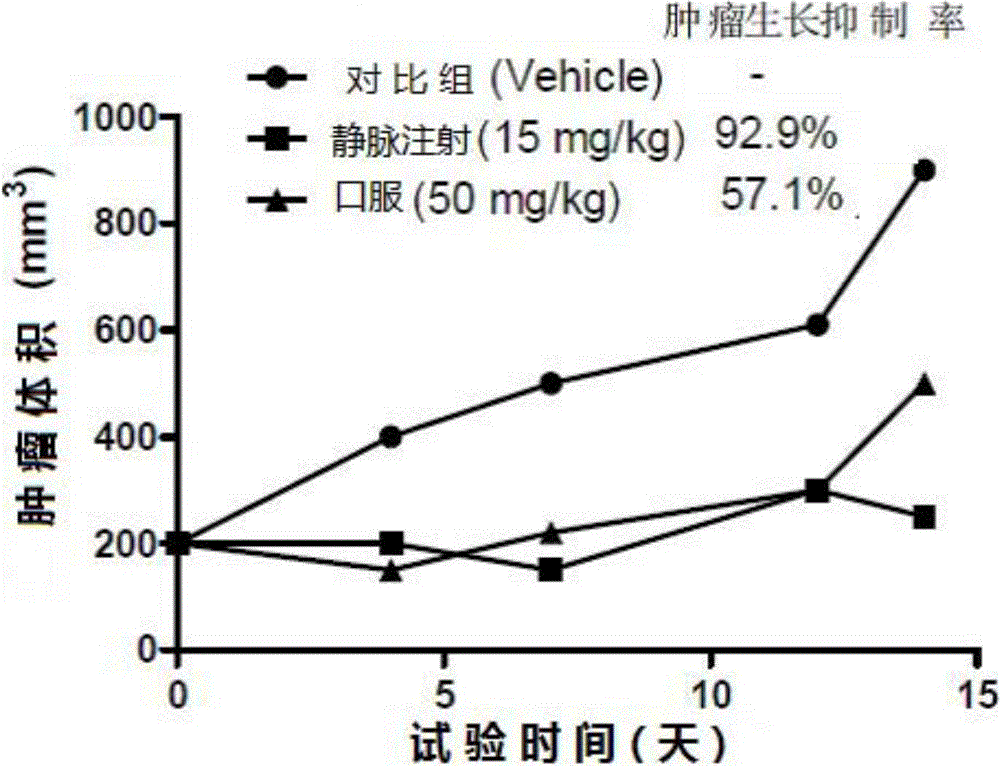

Imidazopyridine compound and preparation method and application thereof

ActiveCN105017245AGrowth inhibitionHigh activityOrganic active ingredientsOrganic chemistrySolventPhenyl group

The invention provides an imidazopyridine compound shown in the formula (1) and a preparation method and application thereof. The imidazopyridine compound shown in the formula (1) is obtained by taking 2-amidogen-4-hydroxypyridine, 4-bromine-2-methyl glyoxalidine hydroxybenzoate, dimethylethanolamine and 2-(trifluoromethyl)phenylethanol as the raw materials, taking alkali and metal catalysts as the catalysts and taking organic solvents as the solvents through multi-step reactions. The invention further provides the application of the imidazopyridine compound shown in the formula (1) which serves as an NEK2 inhibitor in regulating tumor cell growth.

Owner:EAST CHINA NORMAL UNIV

Light-resistant water-based environment-friendly stone-like paint and preparation method thereof

ActiveCN109868013AImprove light resistanceHigh strengthAnti-corrosive paintsWater basedAcrylic resin

The invention relates to light-resistant water-based environment-friendly stone-like paint and a preparation method thereof. A prepared modification filling material is added, and in the modificationfilling material, 2-hydroxybenzoic acid octyl ester can improve light resistance, and carboxymethyl cellulose can improve adhesion strength and stability of the internal structure; a water-based cosolvent and deionized water are added for dissolution and dispersion; a glacial acetic acid water solution can remove impurities in quartz sand, and fine holes formed by impurity removal impurities are to be filled, wherein the effect of the 2-hydroxybenzoic acid octyl ester and the carboxymethyl cellulose can be fully exerted by the fine pore structure, and the internal adhesion strength and stability can be improved. According to the technical scheme, a water-based acrylic resin emulsion is used, and the characteristics of weather resistance, light resistance, heat resistance, corrosion resistance, film coating fullness and the like of the water-based acrylic resin emulsion are fully exerted; and then a coalescing agent and a defoaming agent with a certain ratio are added to obtain the light-resistant water-based environment-friendly real stone-like paint which has the characteristics of good light resistance, strong adhesion, stable structure, no powder falling and the like.

Owner:哈尔滨绿科科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com