Method for salicylic acid electrolysis for preparing salicyic aldehyde

A technology of salicylic acid and salicylaldehyde, applied in the electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of low product purity, complex catholyte composition, low current efficiency and conversion rate of electrolytic reduction method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] All percentages in the examples are percentages by mass.

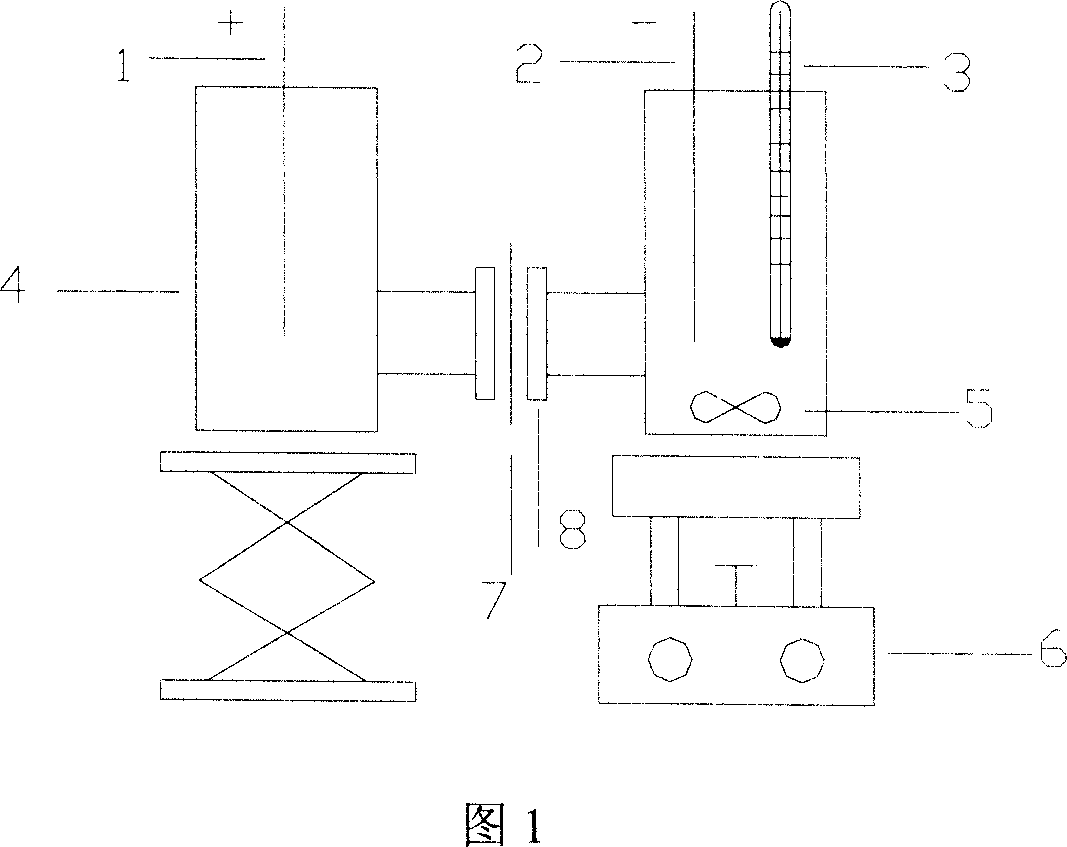

[0039] Use flat lead as the cathode and anode, and the area of the lead cathode is 15cm 2 (2.5×6cm). An ion exchange membrane is used as the diaphragm. When the electrolysis started, the anolyte was 250ml concentration of 15% sulfuric acid solution, and the catholyte was 220ml concentration of 20% sodium bisulfite solution and 5.0 grams of salicylic acid. Stir the catholyte with a magnetic stirrer. The applied current is 1.5A, and the current density is 1000A / m 2 . The catholyte temperature was 20±2°C. The actual power-on time is 1 hour and 30 minutes. The results of electrolysis are as follows:

Embodiment 2

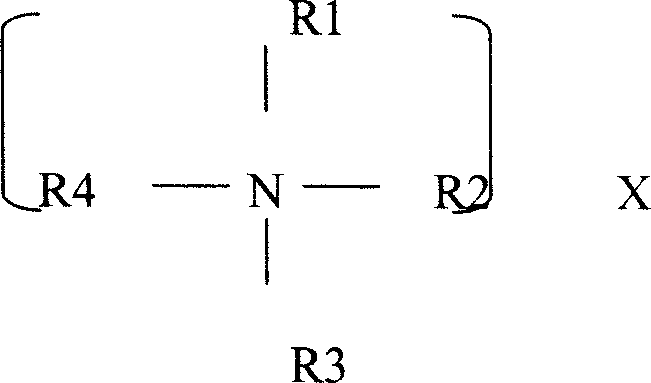

[0042] Electrode, anolyte, current density, electrolysis temperature, electrolysis time and diaphragm are the same as Comparative Example 3. Catholyte is 220ml concentration and is the tetrapentylammonium bromide solution of 20% sodium bisulfite solution and 5.0 grams of salicylic acid and 10ml0.5g / L. The results of electrolysis are as follows:

Embodiment 3

[0045] Electrode, anolyte, current density, electrolysis temperature, electrolysis time and diaphragm are the same as Comparative Example 3. Catholyte was 20% sodium bisulfite solution and 5.0 gram salicylic acid and 5ml concentration was the tetramethylammonium hydroxide solution of 0.5g / L when electrolysis started. The results of electrolysis are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com