Outer plugging resin and preparation method thereof

A technology of plug hole and resin, which is applied in the field of resin, can solve the problems of affecting the production capacity of the grinding plate, the grinding is not clean, the copper thickness of the plate is deformed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation steps of described modified epoxy resin are as follows:

[0032] (1) preparation of tetrabromobisphenol A type epoxy resin:

[0033] Add tetrabromobisphenol A, epichlorohydrin, and 80% isopropanol aqueous solution into the reactor, under nitrogen protection, stir until completely dissolved, then add dropwise 50% sodium hydroxide aqueous solution, The temperature is raised to 55°C, and the heat preservation reaction is carried out for 1 hour. The weight ratio is 1: 1.3: 3: 0.002; the temperature is raised to 65°C, and an aqueous sodium hydroxide solution with a mass fraction of 50% is added dropwise, and the heat preservation reaction is carried out for 1 hour. The tetrabromobisphenol A and the hydrogen with a mass fraction of 50% are The weight ratio of the sodium oxide aqueous solution is 1:0.002; the temperature is raised to 75° C., and the sodium hydroxide aqueous solution with a mass fraction of 50% is added dropwise, and the heat preservation react...

Embodiment 1

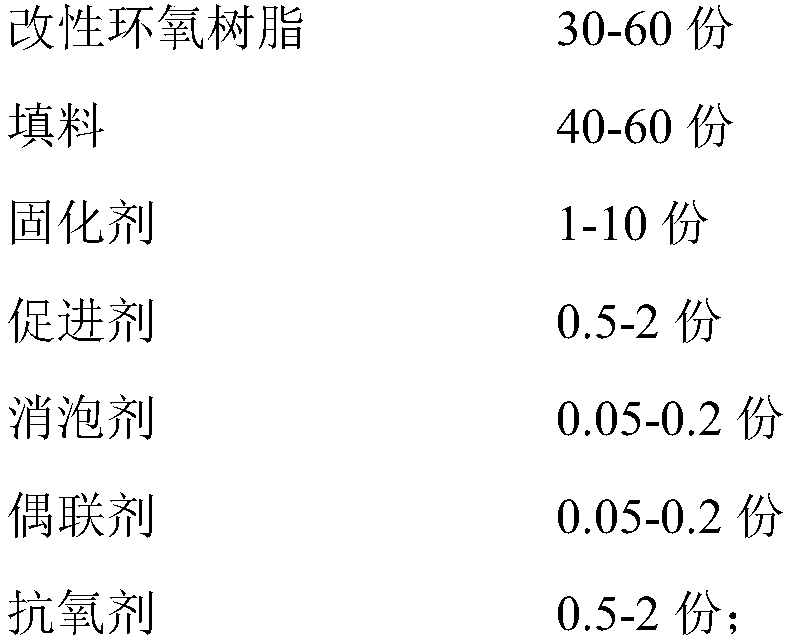

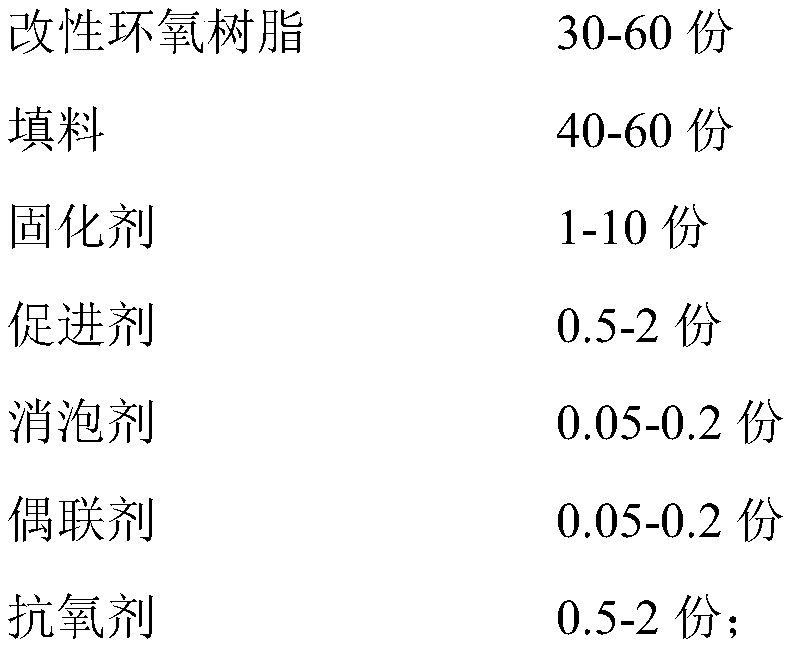

[0067] Calculated in parts by weight, the outer layer plugging resin includes:

[0068]

[0069] Wherein, the modified epoxy resin is 4-benzamide-2-hydroxybenzoic acid modified tetrabromobisphenol A type epoxy resin; the filler is modified talcum powder, modified carbon nanotube, modified nano Calcium carbonate, the weight ratio of the modified talcum powder to the modified carbon nanotubes and the modified nano-calcium carbonate is 1:2.4:0.8; the curing agent is a latent curing agent, and the latent curing The agent is diaminodiphenylmethane; the accelerator is 2-ethylimidazole; the defoamer is polydimethylsiloxane; the coupling agent is KH560; the antioxidant is 3- Hydroxy-3-methyl-2-butanone oxime;

[0070] The preparation method of the outer layer plugging resin comprises the following steps:

[0071] Put the modified epoxy resin, filler, curing agent, accelerator, defoamer, coupling agent, and antioxidant in a disperser and stir for 1 hour in parts by weight, mix eve...

Embodiment 2

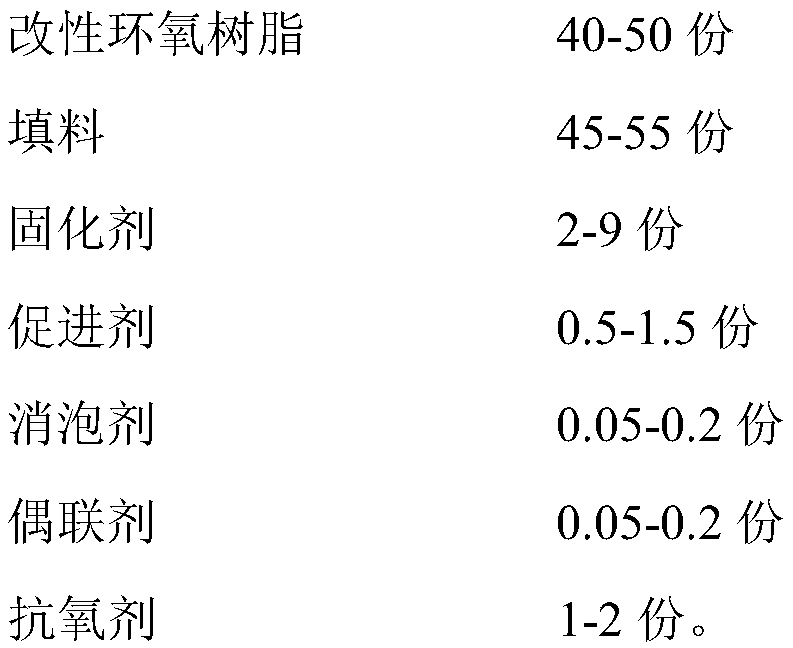

[0077] Calculated in parts by weight, the outer layer plugging resin includes:

[0078]

[0079]Wherein, the modified epoxy resin is 4-benzamide-2-hydroxybenzoic acid modified tetrabromobisphenol A type epoxy resin; the filler is modified talcum powder, modified carbon nanotube, modified nano Calcium carbonate, the weight ratio of the modified talcum powder to the modified carbon nanotubes and the modified nano-calcium carbonate is 1:2.4:0.8; the curing agent is a latent curing agent, and the latent curing The agent is diaminodiphenylmethane; the accelerator is 2-ethylimidazole; the defoamer is polydimethylsiloxane; the coupling agent is KH560; the antioxidant is 3- Hydroxy-3-methyl-2-butanone oxime;

[0080] The preparation method of the outer layer plugging resin and the preparation steps of the modified epoxy resin are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com