Light-resistant water-based environment-friendly stone-like paint and preparation method thereof

A real stone paint, water-based technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of poor light resistance of real stone paint, and achieve the goal of improving internal adhesion strength and stability, improving light resistance, and improving adhesion strength and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

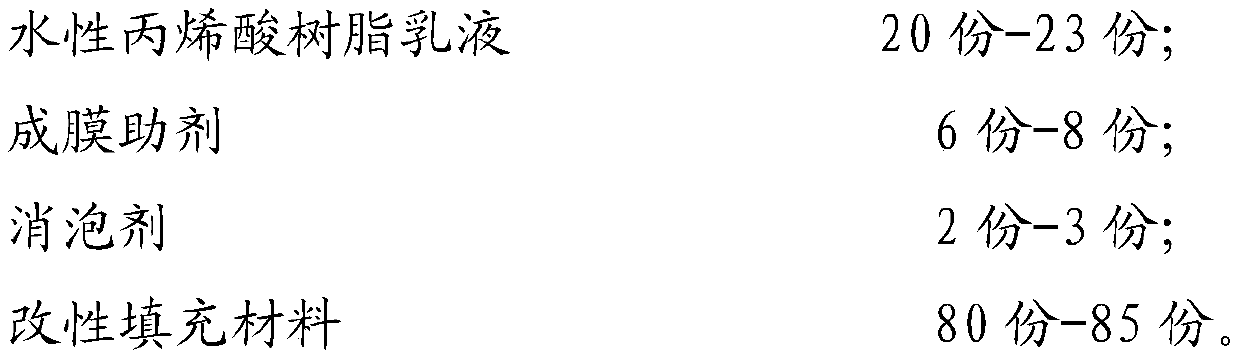

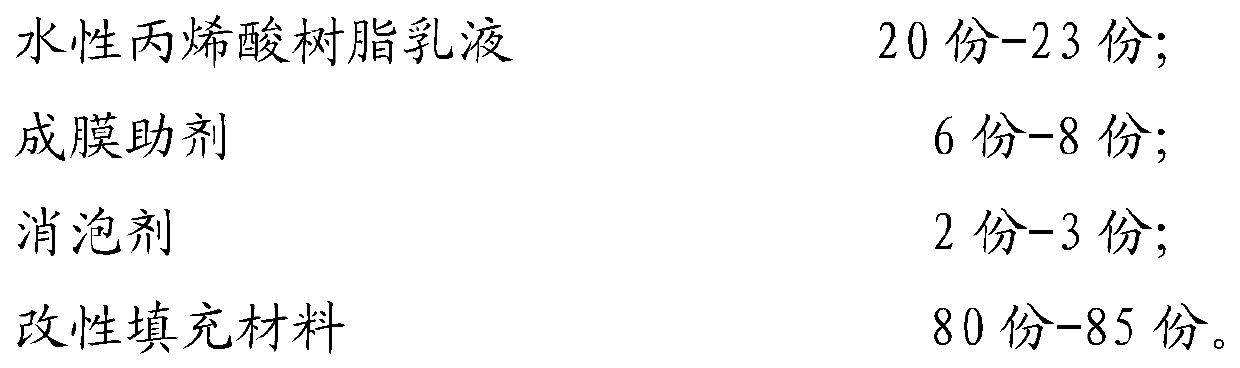

[0033] The application also provides a preparation method for preparing any one of the above-mentioned light-resistant water-based environmental protection real stone paints, comprising the following steps:

[0034] 1) First add 20-23 parts of water-based acrylic resin emulsion to 80-85 parts of modified filling material, keep the constant temperature at 50°C, and fully stir for 8-10 minutes;

[0035] 2) Add 6-8 parts of film-forming aid and 2-3 parts of defoamer, stir for 8-15 minutes, cool down to room temperature naturally, and pack to obtain the finished product.

preparation example 1

[0038] The preparation method of modified filling material comprises the following steps:

[0039] 1) Soak 50 parts of quartz sand in 25 parts by weight of 15% glacial acetic acid aqueous solution and stir for 5 minutes, filter and dry;

[0040] 2) Add 5 parts of octyl 2-hydroxybenzoate to the dried quartz sand and mix and stir for 2 minutes;

[0041] 3) Add 5 parts of carboxymethyl cellulose, 4 parts of alcohol ether water-based co-solvent and 76 parts of deionized water and mix and stir for 5 minutes;

[0042] 4) Stop stirring, and filter out part of the liquid so that the solid content accounts for 50% of the total weight, that is, the modified filling material is obtained.

preparation example 2

[0044] The preparation method of modified filling material comprises the following steps:

[0045] 1) Soak 55 parts of quartz sand in 27 parts by weight of 20% glacial acetic acid aqueous solution and stir for 10 minutes, filter and dry;

[0046] 2) Add 8 parts of octyl 2-hydroxybenzoate to the dried quartz sand and mix and stir for 5 minutes;

[0047] 3) Add 8 parts of carboxymethyl cellulose, 5 parts of alcohol ether water-based co-solvent and 80 parts of deionized water and mix and stir for 10 minutes;

[0048] 4) Stop stirring, and filter out part of the liquid so that the solid content accounts for 50% of the total weight, that is, the modified filling material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com