Light-emitting diode (LED) fluorescent glue

A technology of fluorescent glue and silica gel, which is applied in the field of LED fluorescent glue and phosphor powder preparation, which can solve the problems of low effective conversion efficiency of phosphor powder, large light decay, and poor luminous stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further describe the present invention, the LED fluorescent glue of the present invention will be further described below in conjunction with examples.

[0038] According to the components and contents (% by weight) listed in Table 1, the LED fluorescent glue was prepared. All components are commercially available.

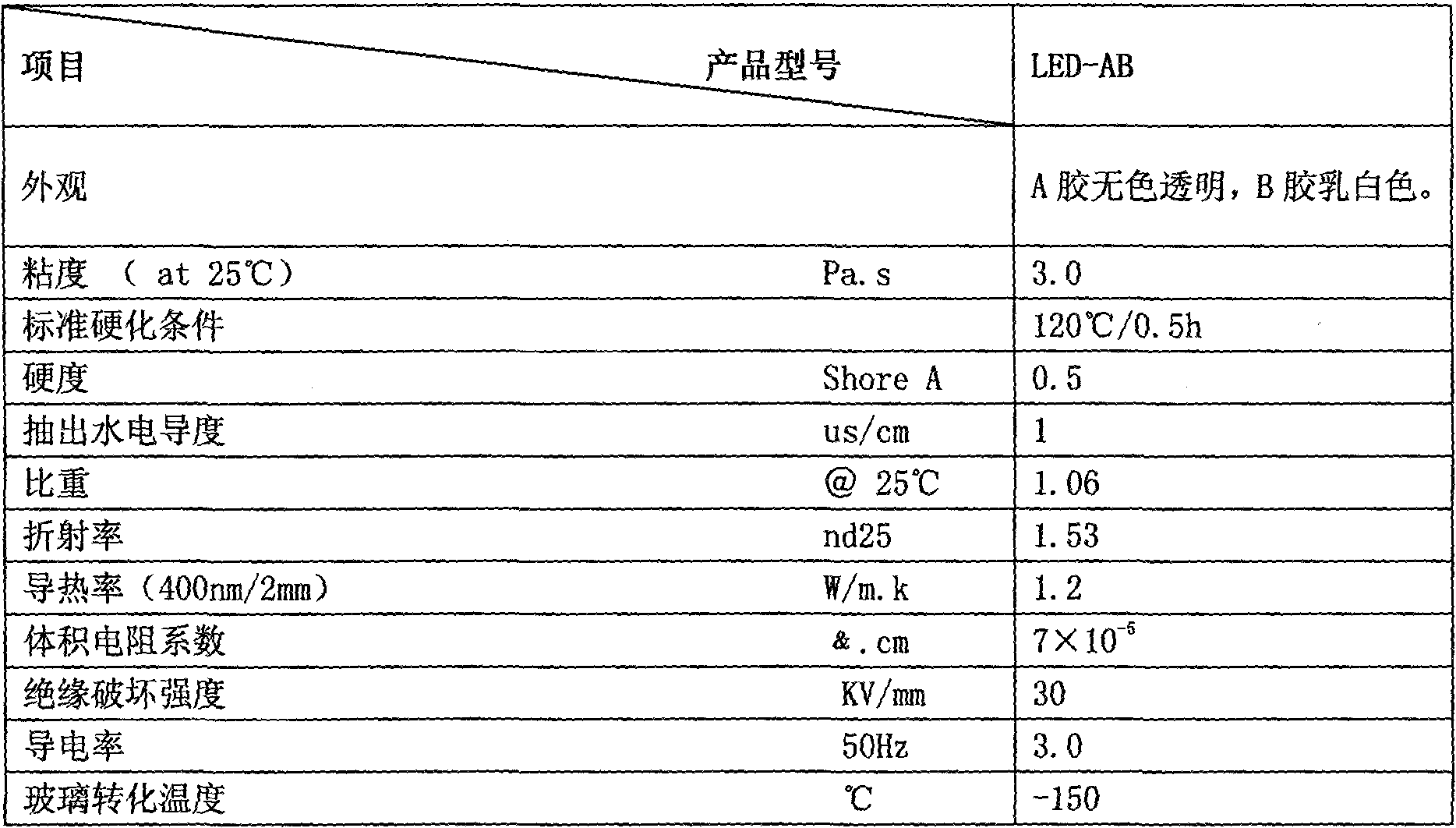

[0039] Table 1 LED fluorescent glue components and content (100% by weight)

[0040]

Example

1

Example

2

Example

3

Example

4

Example

5

OE-6450A (silicone main agent)

3.10

3.40

3.24

3.1

3.20

OE-6450B (silicone curing agent)

2.90

2.80

2.76

2.6

2.75

TO powder (diffusion agent)

73.81

72.8

74.1

75.54

74.2

Silica powder (SiO 2 )

6.4

7.0

6.7

6.3

6.75

Aluminum oxide powder (Al 2 o 3 )

11.8

11.76

11.2

10.6

11.0

ST-11001 (Silicone) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com