Method for preparing porous ceramic material

A technology of porous ceramics and composite materials, applied in ceramic products, applications, household appliances, etc., can solve the problems of long preparation cycle and complicated porous ceramic process, and achieve the effect of short cycle, low cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

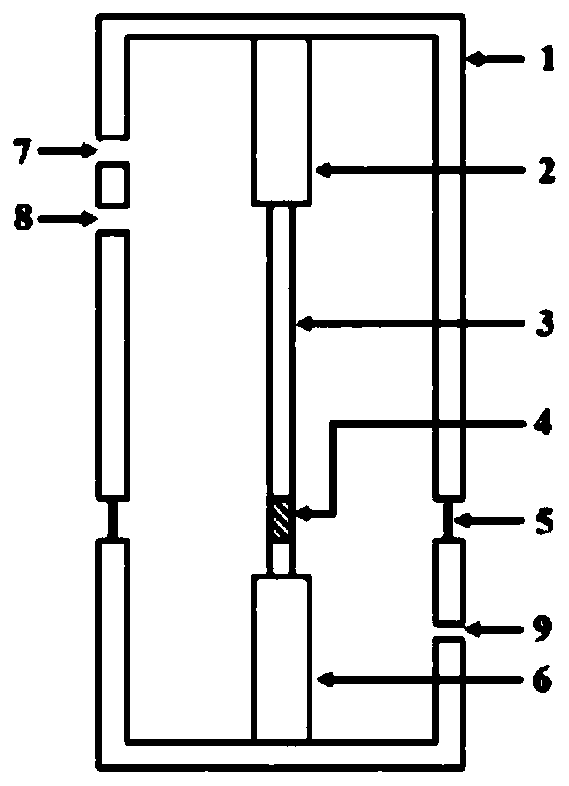

Method used

Image

Examples

Embodiment 1

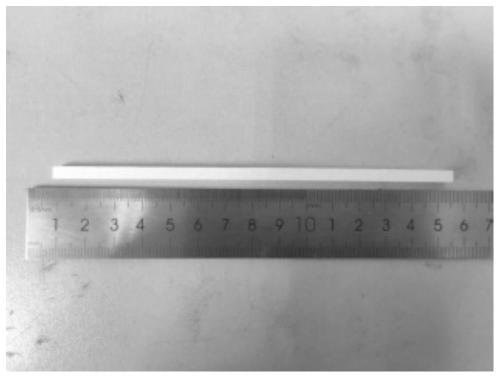

[0027] This embodiment is a method for preparing porous oxide eutectic ceramics by using laser suspension zone melting high-gradient directional solidification technology. The specific process is:

[0028] Step one, prepare Al 2 O 3 -YAG-ZrO 2 Eutectic component oxide composite material preform: Al with a purity of 99.99% 2 O 3 , Y 2 O 3 And ZrO 2 Oxide powder as raw material, press Al 2 O 3 / Y 2 O 3 / ZrO 2 The eutectic point ratio of the phase diagram. The raw material is mixed with deionized water and polyvinyl chloride, the raw material: deionized water: polyvinyl chloride=20:20:1, and the ratio is a mass ratio to obtain a mixture. The mixture was placed in a zirconia ball milling tank, and then ball milled with a planetary mill at a speed of 550r / min for 5 hours, and then placed in a drying oven with a temperature of 80°C for 2 hours. Pass the dried powder through a 40-mesh sieve to obtain a uniform raw material powder.

[0029] The obtained uniform raw material powder is comp...

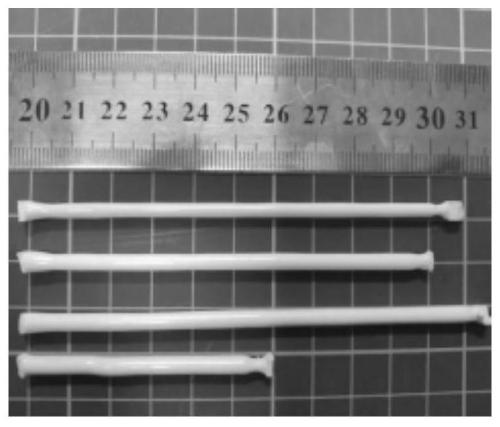

Embodiment 2

[0034] This embodiment is a method for preparing porous oxide eutectic ceramics by using laser suspension zone melting high-gradient directional solidification technology. The specific process is:

[0035] Step one, prepare Al 2 O 3 -YAG-ZrO 2 Eutectic component oxide composite material preform: Al with a purity of 99.99% 2 O 3 , Y 2 O 3 And ZrO 2 Oxide powder as raw material, press Al 2 O 3 / Y 2 O 3 / ZrO 2 The eutectic point ratio of the phase diagram. The raw material is mixed with deionized water and polyvinyl chloride, the raw material: deionized water: polyvinyl chloride=20:20:1, and the ratio is a mass ratio to obtain a mixture. The mixture was placed in a zirconia ball milling tank, and then ball milled with a planetary mill at a speed of 550r / min for 5 hours, and then placed in a drying oven with a temperature of 80°C for 2 hours. Pass the dried powder through a 40-mesh sieve to obtain a uniform raw material powder.

[0036] The obtained uniform raw material powder is comp...

Embodiment 3

[0040] This embodiment is a method for preparing porous oxide eutectic ceramics by using laser suspension zone melting high-gradient directional solidification technology. The specific process is:

[0041] Step one, prepare Al 2 O 3 -YAG eutectic composition oxide composite material preform: Al with a purity of 99.99% 2 O 3 , Y 2 O 3 Oxide powder as raw material, press Al 2 O 3 / Y 2 O 3 The eutectic point ratio of the phase diagram. The raw material is mixed with deionized water and polyvinyl chloride, the raw material: deionized water: polyvinyl chloride=20:20:1, and the ratio is a mass ratio to obtain a mixture. The mixture was placed in a zirconia ball mill tank, and then ball milled by a planetary ball mill at a speed of 550 r / min for 5 hours, and then placed in a drying oven with a temperature of 80°C for 2 hours. Pass the dried powder through a 40-mesh sieve to obtain a uniform raw material powder.

[0042] The obtained uniform raw material powder is compression molded. Dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com