Ultrathin nanosheet array electro-catalytic material with nano-porous structure and oxygen vacancies

A nanosheet array and electrocatalytic material technology, applied in the field of ultra-thin nanosheet array electrocatalytic materials, can solve the problems of poor stability and low catalyst activity, achieve good stability, increase specific surface area, and improve adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

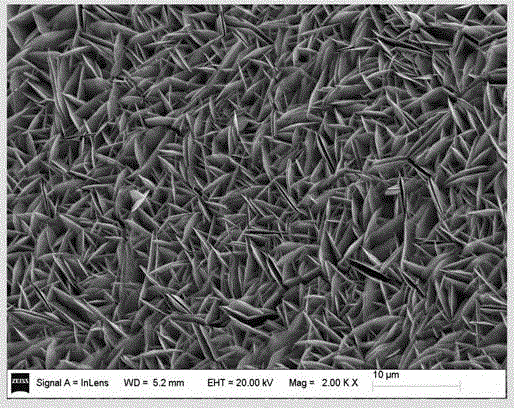

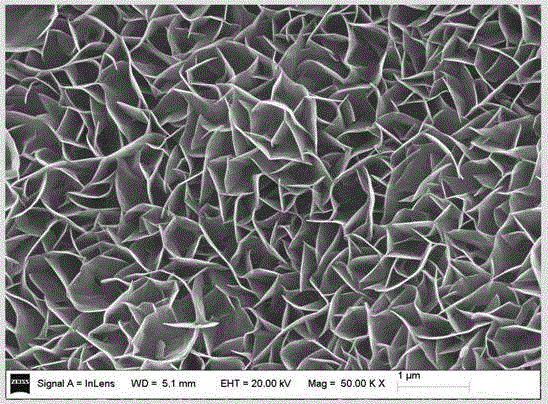

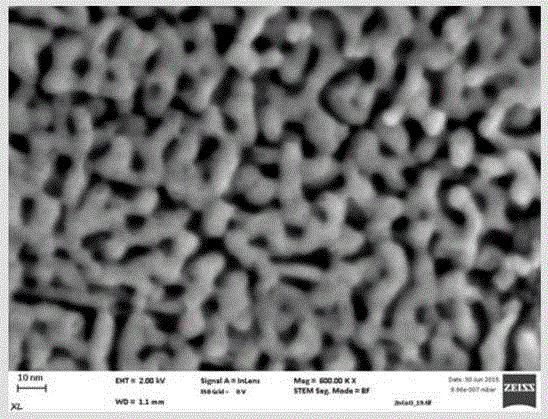

[0034]An electrocatalytic material with a nanoporous structure and an oxygen vacancy ultra-thin nanosheet array, which is a metal-doped tricobalt tetroxide primary nanosheet array grown perpendicular to the substrate on a conductive substrate, and each of the primary nanosheets is obtained with Oxygen vacancies and nanoporous ultrathin nanosheets, the conductive substrate is a titanium sheet, the doped metal is zinc, and the molar ratio of the doped metal to cobalt is 0.5:1; the thickness of the metal-doped cobalt tetraoxide ultrathin nanosheet is 1.22nm, the nanosheet has a three-dimensional porous structure, and the nanopore diameter is 3.6nm

[0035] The preparation method of the ultrathin nanosheet array electrocatalytic material having a nanoporous structure and oxygen vacancies comprises the following steps:

[0036] 1) Prepare the first aqueous solution of hydrochloric acid with a concentration of 1 mol / liter, put the conductive substrate into the hydrochloric acid solu...

Embodiment 2

[0058] An electrocatalytic material with a nanoporous structure and an oxygen vacancy ultra-thin nanosheet array, which is a metal-doped tricobalt tetroxide primary nanosheet array grown perpendicular to the substrate on a conductive substrate, and each of the primary nanosheets is obtained with Oxygen vacancies and nanoporous ultrathin nanosheets, the conductive substrate is a titanium sheet, the doped metal is nickel, and the molar ratio of the doped metal to cobalt is 1:1; the thickness of the metal-doped cobalt tetraoxide ultrathin nanosheet is The nanosheet has a three-dimensional porous structure with a nanopore diameter of 3.9nm.

[0059] The preparation method of the electrocatalytic material is basically the same as in Example 1, except that the zinc nitrate in steps 2 and 3 is replaced with nickel nitrate.

Embodiment 3

[0061] An electrocatalytic material with a nanoporous structure and an oxygen vacancy ultra-thin nanosheet array, which is a metal-doped tricobalt tetroxide primary nanosheet array grown perpendicular to the substrate on a conductive substrate, and each of the primary nanosheets is obtained with Oxygen vacancies and nanoporous ultrathin nanosheets, the conductive substrate is nickel foam, the doped metal is zinc, and the molar ratio of doped metal to cobalt is 0.5:1; metal-doped cobalt tetraoxide ultrathin nanosheets The thickness is 1.5nm, and the nanosheet has a three-dimensional porous structure with a nanopore diameter of 5nm.

[0062] The preparation method of the electrocatalytic material is the same as that of Example 1. The obtained material is similar to the material obtained in Example 1 in appearance and performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com