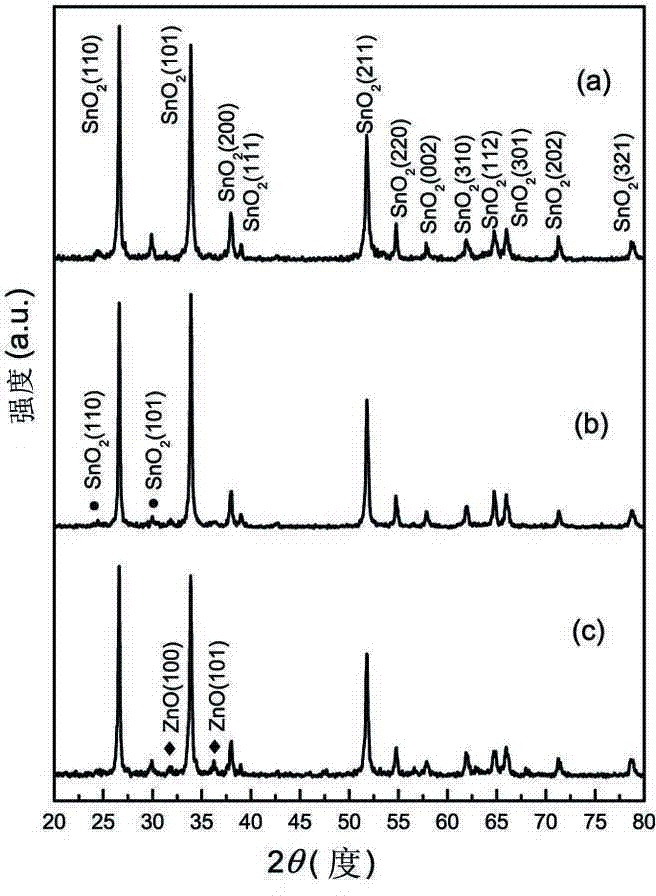

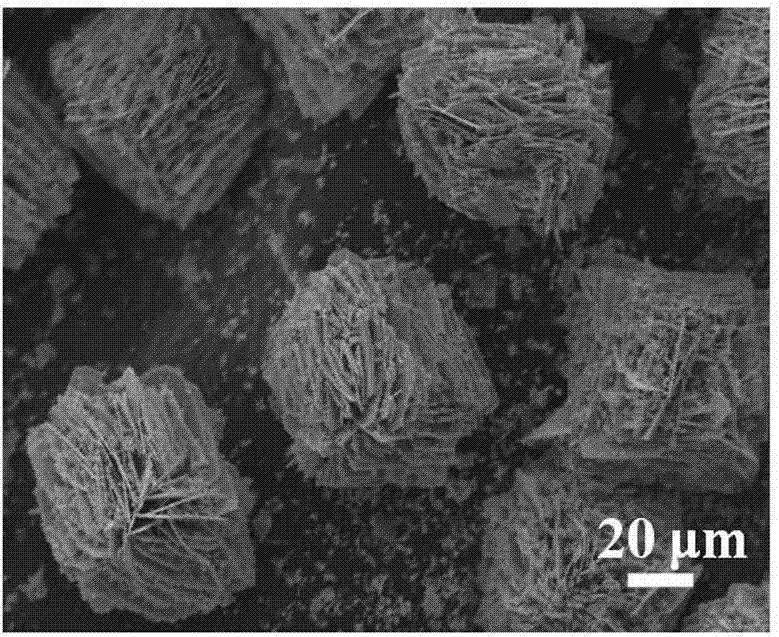

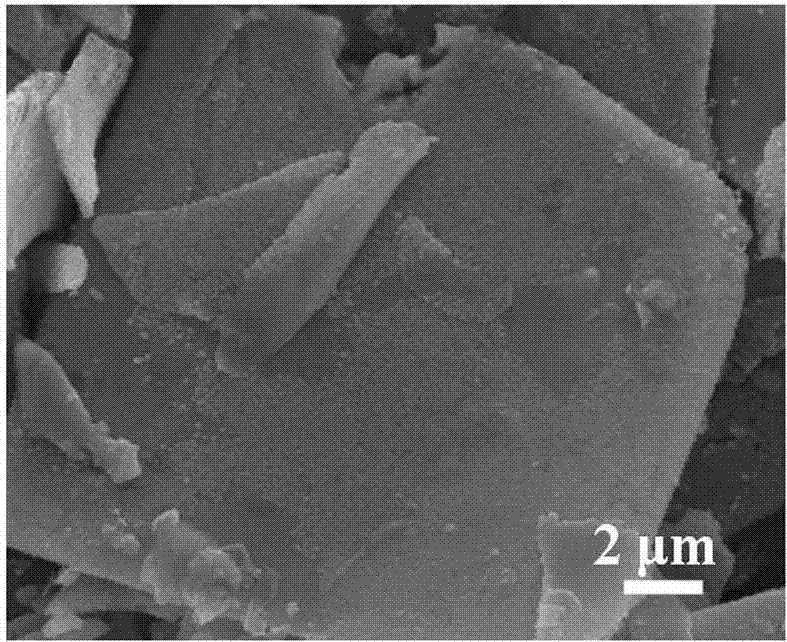

ZnO/SnO2 nano composite gas-sensitive material with flower-shaped grading structure and preparation method of material

A gas-sensitive material, flower-like classification technology, applied in analytical materials, nanotechnology, nanotechnology and other directions, to achieve the effects of good gas sensitivity, improved gas sensitivity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately weighed 1.822 g CTAB and 1.286 g SnCl 2 2H 2 O was added to 40 mL of absolute ethanol, and stirred until the solid was completely dissolved. 5 mL of 3 M NaOH aqueous solution was added dropwise to the above solution with stirring, and stirring was continued for 10 min after the dropwise addition was completed. The obtained solution was placed in a reaction kettle and reacted at 130°C for 15 h. After the reaction, the reaction kettle was naturally cooled to room temperature. The obtained precipitate was washed 4 times with deionized water and ethanol respectively. After centrifugation, it was dried at 60°C for 12 h. , to prepare SnO ???? Powder. Add 0.5 g of SnO powder prepared above to 20 ml containing 0.66 g Zn(CH 3 COO) 2 · 2H 2 O aqueous solution, after ultrasonic treatment for 10 min, the solvent was distilled off under reduced pressure to obtain ZnO / SnO 2 Precursors for nanocomposites. ZnO / SnO obtained in air atmosphere 2 The nanocomposite pre...

Embodiment 2

[0032] Accurately weighed 2.733 g CTAB and 1.929 g SnCl 2 2H 2 O was added to 60 mL of absolute ethanol, and stirred until the solid was completely dissolved. 7.5 mL of 3 M NaOH aqueous solution was added dropwise to the above solution with stirring, and stirring was continued for 10 min after the dropwise addition. The obtained solution was placed in a reaction kettle and reacted at 130°C for 12 h. After the reaction, the reaction kettle was naturally cooled to room temperature. The obtained precipitate was washed 4 times with deionized water and ethanol respectively. After centrifugation, it was dried at 60°C for 12 h. , to prepare SnO ???? Powder. Disperse 0.8 g of SnO powder prepared above in 20 ml containing 1.07 g Zn(CH 3 COO) 2 · 2H 2 O aqueous solution, after ultrasonic treatment for 10 min, the solvent was removed by low-temperature thermal evaporation, and ZnO / SnO 2 Precursors for nanocomposites. ZnO / SnO obtained in air atmosphere 2 The nanocomposite precu...

Embodiment 3

[0035] Accurately weighed 1.822 g CTAB and 1.286 g SnCl 2 2H 2 O was added to 40 mL of absolute ethanol, and stirred until the solid was completely dissolved. 5 mL of 3 M NaOH aqueous solution was added dropwise to the above solution with stirring, and stirring was continued for 10 min after the dropwise addition was completed. The obtained solution was placed in a reaction kettle and reacted at 130°C for 15 h. After the reaction, the reaction kettle was naturally cooled to room temperature. The obtained precipitate was washed 4 times with deionized water and ethanol respectively. After centrifugation, it was dried at 60°C for 12 h. , to prepare SnO ???? Powder. Disperse 0.5 g of SnO powder prepared above in 20 ml containing 0.32 g Zn(CH 3 COO) 2 · 2H 2 O aqueous solution, after ultrasonic treatment for 10 min, the solvent was distilled off under reduced pressure to obtain ZnO / SnO 2 Precursors for nanocomposites. ZnO / SnO obtained in air atmosphere 2 The nanocomposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com