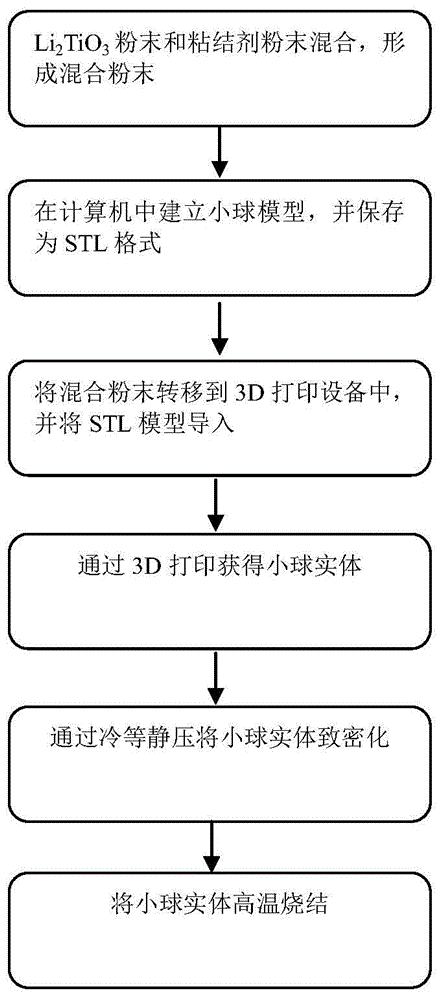

Method for quickly manufacturing Li2TiO3 tritium breeding small balls

A technology of tritium multiplication and small balls, which is applied in the field of 3D printing, can solve the problems of high requirements, poor experimental repeatability, and wide particle size distribution of small balls, and achieve the effect of uniform particle size distribution, high density, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

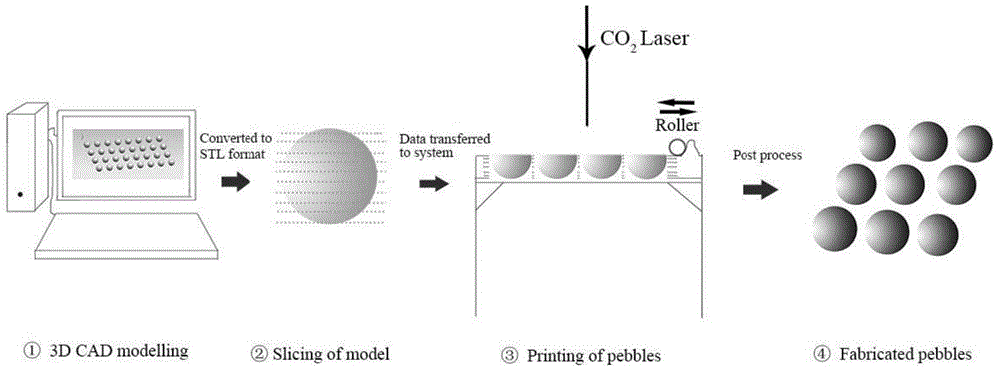

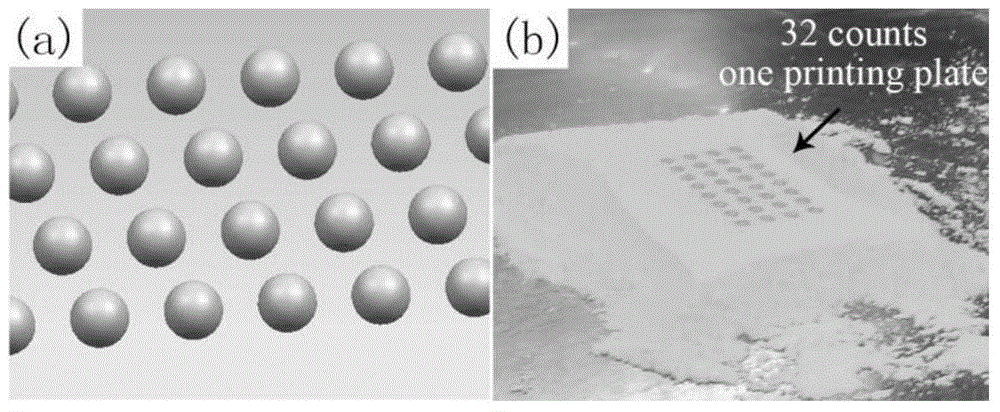

[0026] 25g of Li 2 TiO 3 The powder and 2.78g of binder powder are evenly mixed (the binder powder is made of epoxy resin, stearic acid or nylon), spread on the workbench of the 3D printing equipment, and then the three-dimensional model of the ball (diameter 4mm , STL format) into the system of the 3D printing equipment, set the working parameters of the equipment (laser power: 20W, laser beam diameter: 200μm, scanning distance: 200μm, scanning speed: 2000mm / s), and start scanning layer by layer. The obtained pellets were transferred to a cold isostatic press, and the applied pressure was 300 MPa, and the pressure was maintained for 30 minutes to obtain relatively dense pellets. Then the pellets are moved into a resistance furnace for debinding treatment. After cooling, they are sintered in a high-temperature furnace at a sintering temperature of 850°C and a holding time of 2 hours to obtain Li 2 TiO 3 Ball entity.

[0027] figure 2 It is a schematic diagram of the proc...

Embodiment 2

[0032] 25g of Li 2 TiO 3 Mix the powder and 6.25g of binder powder evenly (the material used for the binder powder is epoxy resin, stearic acid or nylon), spread it on the workbench of the 3D printing equipment, and then put the three-dimensional model of the ball (diameter 4mm , STL format) into the system, set the equipment working parameters (laser power: 20W, laser beam diameter: 200μm, scanning distance: 200μm, scanning rate: 2000mm / s), and start scanning layer by layer. The obtained pellets were transferred to a cold isostatic press, and the applied pressure was 300 MPa, and the pressure was maintained for 30 minutes to obtain relatively dense pellets. Then the pellets are moved into a resistance furnace for debinding treatment. After cooling, they are sintered in a high-temperature furnace at a sintering temperature of 650-950°C and a holding time of 2 hours to obtain Li 2 TiO 3 Ball entity.

[0033] In this embodiment measured by the Archimedes drainage method, whe...

Embodiment 3

[0037] 25g of Li 2TiO 3 Mix the powder and 10.7g of epoxy resin powder evenly, spread it on the workbench of the 3D printing equipment, then import the three-dimensional model of the ball (4mm in diameter, STL format) into the system, and set the working parameters of the equipment (laser power: 20W, laser beam diameter: 200μm, scanning distance: 200μm, scanning rate: 2000mm / s), start scanning layer by layer. The obtained pellets were transferred to a cold isostatic press, and the applied pressure was 300 MPa, and the pressure was maintained for 30 minutes to obtain relatively dense pellets. Then the pellets are moved into a resistance furnace for debinding treatment. After cooling, they are sintered in a high-temperature furnace at a sintering temperature of 850°C and a holding time of 2 hours to obtain Li 2 TiO 3 Ball entity.

[0038] The compactness of the pellet body prepared in this example was measured by the Archimedes drainage method to be 78.1%; the crush strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com