Ligand-free atom transfer radical polymerization method under action of alkali

A technology of atom transfer and polymerization method, applied in the field of atom transfer radical polymerization and ligand-free atom transfer radical polymerization, can solve the problems of high toxicity, reduce the degree of environmental damage, reaction cost and high price, and reduce the reaction cost. , reduce the redox potential and accelerate the generation of active free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

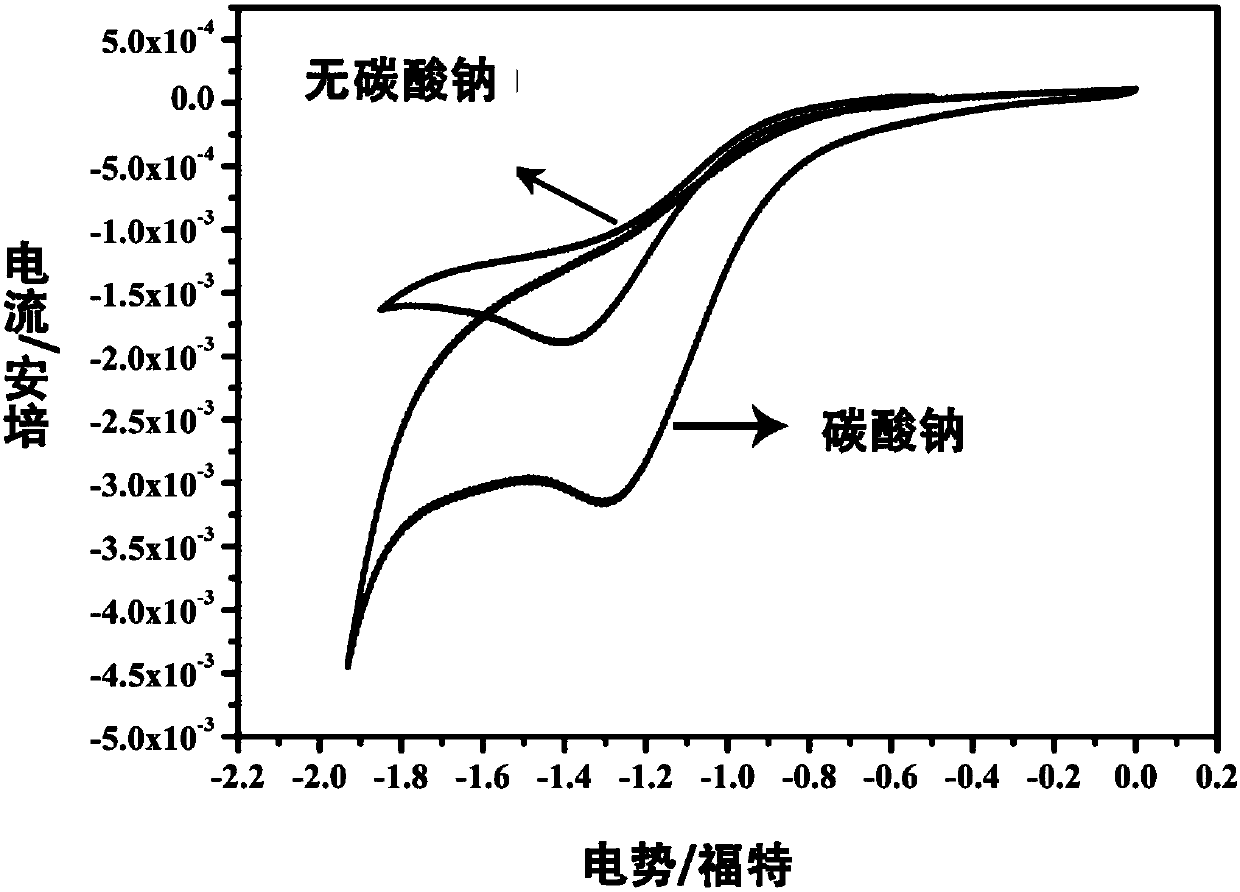

Method used

Image

Examples

Embodiment 1

[0048] After purifying methyl methacrylate monomer, solvent (solvent is respectively toluene, benzene, tetrahydrofuran, anisole, diphenyl ether, ethyl acetate), 2-bromo ethyl isobutyrate initiator and sodium phosphate, carry out Preparation of polymerization reaction components, methyl methacrylate, ethyl 2-bromoisobutyrate, ferrous bromide (low-valence transition metal catalyst) and sodium phosphate molar ratio of 200:1:1:2, methacrylic acid The volume ratio of methyl ester and solvent is 1:1. The preparation process is: take 0.061 gram of ferrous bromide and 0.0928 gram of sodium phosphate in the glove box and put them into the eggplant-shaped bottle, get 6 milliliters of methyl methacrylate monomer and 6 milliliters of solvent into the eggplant-shaped bottle, and magnetically After stirring for 20 minutes, 37.7 microliters of ethyl 2-bromoisobutyrate was added, and stirring was continued for 2 minutes to obtain a pre-reaction mixture.

[0049] Transfer the pre-reaction mix...

Embodiment 2

[0051] After purifying methyl methacrylate monomer, ethyl 2-bromophenylacetate initiator, sodium bicarbonate and stannous octoate, carry out reduction polymerization reaction component preparation (wherein stannous octoate is used as reducing agent), methyl The molar ratio of methyl acrylate, ethyl 2-bromophenylacetate, ferric bromide (or ferric chloride) (high valence transition metal catalyst), sodium carbonate and stannous octoate is 200:1:1:2:3. The preparation process is: take by weighing 0.0459 gram of ferric bromide (or ferric chloride) and 0.0476 gram of sodium bicarbonate in the glove box and put it into an eggplant-shaped bottle, get 6 milliliters of methyl methacrylate monomer and 0.275 milliliters of stannous octoate Add it into an eggplant-shaped flask, stir it magnetically for 20 minutes, then add 49.5 microliters of ethyl 2-bromophenylacetate, and continue stirring for 2 minutes to obtain a pre-reaction mixture.

[0052] Transfer the pre-reaction mixture in the ...

Embodiment 3

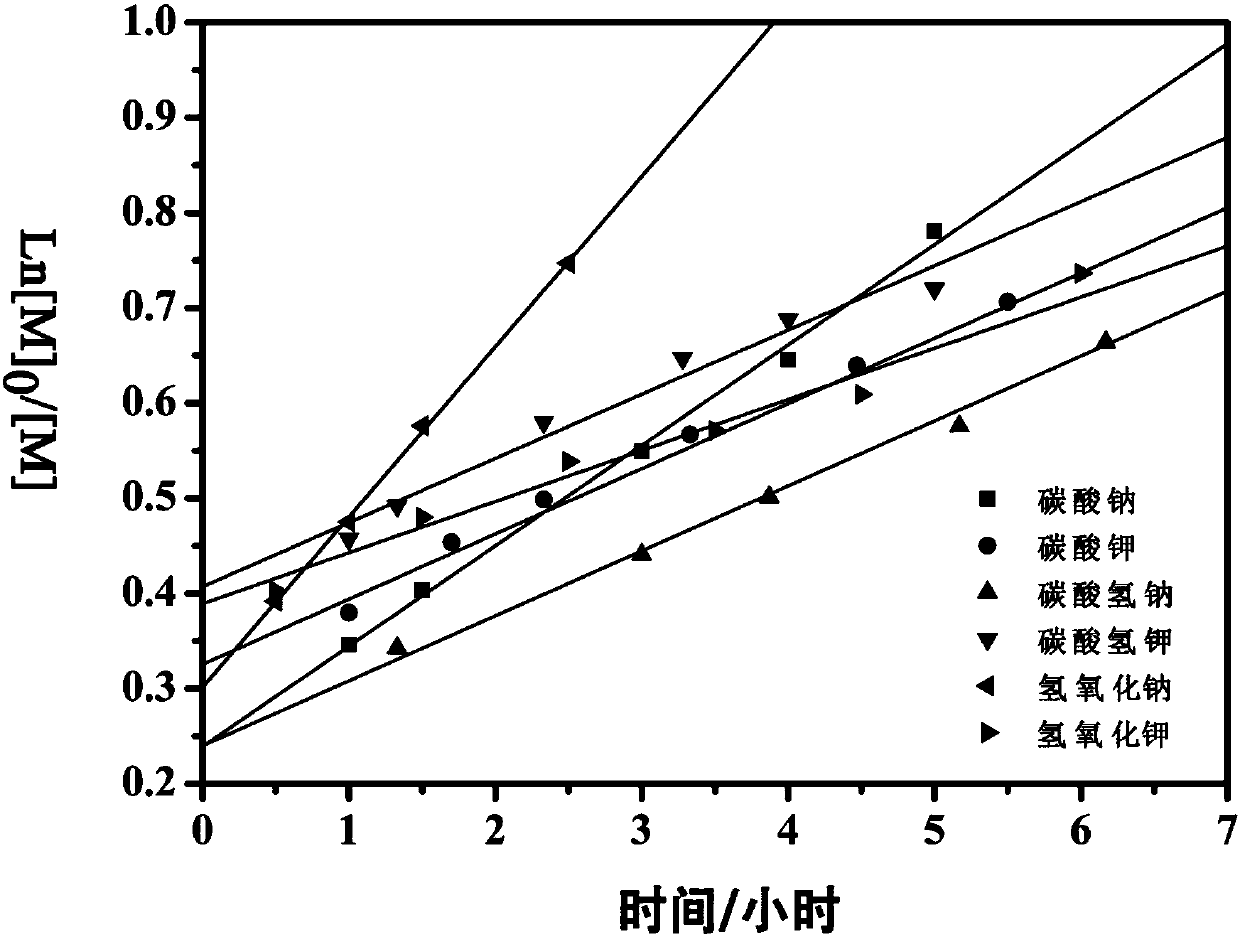

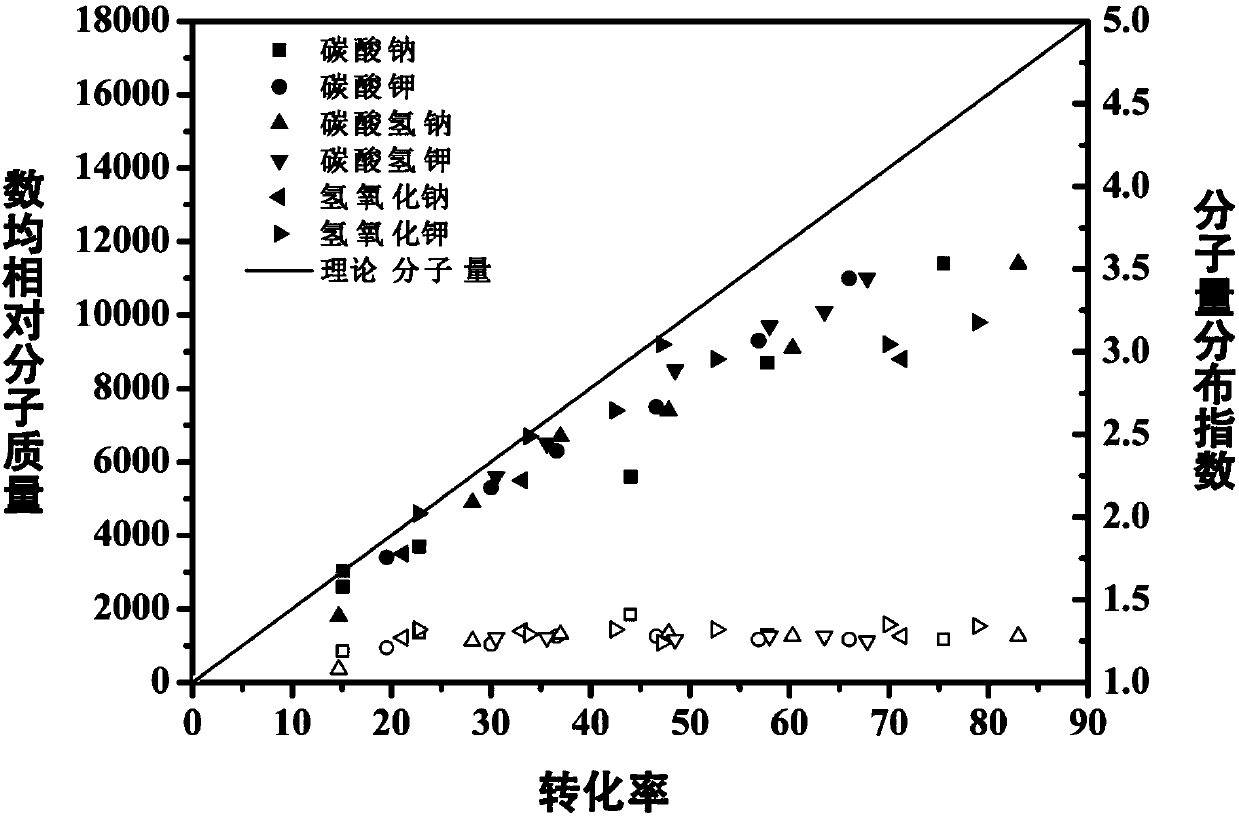

[0055] After purifying methyl methacrylate monomer, ethyl 2-bromophenylacetate initiator and sodium carbonate, prepare the polymerization reaction components, methyl methacrylate, ethyl 2-bromophenylacetate, ethylene bromide The molar ratio of iron (low-valence transition metal catalyst) to alkali is 200:1:1:2. The preparation process is: take 0.061 gram of ferrous bromide and a corresponding amount of alkali in the glove box and put it into an eggplant-shaped bottle, get 6 milliliters of methyl methacrylate monomer and add it into the eggplant-shaped bottle, and after magnetic stirring for 20 minutes, Then 49.5 microliters of ethyl 2-bromophenylacetate was added, and stirring was continued for 2 minutes to obtain a pre-reaction mixture.

[0056] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C; after the polymerization reaction reaches the predetermined reaction time interval, take a certain am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com