Multi-phase pipe type cyclone reactor capable of accurately regulating and controlling cyclone flow speed of liquid phase

A technology of tubular reactor and swirl tube, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large reaction tubes, increased equipment investment and operating costs, and low production efficiency, so as to speed up the reaction The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

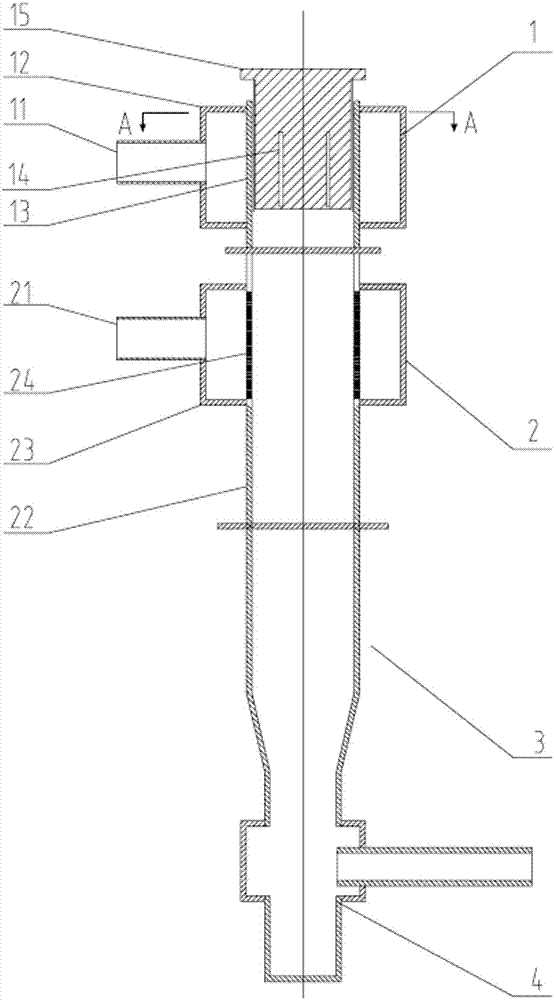

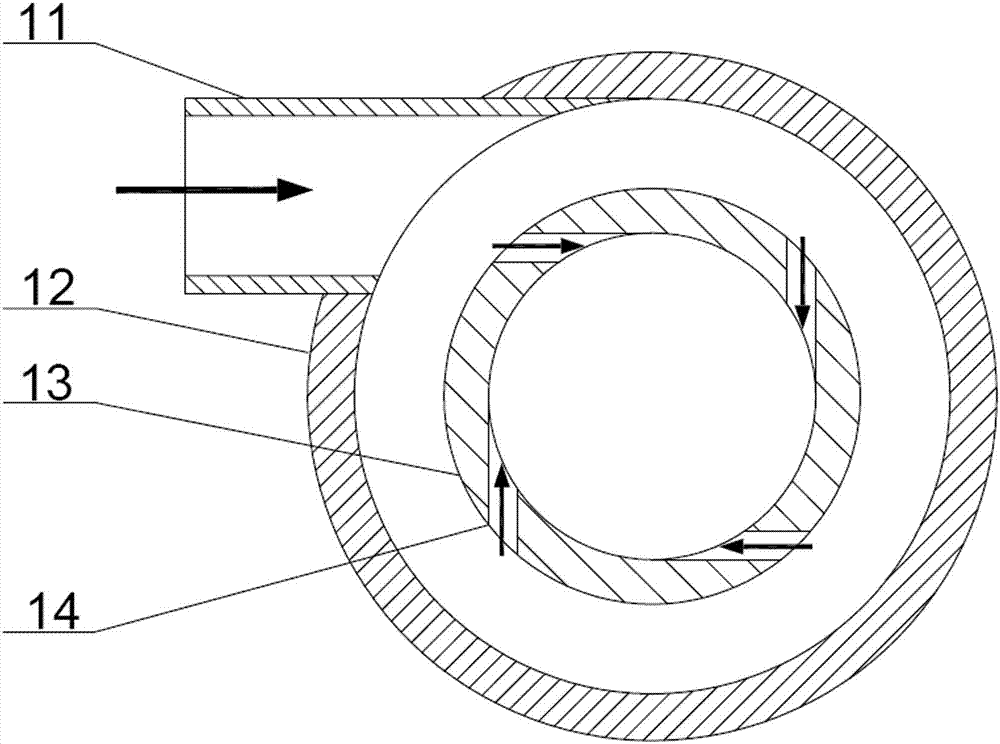

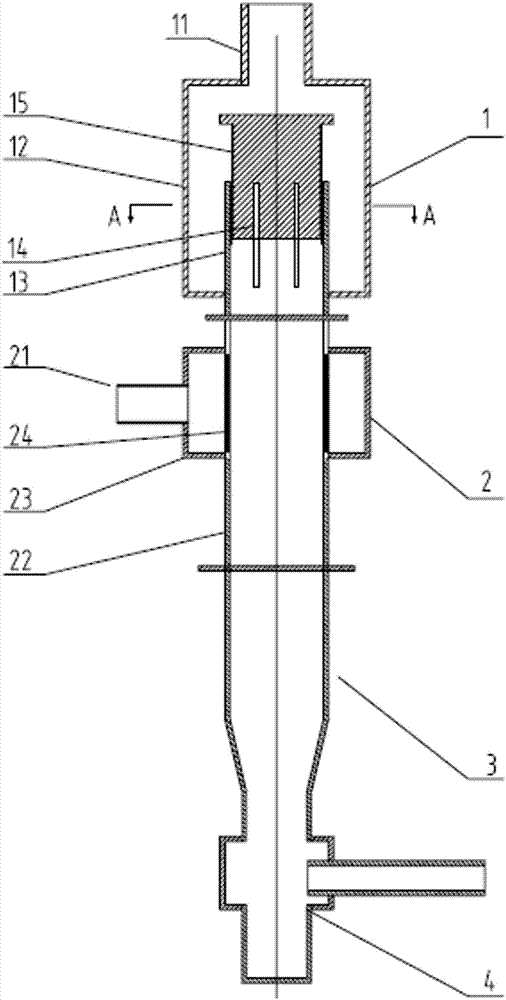

[0019] like Figure 1-4 As shown, the multiphase tubular cyclone reactor for accurately adjusting and controlling the flow rate of the liquid phase cyclone includes: a flow rate regulating cyclone 1 , a gas phase ejector 2 , a tubular reactor 3 and a discharge control valve 4 . The lower end of the swirl tube 13 in the flow rate regulating swirler 1 is connected with the upper end of the injector swirl tube 22 in the gas phase injector by flange, welding or screws; the injector of the gas phase injector 2 The lower end of the swirl tube 22 is connected to the upper end of the reaction tube of the tubular reactor 3 by flanges, welding or screws; the discharge control valve 4 is installed at the end of the reaction tube of the tubular reactor 3 ; The swirl tube 13 of the cyclone, the swirl tube 22 of the injector and the reaction tube of the tubular reactor 3 have the same inner diameter and are installed on the same axis.

[0020] Further, the flow rate regulating cyclone 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com