Method for producing lithium iron phosphate by solid-phase sintering of pure liquid-phase mixture

A technology of lithium iron phosphate and solid-phase sintering, which is applied in chemical instruments and methods, structural parts, phosphorus compounds, etc., can solve potential safety hazards of equipment and production personnel, fail to achieve the effect of pure liquid phase mixing, and shorten the synthesis time and other problems to achieve the effect of saving the grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] LiFePO cathode material for lithium ion battery 4 The preparation method is carried out in sequence according to the following steps:

[0038] Weigh out 0.5 mol FeSO 4 ·7H 2 O, 0.5mol H 3 PO 4 (85%), 0.5mol LiOH·H 2 O (99%) and 0.5mol ascorbic acid were added to a mixed solution of 150mL of water, stirred and mixed with argon gas; The solution is spray-dried to obtain uniformly mixed solid powder, and then according to the traditional solid-phase sintering method, that is, adding a carbon source material, grinding and sintering to obtain a lithium iron phosphate positive electrode material.

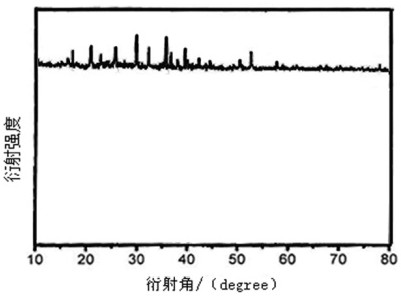

[0039] Depend on figure 1 The analysis shows that the peak positions in the spectrum correspond to the peaks of the lithium iron phosphate standard card (No. 40-1499) one by one, and no obvious impurity peaks appear, indicating that the obtained powder is a single olivine crystal structure. It can be seen that the synthesized LiFePO is pure phase 4 .

Embodiment 2

[0041] Weigh 0.05mol FeSO respectively 4 ·7H 2 O, 0.05mol H 3 PO 4 (85%), 0.05mol Li 2 CO 3 , 0.05mol of ascorbic acid was added to the solution of 150 mL of water, stirred and mixed while passing argon; after all dissolved, 0.1mol of ammonia water, a sulfate scavenger, was added, and the solution was fully mixed and stirred, and then the obtained solution was spray-dried to obtain a mixed solution. Then, according to the traditional solid-phase sintering method, that is, adding a carbon source material, grinding and sintering to obtain a lithium iron phosphate positive electrode material.

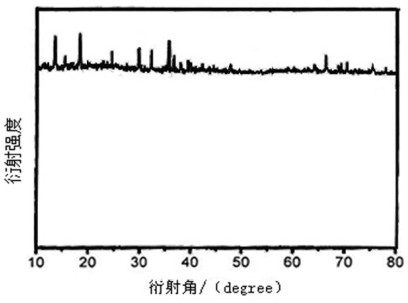

[0042] Depend on figure 2 The analysis shows that the peak positions in the spectrum correspond to the peaks of the lithium iron phosphate standard card (No. 40-1499) one by one, and no obvious impurity peaks appear, indicating that the obtained powder is a single olivine crystal structure. It can be seen that the synthesized LiFePO is pure phase 4 .

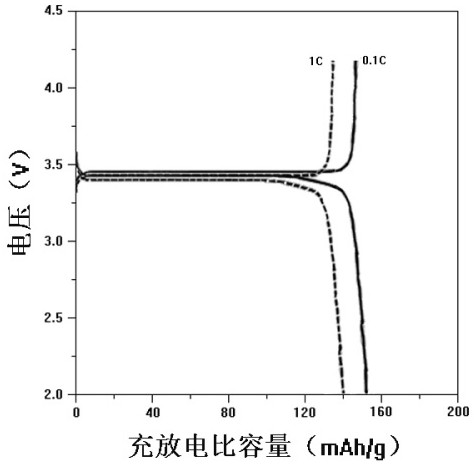

[0043] The obtained material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com