Dispersant modified nano zero-valent iron and preparing method and application thereof

A nano-zero-valent iron and dispersant technology, applied in the direction of nanotechnology, to achieve the effect of simple operation, high reactivity, and improved mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

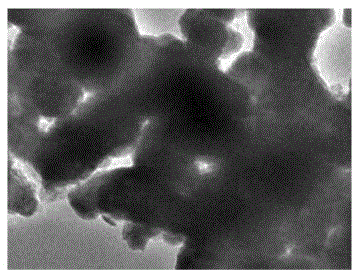

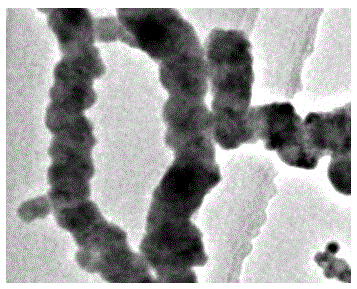

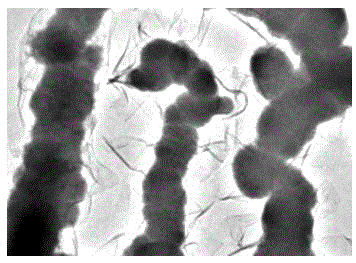

[0033] Example 1: Preparation of modified nano-zero-valent iron and ordinary unmodified nano-zero-valent iron and their transmission electron microscope characterization

[0034] (1) Preparation of MEHQ modified iron nanoparticles

[0035] Take 10 mL of MEHQ ethanol solution with a concentration of 1 g / L and mix it with 100 mL of a 0.5 mol / L FeSO4 solution, stir for 30 min, and add 1 mol / L KBH dropwise to the above mixed solution 4 The solution was 150mL and stirred. After the dropwise addition, delay stirring for 5min until the reaction was complete. The reacted solution was filtered with a Buchner funnel equipped with a 0.22 micron water-based microporous membrane, washed 3 times with deionized water, and suction filtered. until dry, move the obtained particles into 100mL of absolute ethanol and stir for 10min, then filter with a sand core filter device, after filtration, wash with absolute ethanol for 3 times, acetone for 1 time, and dry the obtained nanometer zero-valent ...

Embodiment 2

[0041] Example 2: Preparation and infrared spectrogram characterization of modified nano-zero-valent iron and ordinary unmodified nano-zero-valent iron

[0042] (1) Preparation of MEHQ modified iron nanoparticles

[0043] Take 10mL of MEHQ ethanol solution with a concentration of 7g / L and 100mL with a concentration of 0.5mol / LFeSO 4 After the solution is mixed, stir for 30min, add 1mol / LKBH dropwise to the above mixed solution 4 Add the solution to 150mL and stir. After the dropwise addition, delay stirring for 10min until the reaction is complete. Filter the reacted solution with a Buchner funnel equipped with a 0.22 micron water-based microporous filter membrane, wash it twice with deionized water, and pump Filter until dry, move the obtained particles into 100mL of absolute ethanol and stir for 5min, then filter with a sand core filter device, after filtration, wash twice with absolute ethanol and twice with acetone, and dry the obtained nano zero The valence iron particl...

Embodiment 3

[0049] Example 3: Preparation of MEHQ-modified nano-iron particles and PEI-modified nano-iron particles and their removal of hexavalent chromium

[0050] (1) Preparation of MEHQ modified nano-iron particles and its removal effect on hexavalent chromium (Cr(VI))

[0051] Take 10mL of MEHQ ethanol solution with a concentration of 3g / L and 150mL with a concentration of 1mol / LFeSO 4 After the solution is mixed, stir for 30min, add 0.5mol / LKBH dropwise to the above mixed solution 4 Add the solution to 200mL and stir. After the dropwise addition, delay stirring for 8min until the reaction is complete. Filter the reacted solution with a Buchner funnel equipped with a 0.22 micron water-based microporous filter membrane, wash it with deionized water for 3 times, and pump Filter until dry, move the obtained particles into 100mL of absolute ethanol and stir for 8min, then filter with a sand core filter device, after filtration, wash with absolute ethanol for 3 times, acetone for 2 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com