A kind of preparation method of rice starch-based fat substitute

A fat substitute, rice starch technology, applied in food preparation, food science, application, etc., can solve the problems of long production time, serious energy consumption, low yield of maltodextrin, etc., to improve efficiency, improve quality, DE small value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

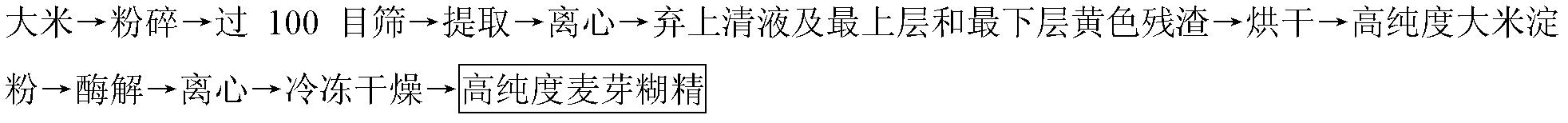

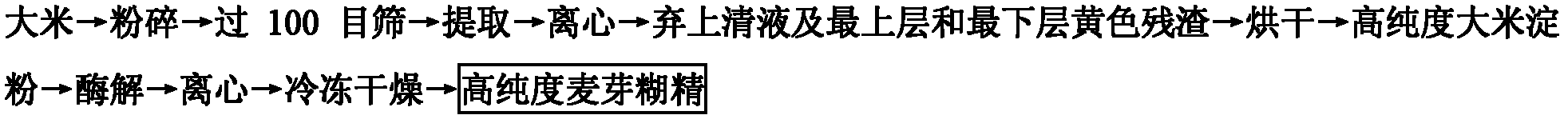

Method used

Image

Examples

Embodiment 1

[0019] Soak 1000 grams of fine rice after passing through a 100-mesh sieve with 7 liters of 0.05mol / L sodium hydroxide solution while stirring and extracting for 4 hours, centrifuge the rice starch, and remove the uppermost and lowermost residues after repeated centrifugation. Mix liquid and water according to the mass percentage of 1:5, add amylase, so that the mass fraction of amylase in the slurry is 1.5%, enzymolyze at 85 degrees for 10 minutes, centrifuge at 3500 rpm for 10 minutes, and take the supernatant at low temperature Freeze-drying is carried out after complete freezing to obtain maltodextrin, and the DE value of the obtained maltodextrin is 4.5.

Embodiment 2

[0021] Soak 5000 grams of fine rice after passing through a 120-mesh sieve with 5 liters of 0.1mol / L sodium hydroxide solution while stirring and extracting for 3 hours, centrifuge the rice starch, and remove the uppermost and lowermost residues after repeated centrifugation. Mix liquid and water according to the mass percentage of 1:4, add amylase, so that the mass fraction of amylase in the slurry is 0.5%, enzymolyze at 95 degrees for 12 minutes, centrifuge at 3500 rpm for 12 minutes, and take the supernatant at low temperature Freeze-drying is carried out after complete freezing to obtain maltodextrin, and the DE value of the obtained maltodextrin is 5.

Embodiment 3

[0023] Soak 5000 grams of fine rice after passing through an 80-mesh sieve with 6 liters of 0.08mol / L sodium hydroxide solution while stirring and extracting for 3 hours, centrifuge the rice starch, and remove the uppermost and lowermost residues after repeated centrifugation. Mix liquid and water according to the mass percentage of 1:6, add amylase so that the mass fraction of amylase in the slurry is 1%, enzymolyze at 95 degrees for 15 minutes, centrifuge at 3500 rpm for 8 minutes, and take the supernatant The maltodextrin was obtained by freeze-drying after complete freezing at low temperature, and the DE value of the obtained maltodextrin was 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com