Method for preparing modified nanosilicon dioxide

A nano-silica, modification technology, applied in the field of nano-materials, can solve the problems of poor dispersion of nano-silica, unfavorable industrialization, environmental pollution, etc., and achieve the effect of good dispersion, not easy to agglomerate, and enhance hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

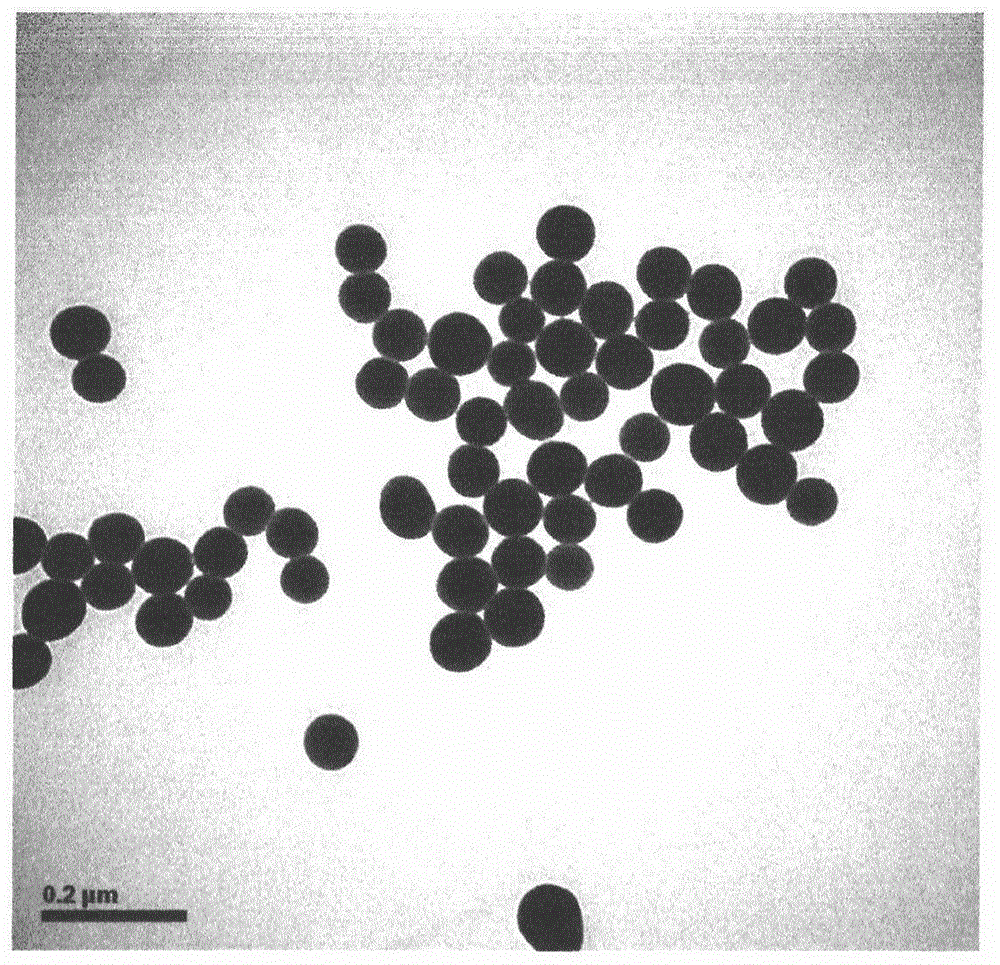

[0020] The embodiment of the present invention discloses a preparation method of modified nano silicon dioxide, comprising the following steps: step a) mixing cyclohexane, phenylethylphenol polyoxypropylene polyoxyethylene ether, n-hexanol and polyglycerol oleate , obtain a microemulsion system after stirring; step b) add deionized water, 1-2 mass parts of chitosan and 2-6 mass parts of ethyl orthosilicate to the microemulsion system in turn, stir, drop by drop Ammonia, add disodium edetate, add acetone after stirring, then add 1,2 propylene glycol and deionized water for washing to obtain nano silicon dioxide; step c) 2-8 parts by mass of the nano silicon dioxide obtained in step b Silicon oxide is added to the mixed solution of deionized water and ethanol, after stirring, 5-8 mass parts of polyethylene glycol are added, and the stirring is continued, and 1-2 mass parts of methacrylic acid oxypropylmethyldimethoxy Silane, to obtain a mixed solution after the reaction; step d)...

Embodiment 1

[0050] The invention provides a kind of preparation method of nano silicon dioxide, comprises the following steps:

[0051] 1. Mix 120 mass parts of cyclohexane, 20 mass parts of phenylethylphenol polyoxypropylene polyoxyethylene ether, 20 mass parts of n-hexanol, and 12 mass parts of polyglycerol oleate, stir for 15 minutes, It is a microemulsion system.

[0052] 2. Add 5 parts by mass of deionized water and stir for 10 minutes.

[0053] 3. Add 1 mass part of chitosan and 56 mass parts of tetraethyl orthosilicate, and stir for 10 minutes.

[0054] 4. Add 3 parts by mass of ammonia water dropwise, add 1 part by mass of disodium edetate and stir at room temperature for 1-2 hours.

[0055] 5. Add 80 parts by mass of acetone to break the emulsion to precipitate the nanospheres, and add 5 parts by mass of 1,2 propylene glycol for ultrasonic treatment. Then add a certain amount of deionized water and ethanol to repeatedly centrifuge and wash several times.

[0056] 6. The above...

Embodiment 2

[0062] 1. Mix 100 mass parts of cyclohexane, 12 mass parts of phenylethylphenol polyoxypropylene polyoxyethylene ether, 25 mass parts of n-hexanol, and 10 mass parts of polyglycerol oleate, stir for 15 minutes, It is a microemulsion system.

[0063] 2. Add 3 parts by mass of deionized water and stir for 18 minutes.

[0064] 3. Add 1 mass part of chitosan and 6 mass parts of tetraethyl orthosilicate, and stir for 6 minutes.

[0065] 4. Add 2 parts by mass of ammonia water dropwise, add 1 part by mass of disodium edetate and stir at room temperature for 1 hour.

[0066] 5. Add 60 parts by mass of acetone to break the emulsion to precipitate the nanospheres, and add 10 parts by mass of 1,2 propylene glycol for ultrasonic treatment. Then add a certain amount of deionized water and ethanol to repeatedly centrifuge and wash several times.

[0067] 6. Add 2-8 parts by mass of the above-mentioned nano silicon dioxide to the mixed solution of 100 parts by mass of deionized water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com