Preparation method of 3,3-bi(nitrine methyl) epoxybutane and tetrahydrofuran copolymer

A technology of butylene oxide and tetrahydrofuran, applied in 3 fields, achieves the effect of complete azidation reaction, simple method, and accelerated reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

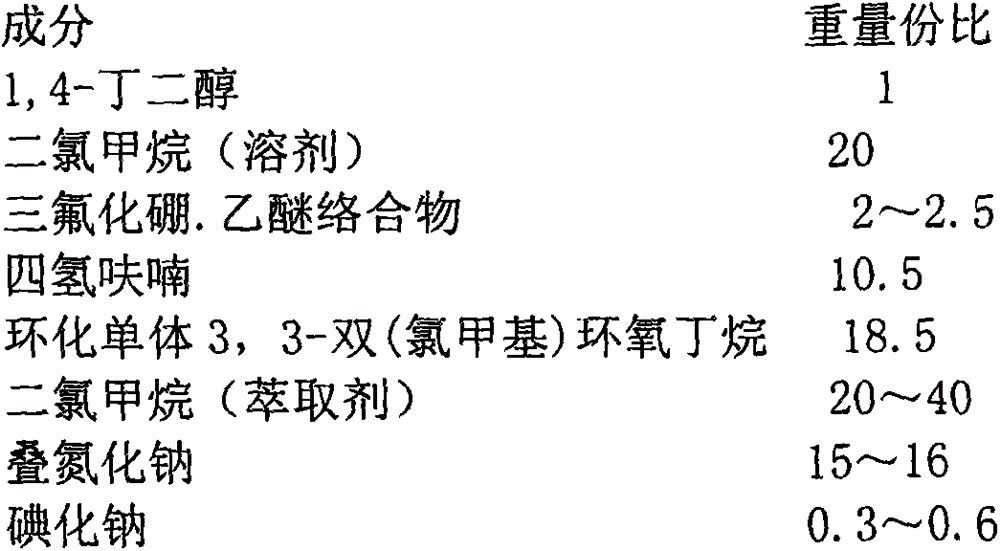

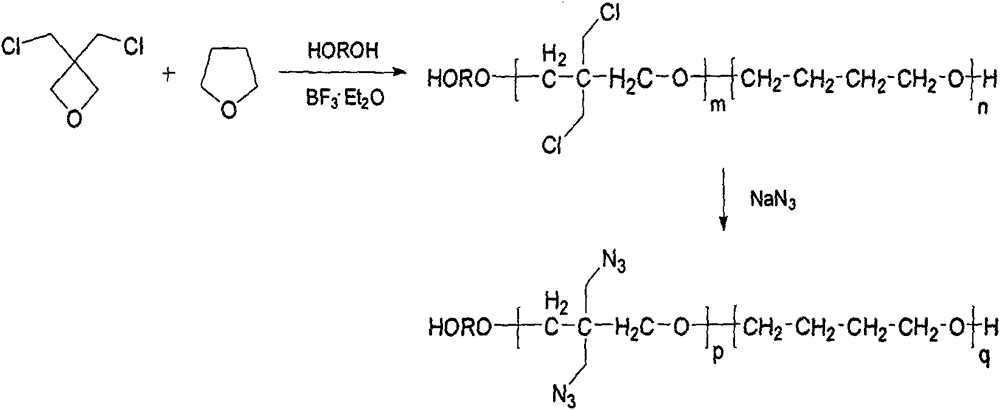

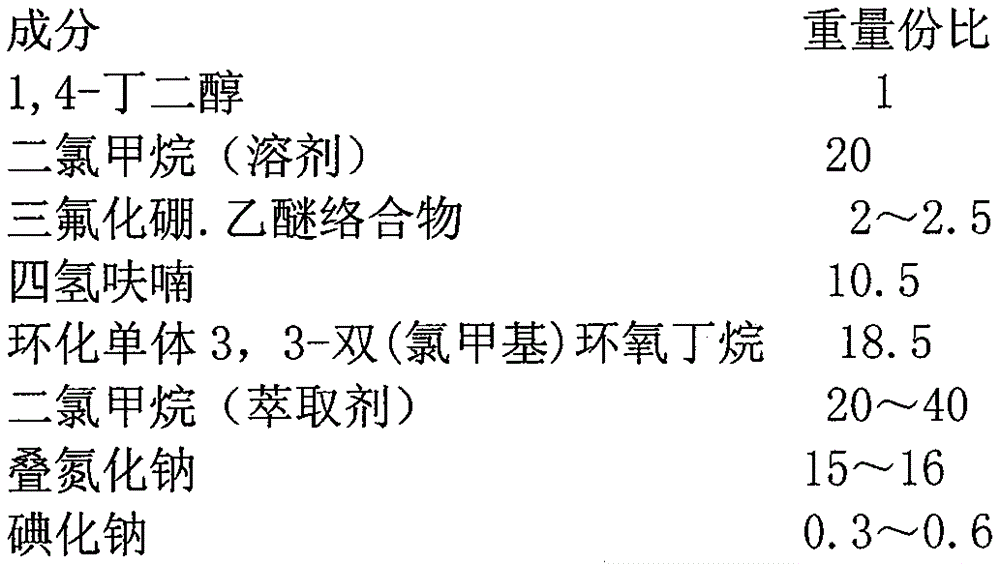

Method used

Image

Examples

example 1

[0016] Take a 500ml four-neck flask, equipped with mechanical stirring, constant pressure dropping funnel, low-temperature water bath, and thermometer, add 26g of dichloromethane, add 1.5g of 1,4-butanediol, 3.08g of boron trifluoride etherate complex, 13.6 g tetrahydrofuran, prepare the initiator at room temperature, lower the temperature to 0°C, add 24g of 3,3-bis(chloromethyl)butylene oxide dropwise within 1 to 2 hours, react at a temperature of 0±2°C for 12 hours, and then 50 g of dichloromethane was added for extraction, and 200 g of water was added for washing to obtain a copolymer of 3,3-bis(azidomethyl)butylene oxide and tetrahydrofuran.

[0017] Weigh 0.5g of sodium iodide, add 3,3-bis(azidomethyl)butylene oxide and tetrahydrofuran copolymer solution, add 20g of sodium azide at room temperature, react for 10 hours, add 200g of water After washing with water for 0.5 hour, the solvent was distilled off to obtain a copolymer of 3,3-bis(azidomethyl)butylene oxide and tetr...

example 2

[0019] Take: 1000ml four-necked flask equipped with mechanical stirring, constant pressure dropping funnel, low-temperature water bath, thermometer, add 52g of dichloroethane, add 2.6g of 1,4-butanediol, 6.1g of boron trifluoride etherate complex , 27.2g tetrahydrofuran, prepare the initiator at room temperature, cool down to -2°C, add 48g of 3,3-bis(chloromethyl)butylene oxide dropwise within 1 to 2 hours, and react at a temperature of 0±2°C for 18 hour, then through extraction and neutralization, 3,3-bis(chloromethyl)epoxybutylene tetrahydrofuran copolymer was obtained;

[0020] Weigh 1.5g of sodium iodide, add 3,3-bis(chloromethyl)butylene oxide tetrahydrofuran copolymer solution, add 40g of sodium azide at room temperature, react for 12 hours, add 200g of water and wash with water for 0.5 hours, the solvent was distilled off to obtain 3,3-bis(azidomethyl)epoxybutylene tetrahydrofuran copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com