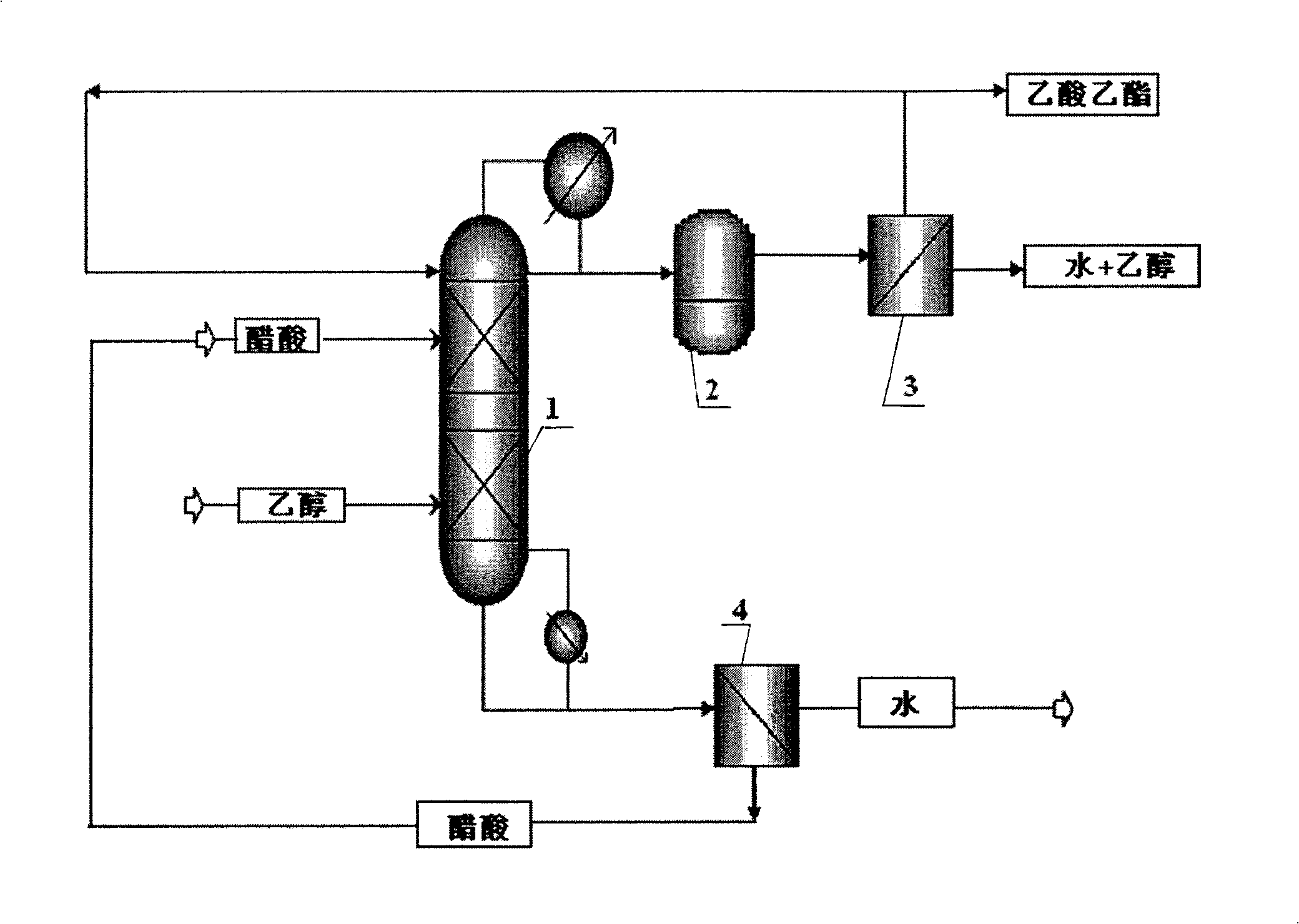

Method for producing ethyl acetate with coupled reaction distillation and permeation steam generation

A technology of pervaporation and reactive distillation, which is applied in the field of coupling reactive distillation and pervaporation to produce ethyl acetate, can solve the problems of poor reflux water carrying capacity, limited production capacity, large gas-liquid phase load, etc. The effect of reducing the volume and reducing the reflux ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Reactive distillation tower, the height of the reaction section is 50cm, the height of the rectification section and the stripping section is 40cm, and it is equipped with stainless steel θ ring packing and CT-450 solid acid catalyst. The raw materials acetic acid and ethanol are fed from the upper and lower parts of the tower respectively, and the feed flow rates are 0.8kg / h and 0.5kg / h respectively. The temperature at the bottom of the tower is controlled at 110°C, the temperature at the top of the tower is controlled at 70°C, the flow rate of the distillate at the top of the tower is 0.5kg / , and the reflux ratio in the tower is 1.5. The phase separator is equipped with an insulating layer, and the temperature is controlled at 60°C. After the top material is separated by a phase separator, the composition of the upper organic phase obtained is: water 7.5% (wt%); ethanol 0.5% (wt%); ethyl acetate 92% (wt%).

[0021] The pervaporation water-permeable membrane I is comp...

Embodiment 2

[0024] Reactive distillation tower, the height of the reaction section is 55cm, the height of the rectification section and the stripping section is 40cm, and Raschig ring packing is installed inside, and the catalyst is strong acidic cation exchange resin. Acetic acid and ethanol are fed from the upper and lower parts of the tower respectively, and the feed flow rates are 1.0kg / h and 0.5kg / h respectively. The temperature at the bottom of the tower is controlled at 110°C, the temperature at the top of the tower is controlled at 70°C, the flow rate of the output at the top of the tower is 0.5kg / h, and the reflux ratio in the tower is 2. The temperature of the phase separator is controlled at 50°C. After the top material is separated by a phase separator, the composition of the obtained upper organic phase is: water 5.3% (wt%), ethyl acetate 94.7% (wt%).

[0025] The pervaporation permeable membrane module II uses polyvinyl alcohol permeable membrane with polyacrylonitrile as t...

Embodiment 3

[0028] Reactive distillation tower, the height of the reaction section is 50cm, the height of the rectification section and the stripping section is 40cm, and the stainless steel θ ring packing is installed inside, and the catalyst is a solid acid catalyst. Acetic acid and ethanol are fed from the upper and lower parts of the tower respectively, and the feed rates are 0.8kg / h and 0.5kg / h respectively. The temperature at the bottom of the tower is controlled at 110°C, the temperature at the top of the tower is controlled at 70°C, the output rate of the top product is 0.5kg / h, and the reflux ratio in the tower is 1.5. The temperature of the phase separator is controlled at 60°C. After the top material is separated by a phase separator, the composition of the upper organic phase obtained is: water 7.5% (wt%); ethanol 0.5% (wt%); ethyl acetate 92% (wt%).

[0029] The pervaporation water-permeable membrane module I is composed of a ceramic support body and a chitosan organic layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com