Gypsum-containing construction material compounds

A technology of building materials, compounds, applied in the field of tile adhesives or self-leveling compounds, which can solve the problems of unsatisfactory mechanical strength, non-negligible hydrophilicity, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

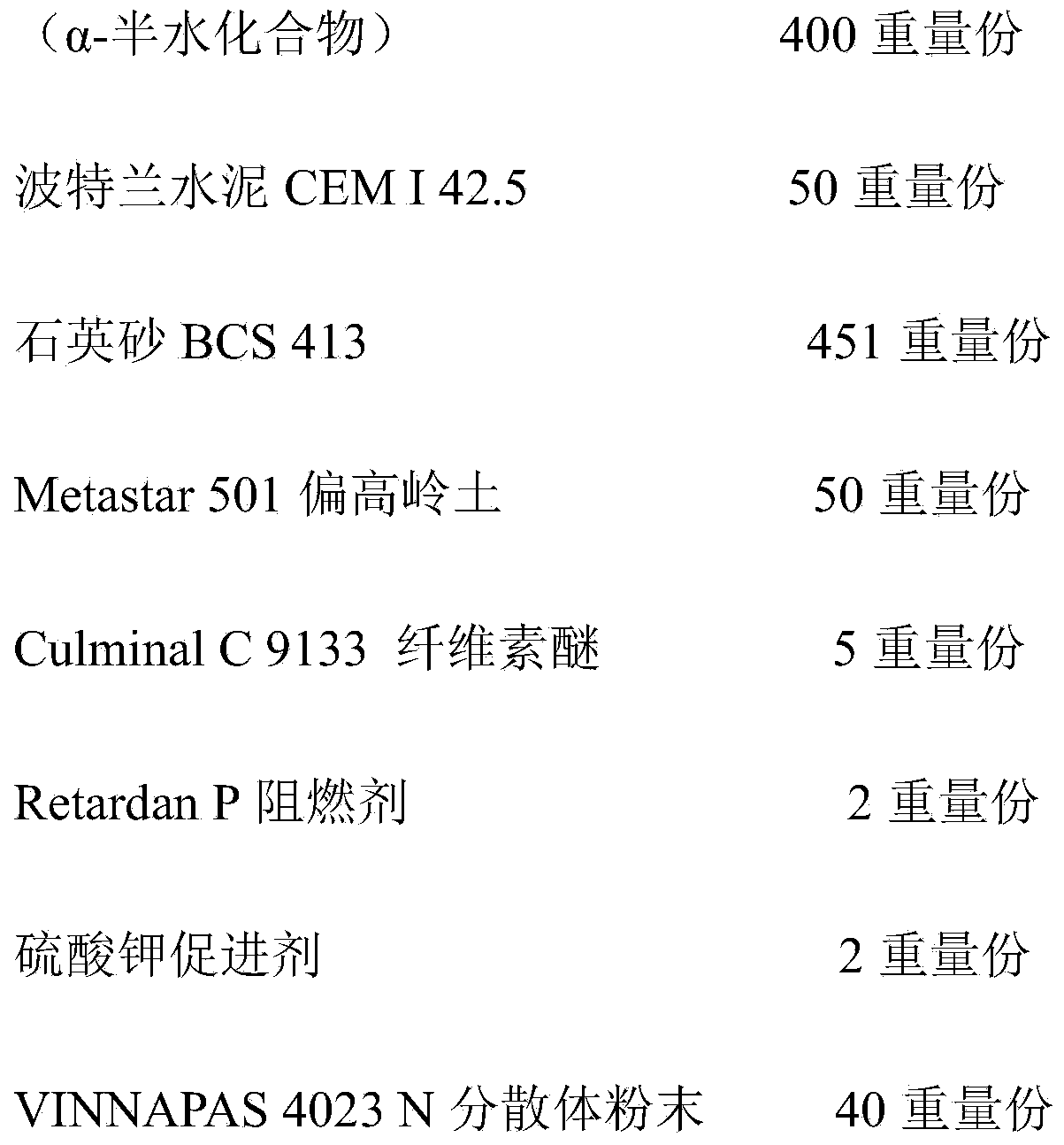

[0051] Recipe for tile adhesive:

[0052] Hard plaster in Paris HF1

[0053]

[0054] (polyvinyl alcohol stabilized water-redispersible dispersion powder based on a copolymer of vinyl acetate and ethylene)

[0055] Mixing water: Add 280ml water to 1000g dry mix.

example 2

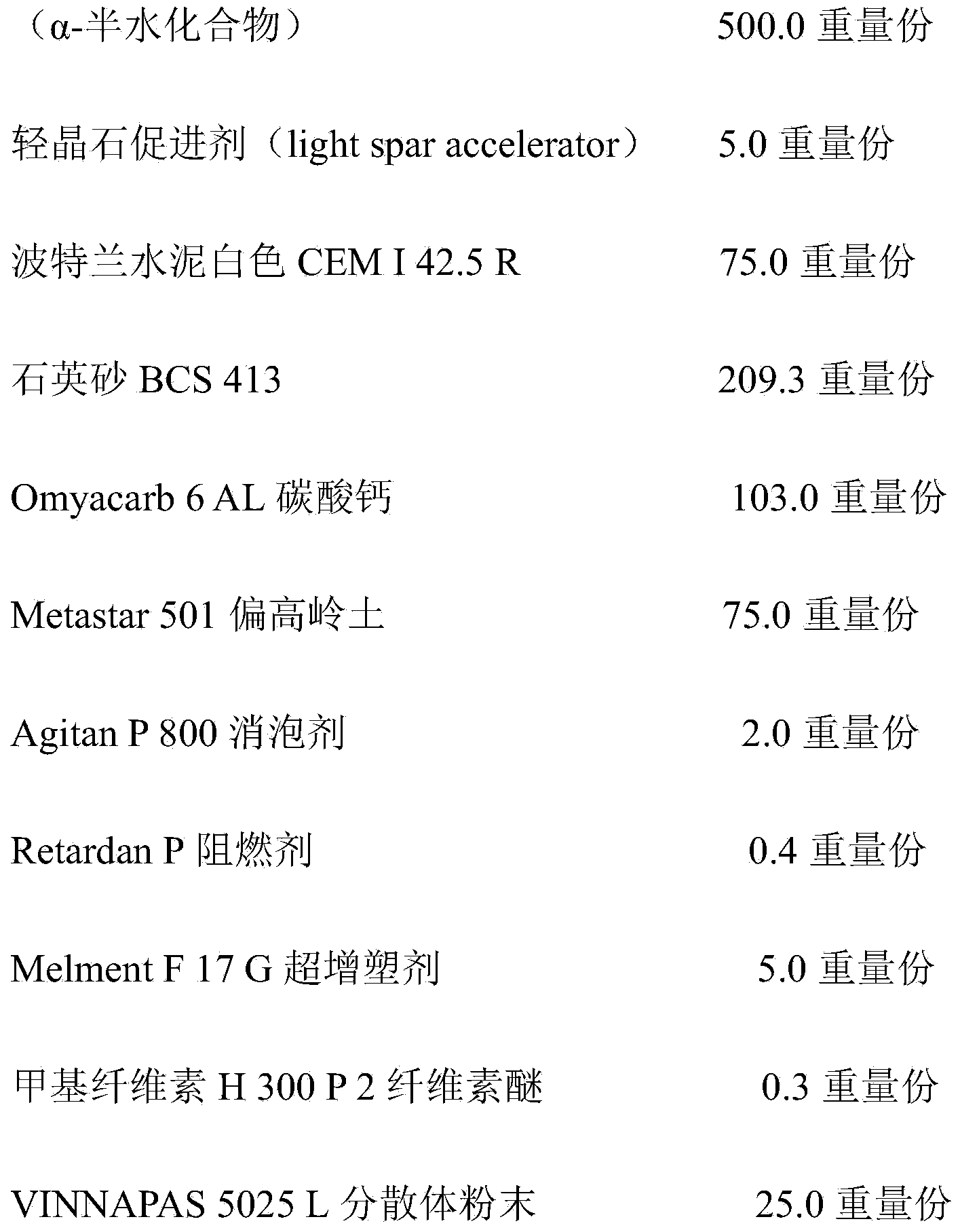

[0057] Recipe for floor filling compound:

[0058] Paris HF1 Hard Stucco

[0059]

[0060] (polyvinyl alcohol stabilized water-redispersible dispersion powder based on a copolymer of vinyl acetate and ethylene)

[0061] Mixing water: Add 280ml water to 1000g dry mix.

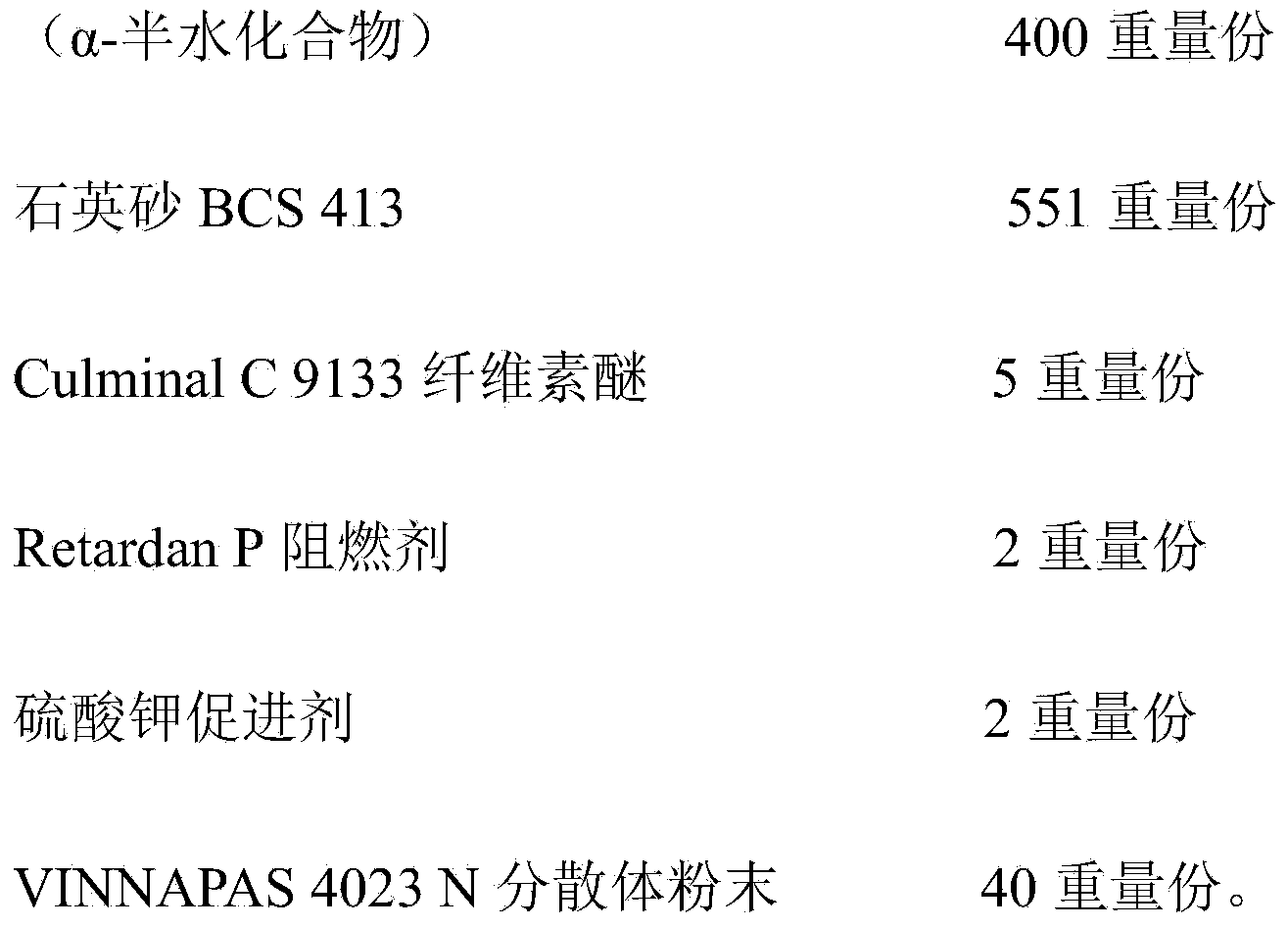

Embodiment 7

[0106] Similar to Example 1, the only difference is that the dry mixture is additionally mixed with 3 parts by weight of powdered potassium methyl silicate (silicate from Preparation Example 2 of WO2012 / 022544: the molar ratio of potassium to silicon = 0.64) mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com