High-tensile-strength composite rock wool plate, thermal insulation decorative plate with same as thermal insulation layer and reinforced waterproof function protection agent

A high tensile strength, rock wool board technology, applied in thermal insulation, building thermal insulation materials, coatings, etc., can solve the problems of chemical pollution of exterior walls, cumbersome construction techniques, and weak structures, and achieve firm structures and simple preparation processes , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

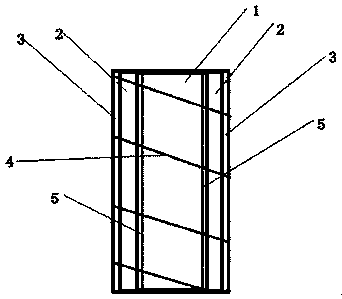

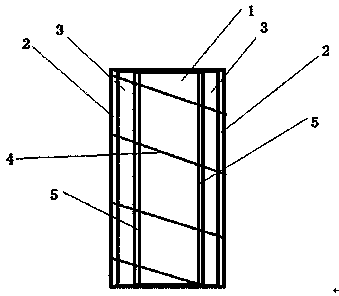

[0056] Such as figure 2 As shown, the high tensile strength composite rock wool board includes a rock wool board 1, at least one side of the rock wool board 1 is sequentially provided with an alkali-resistant mesh layer 5 and a penetrating adhesive layer 3, the rock wool board 1, and the alkali-resistant mesh layer 5 And the adhesive layer 3 forms a three-dimensional three-dimensional network reinforced structure layer through the suture line 4, and the three-dimensional three-dimensional network reinforced structure layer is provided with a reinforced and waterproof function protective adhesive protective agent layer 2. The protective agent layer is a mortar layer. The alkali-resistant mesh layer is a basalt fiber mesh cloth layer. Adhesive layer 3 is made from adhesive layer recipe 1.

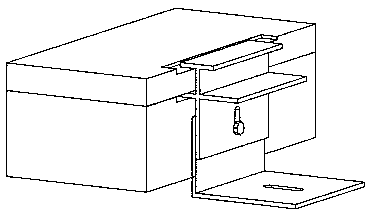

[0057] Such as image 3 As shown, the thermal insulation decorative board includes the thermal insulation layer and the decorative layer; wherein: the high tensile strength composite rock...

Embodiment 2

[0060] Such as figure 2 As shown, the high tensile strength composite rock wool board includes a rock wool board 1, at least one side of the rock wool board 1 is sequentially provided with an alkali-resistant mesh layer 5 and an adhesive layer 3, and the rock wool board 1, the alkali-resistant mesh layer 5 and the The adhesive layer 3 forms a three-dimensional mesh reinforced structure layer through the sutures 4, and the protective agent layer 2 is arranged outside the three-dimensional mesh reinforced structure layer. The protective agent layer is an emulsion layer. The alkali-resistant mesh layer is a glass fiber mesh cloth layer. Adhesive layer 3 was made from adhesive layer recipe 2.

Embodiment 3

[0062] Such as figure 2 As shown, the high tensile strength composite rock wool board includes a rock wool board 1, at least one side of the rock wool board 1 is sequentially provided with an alkali-resistant mesh layer 5 and an adhesive layer 3, and the rock wool board 1, the alkali-resistant mesh layer 5 and the The adhesive layer 3 forms a three-dimensional mesh reinforced structure layer through the sutures 4, and the protective agent layer 2 is arranged outside the three-dimensional mesh reinforced structure layer. The protective agent layer is a powder layer. The alkali-resistant mesh layer is a glass fiber mesh cloth layer. Adhesive layer 3 is made by adhesive layer recipe 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com