Pollution-free gas-phase oxidation separation purification method for artificial diamond

A synthetic diamond, gas-phase oxidation technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as environmental pollution of synthetic diamond powder, avoid harsh working conditions and serious environmental pollution, save raw materials, The effect of post-processing simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

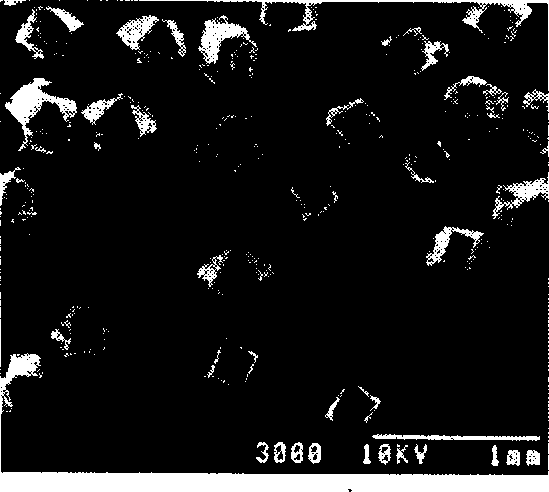

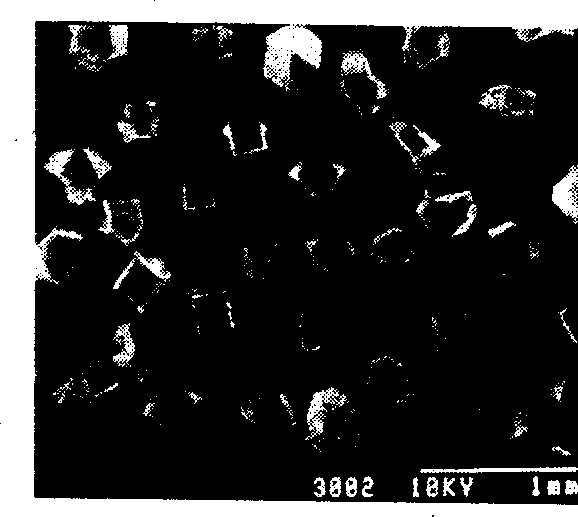

Image

Examples

Embodiment Construction

[0025] Adopt the step of processing method of the present invention to produce artificial diamond as follows:

[0026] The first step is primary crushing, using mechanical crushing methods to crush the synthetic rods into fine particles, such as jaw crushers or roller crushers. The fine particle diameter is preferably 3-5mm.

[0027] The second step: the pyrolysis process, using the high-temperature sintering method based on the principle of gas phase oxidation to pyrolyze the fine particles. Strictly control the pyrolysis temperature of 450°C-650°C, and use water vapor and inert gas for protection.

[0028] The third step: crushing and dissociation process, which further crushes and dissociates the fine particles treated by high temperature oxidation. Use mechanical rolling and rubbing as much as possible, such as ball milling. Strictly control the strength and add dielectric protection to prevent damage to the diamond single crystal.

[0029] The fourth step: Separation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com