Alkali-activating-agent-doped early strength super-high performance concrete and preparation method thereof

An alkali activator and ultra-high-performance technology, applied in the field of concrete, can solve the problems that restrict the large-scale production of ultra-high-performance concrete prefabricated components, long demolition time, and low early-stage strength of ultra-high-performance concrete. The effect of shortening the setting time, shortening the demoulding time, and compacting the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

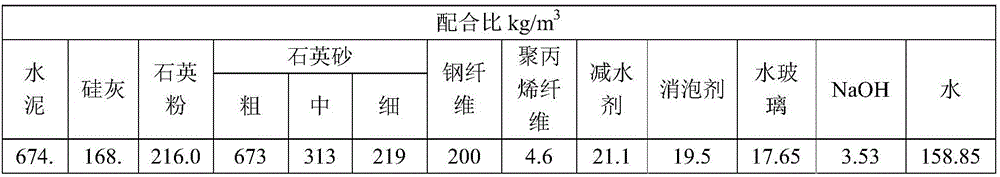

[0038] Cement: Shield Stone P.O42.5 Ordinary Portland Cement; Silica Fume: Commercially available SiO 2The content (mass content) is not less than 92%; quartz powder: commercially available 325 mesh; ~0.212mm (40~70 mesh), fine quartz sand 0.212~0.125mm (70~120 mesh); steel fiber: the length of Shanghai Bekaert No. 2 Steel is 13±10% mm, and the diameter is 0.2±0.03mm Steel fiber, tensile strength ≥ 2850Mpa, density 8000kg / m 3 . Polypropylene fiber: commercially available ordinary polypropylene fiber, the length is 6mm, the diameter is 0.031mm, and the density is 920kg / m 3 , length 6mm; water reducer: polycarboxylate water reducer, water reducing efficiency is 25%; defoamer: water-soluble defoamer; alkali activator: through the water glass solution (water content (mass) Percentage) 55%) is mixed with the NaOH of purity ≥ 99% to prepare the water glass solution that modulus is 1.4. The mix ratio of ultra-high performance concrete is shown in Table 1.

[0039] Table 1 Ultra-...

Embodiment 2

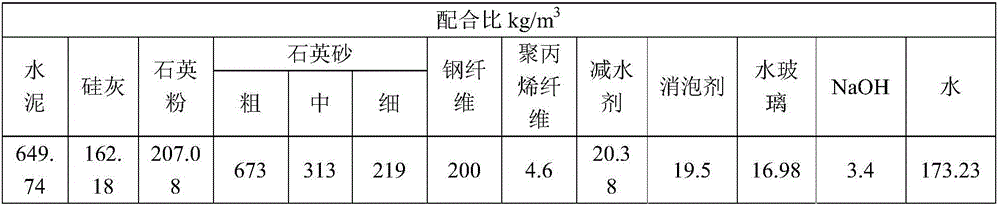

[0053] Cement: Shield Stone P.O42.5 Ordinary Portland Cement; Silica Fume: Commercially available SiO 2 The content is not less than 92%; quartz powder: commercially available 325 meshes; 40~70 mesh), fine quartz sand 0.212~0.125mm (70~120 mesh); steel fiber: steel fiber with a length of 13±10% mm and a diameter of 0.2±0.03mm produced by Shanghai Bekaert No. 8000kg / m 3 . Polypropylene fiber: commercially available ordinary polypropylene fiber, length 6mm, density 920kg / m 3 Water reducer: polycarboxylate water reducer, water reducing efficiency is 25%; Defoamer: water-soluble defoamer; Alkali activator: by the water glass solution (water content (mass percentage) 55 %) mixed with NaOH with a purity ≥99%. The mix ratio of ultra-high performance concrete is shown in Table 3.

[0054] Table 3 Ultra-high performance concrete mix ratio

[0055]

[0056] Weigh each raw material according to the mixing ratio and stir, and the stirring sequence is as follows:

[0057] Pour ce...

Embodiment 3

[0067] An early-strength ultra-high-performance concrete mixed with an alkali activator. The components of the concrete include 1019 parts of cementitious material, 1140 parts of quartz sand, 205 parts of fiber, 20.38 parts of water reducing agent, and 25.6 parts of defoaming agent in parts by mass. parts, 20.38 parts of base activator and 152.85 parts of water.

[0068] Wherein, the cementitious material includes 63.7% of cement, 15.9% of silica fume and 20.4% of quartz powder in terms of mass percentage; wherein the cement is not lower than P.O42.5 Portland cement, and SiO in silica fume 2 The mass content is not less than 92%; the particle size of quartz powder is not greater than 325 mesh.

[0069] The quartz sand includes coarse quartz sand, medium quartz sand and fine quartz sand with a mass ratio of 1:0.46:0.32, wherein the particle size of the coarse quartz sand is 0.850-0.425 mm, and the particle size of the medium quartz sand is 0.425 mm. ~0.212mm, the particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com