Phenolic lignin-based modified foaming phenolic resin, foamed plastic and preparation method of phenolic lignin-based modified foaming phenolic resin

A technology of phenolic lignin and phenolic resin, applied in the field of energy-saving thermal insulation materials, can solve the problems affecting the thermal conductivity, oxygen index foaming uniformity, weather resistance and dimensional stability, industrial utilization and industrialization development of phenolic resin foaming materials. It also solves the problems of long distance and uneven foaming, and achieves the effect of promoting industrial application process, fast curing rate and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

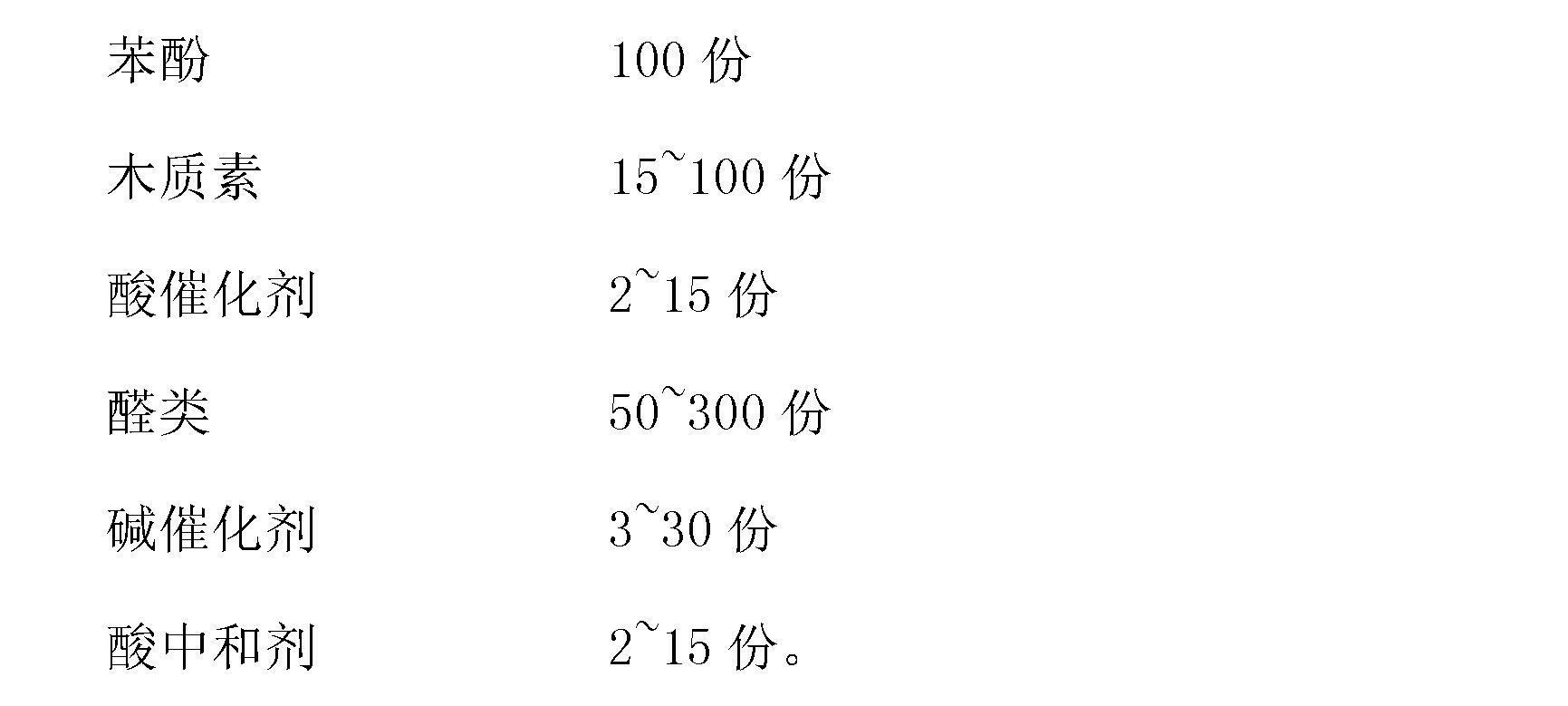

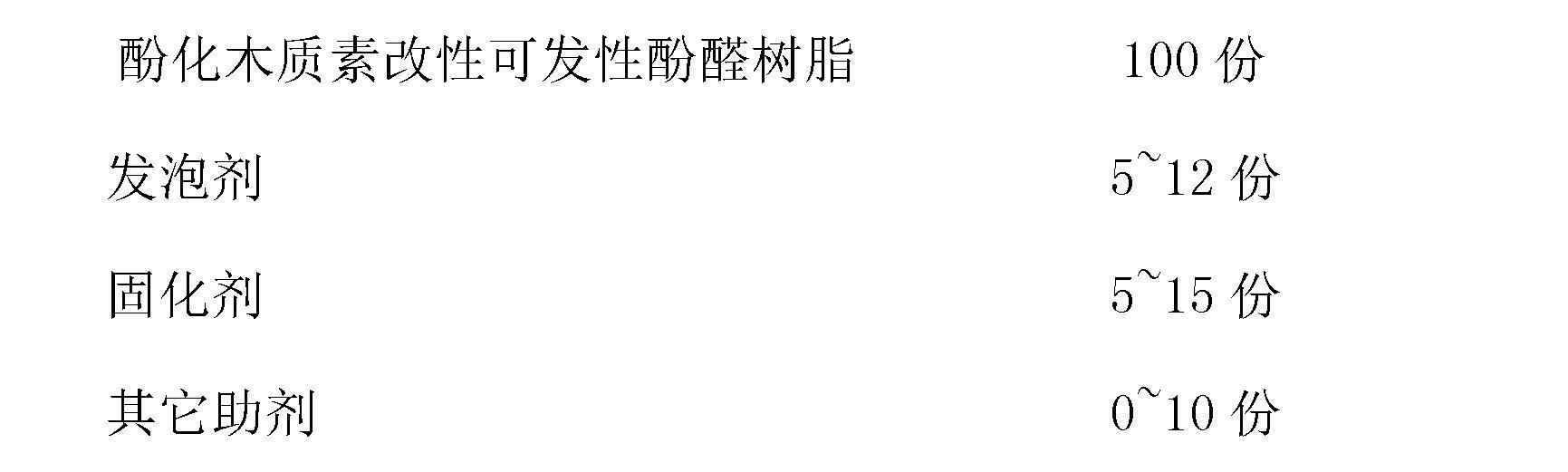

Method used

Image

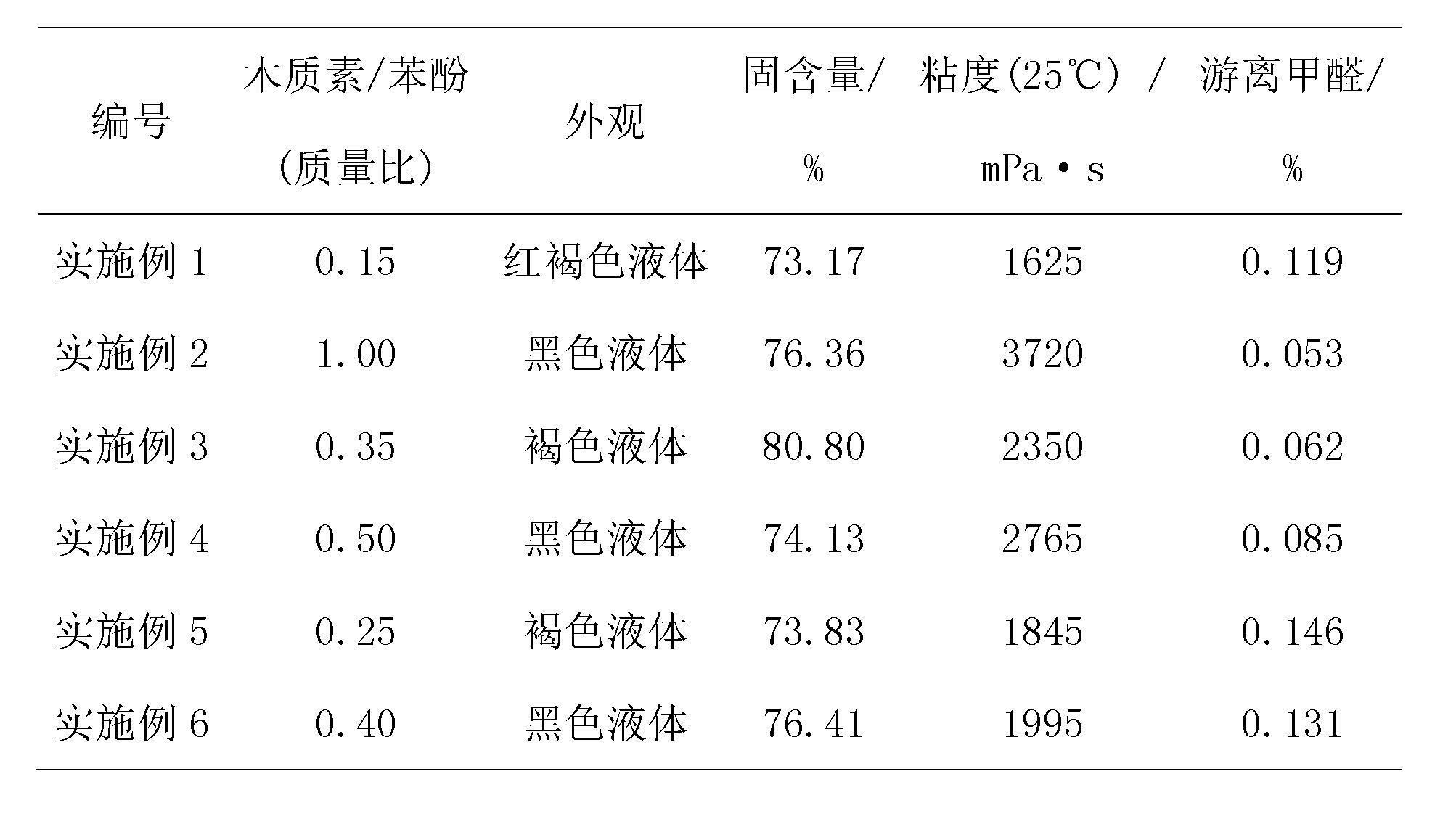

Examples

Embodiment 1

[0033]Add 100.0g of phenol into the four-neck flask, rapidly raise the temperature to 70°C, add 15.0g of magnesium lignosulfonate, 2.0g of concentrated hydrochloric acid with a weight concentration of 36%, raise the temperature to 120°C, cool down, and cool the liquefied liquid to 50°C ℃, add 30.0g of sodium hydroxide solution with a weight concentration of 10%, 44.0g of paraformaldehyde, after 15 minutes of self-reaction, heat up to 70℃, keep warm for 90min, add 29.8g of formaldehyde, after 15min of self-reaction, heat up to 92℃ Insulation reaction, when the temperature reaches 90°C, take a sample every 5 minutes, and measure the viscosity by the foam-inversion method. When the foam-inverting time reaches 12.0s (25°C), add 10.0g of water, start to cool down, and adjust with 6mol / L hydrochloric acid at the same time When the pH reaches 6.0-7.0, when the temperature drops to 50°C, the material is discharged, and the lignin phenolization liquid modified expandable phenolic resin ...

Embodiment 2

[0035] Add 100.0g of phenol into the four-neck flask, rapidly raise the temperature to 70°C, add 40.0g of sodium lignosulfonate, 14.0g of concentrated hydrochloric acid with a weight concentration of 36%, and 10.0g of water, raise the temperature to 100°C, keep it warm for 20min, and then Add 30.0g of sodium lignosulfonate, keep warm for 20min, then add 30.0g of sodium lignosulfonate, heat up to 120°C, keep warm for 20min, cool the liquefied solution to 50°C, add 43.7g of 40% sodium hydroxide solution, Formaldehyde 189.8g, after 15 minutes of self-reaction, heat up to 80°C, keep warm for 75min, add 51.7g of formaldehyde, after 15 minutes of self-reaction, heat up to 95°C and keep warm for reaction, when the temperature reaches 90°C, take a sample every 5min, use reverse foam Viscosity was measured by the method. When the time of pouring foam reached 4.0s (25°C), the temperature began to drop, and at the same time, the pH was adjusted to 6.0-7.0 with solid oxalic acid. When the ...

Embodiment 3

[0037] Add 100.0g of phenol into the four-necked flask, rapidly raise the temperature to 70°C, add 35.0g of sodium lignosulfonate, 5.9g of concentrated hydrochloric acid with a weight concentration of 36%, raise the temperature to 120°C, keep it warm for 20min, and cool the liquefied liquid to 50°C ℃, add 30.3g of 30% sodium hydroxide solution, 139.7g of formaldehyde, after 15 minutes of self-reaction, heat up to 75℃, keep warm for 75min, add 46.6g of formaldehyde, after 15min of self-reaction, heat up to 90℃ and keep warm for reaction, when the temperature After reaching 90°C, take a sample every 5 minutes, and measure the viscosity with the reverse foam method. When the reverse foam time reaches 4.8s (25°C), start to cool down, and at the same time adjust the pH to 6.0-7.0 with solid oxalic acid. When the temperature drops to 60°C 69.7g of water was removed in vacuum, and the material was discharged to obtain the lignin phenolization liquid modified expandable phenolic resin....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com