Method using pressure swing adsorption to purify hydrogen produced from anaerobic fermentation of kitchen garbage

A technology of food waste and pressure swing adsorption, which is applied in the direction of chemical instruments and methods, separation methods, hydrogen separation, etc., can solve the problems of high energy consumption, large investment, and complicated operation of cryogenic separation technology, and achieve convenient operation, The effect of simple system structure and broad technical application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

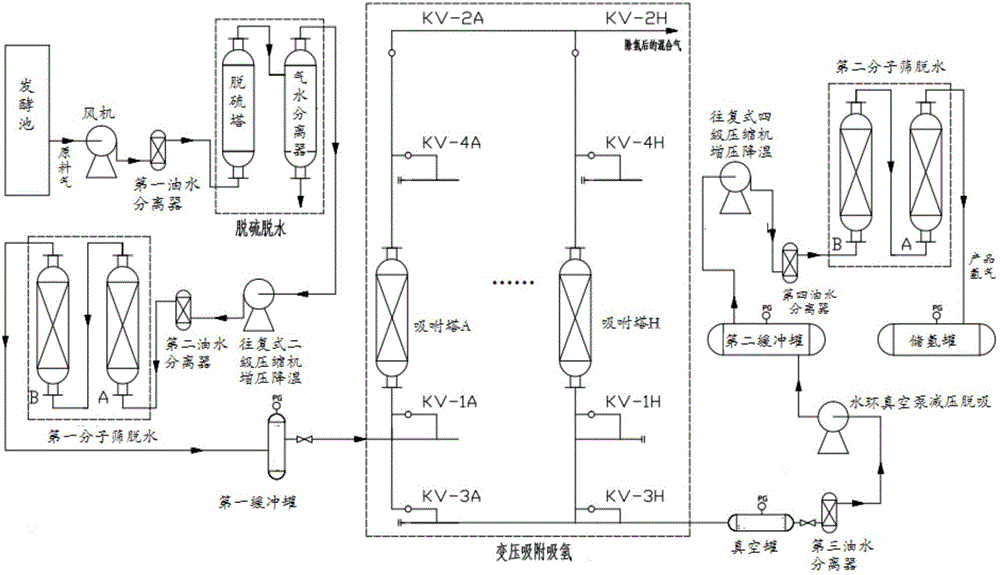

[0027] Such as figure 1 As shown, the hydrogen volume content in the raw material gas coming out of the fermentation tank is 60% to 70%, and the content of other impurity gases such as carbon dioxide and methane is 30% to 40%. The above raw material gas is pumped into the first oil-water separator by the fan Preliminary dehydration and particulate matter, and then enter the desulfurization tower for desulfurization and enter the baffle type gas-water separator to remove free water; the desulfurization agent of the desulfurization tower adopts Fe 2 o 3 、Na 2 SiO 3 and charcoal mixture, Fe 2 o 3 :Na 2 SiO 3 : The mixing mass ratio of charcoal is 2:2:1.

[0028] The desulfurized and dehydrated raw material gas from the baffle type gas-water separator has a temperature of 50°C and a pressure of 0.11-0.13 MPa, and enters the reciprocating secondary compressor for boosting and cooling, and the pressure is increased to 3.8-4.0 MPa, and the temperature is 5 ~15°C. The power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com