Press-filter unidirectional continuous plate pulling device

A one-way continuous, filter press technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of general efficiency, low work efficiency, unreliable performance, etc., and achieve simple structure and movement, saving pull board time, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

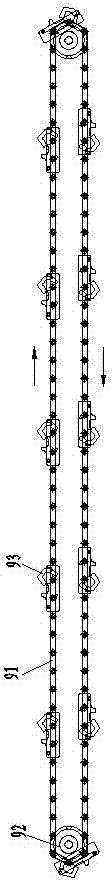

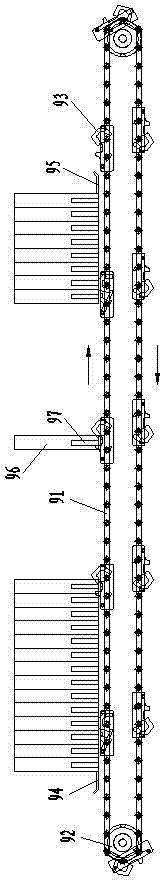

[0027] see Figure 1 to Figure 9 , the one-way continuous plate pulling device of the filter press in this embodiment includes a chain 91, two sprockets 92 and several manipulators 93, wherein the chain 91 is installed on the two sprockets 92, and the sprockets 92 can drive the chain 91 rotates, and several manipulators 93 in the present embodiment are evenly fixed on the chain 91, and the quantity of manipulators 93 among the present invention is usually 6-20.

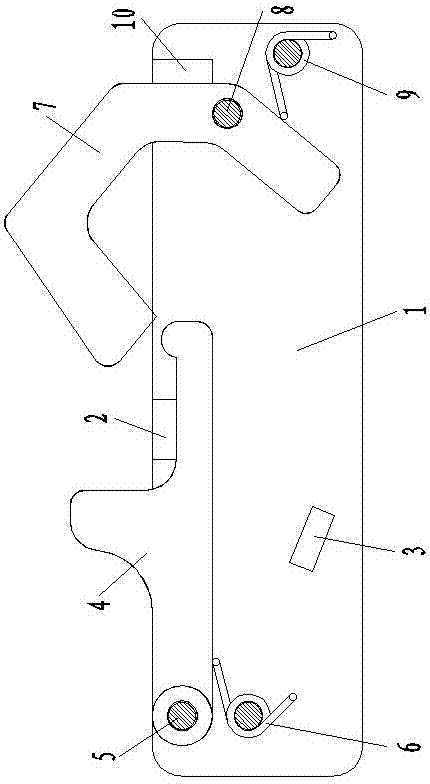

[0028]The manipulator 93 in this embodiment includes a frame body 1, an upper limit block 2, a lower limit block 3, an actuator 4, an execution pin shaft 5, an execution torsion spring 6, a control element 7, a control pin shaft 8, a cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com