Method for preparing carbon aerogel by utilizing normal-pressure drying

A technology of carbon aerogel and atmospheric pressure drying, which is applied in the direction of airgel preparation, carbon preparation/purification, chemical instruments and methods, etc., can solve the problem of affecting carbon aerogel ion transmission capacity and cycle stability, affecting Electrochemical properties of airgel, reducing the specific surface area of RF gel, etc., to achieve the effects of avoiding skeleton collapse, reducing shrinkage, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing carbon airgel by drying under normal pressure:

[0033] (1) Precursor preparation: Weigh 15g of resorcinol, 8.181g of formaldehyde, and 50ml of deionized water, place them in a 500ml beaker, stir on a magnetic stirrer, and wait until the resorcinol is completely dissolved. Add 0.1443g of anhydrous sodium carbonate, stir in a 40-60°C constant temperature oil bath for 30-50min, then add 1.59g of F127 into the above solution and stir until the solution is uniform, then stir in a 60°C constant temperature oil bath for 30-50min , and then add deionized water to make the solid content of the precursor become 40%, and then magnetically stir at a speed of 600-800r / min to obtain a uniformly dispersed reddish-brown emulsion;

[0034] (2) Sol-gel: transfer the reddish-brown emulsion to a stoppered Erlenmeyer flask for sealing; then place the sealed Erlenmeyer flask with a stopper in a constant temperature oil bath at 40-60°C for sol-gel reaction for 1d, The...

Embodiment 2

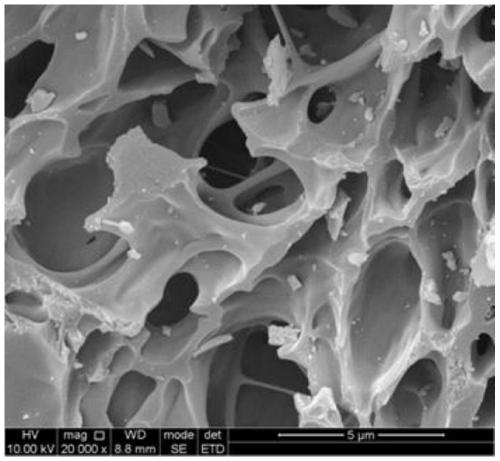

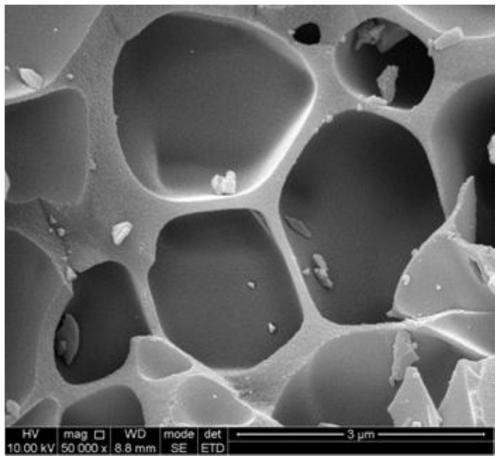

[0039] The amount of F127 in Example 1 was adjusted to 2.01g, other experimental conditions were the same as above, the structure and performance test results of the prepared material were: the specific surface area of the prepared material was 801.1m 2 / g; Electrochemical performance tests show that its specific capacity is 195.77F / g; it provides an energy density of 20.76Wh / kg at a power density of 590.97W / kg, showing good performance; carbon airgel materials in After 2000 cycles at a current density of 0.1A / g, the capacity retention rate reaches 94.38%, and the material performance is better than that of Example 1; the morphology of the prepared material is as follows figure 2 As shown, the specific surface area and pore structure analysis data are shown in Table 1.

[0040] The specific surface area and pore structure analysis data of table 1 embodiment 1 and embodiment 2

[0041] sample S BET (m 2 / g)

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com