Interface oxygen vacancy based stable-storage resistive random access memory achieving method

A technology of resistive storage and oxygen vacancies, which is applied in the direction of electrical components, etc., can solve the problems that Flash storage technology cannot meet the requirements of ultra-high storage density, the programming voltage cannot be reduced proportionally, and the performance of device charge retention is reduced. Resistive storage performance, simple structure, stable and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

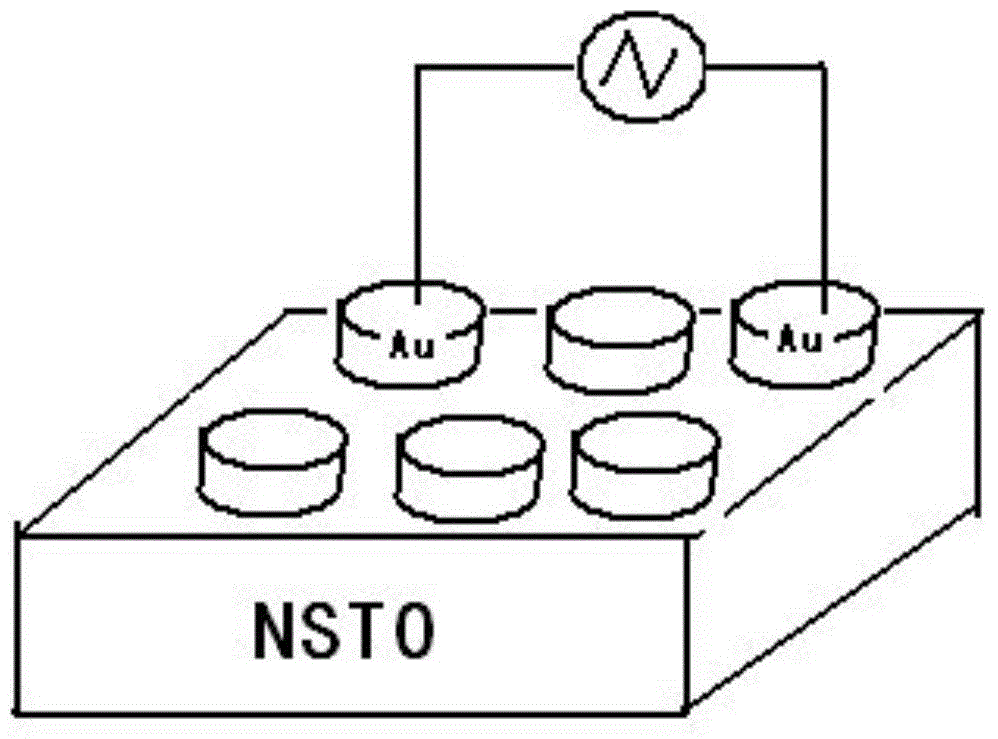

[0023] Take a piece of single crystal SrTiO containing Nb with a size of 10mm×5mm×0.5mm 3 substrate, where the single crystal SrTiO 3 The substrate contains 0.7% Nb, which were ultrasonically cleaned in deionized water, acetone, deionized water, ethanol, and deionized water for 5 min, 15 min, 5 min, 15 min, and 5 min, respectively, and dried naturally. Cover the cleaned substrate with a mask plate, place it in the vacuum chamber of a magnetron sputtering apparatus, and use radio frequency magnetron sputtering method on the exposed Nb-containing single crystal SrTiO 3 A metal gold (Au) film with a thickness of 100nm and a diameter of 1mm is sputtered on the substrate. The schematic diagram of the device structure is shown in figure 1 . The vacuum degree during the RF magnetron sputtering method used is 9.7×10 -4 pa, the sputtering air pressure is 0.8Pa, the sputtering time is 9min, the sputtering power is 60W, and the target base distance is 5cm. Two metal gold (Au) electro...

Embodiment 2

[0025] Same as embodiment 1, get a piece of Nb-containing single crystal SrTiO with a size of 10mm × 5mm × 0.5mm 3 A substrate in which the single crystal SrTiO 3 The substrate contains Nb with a mass content of 0.5%, and it is ultrasonically cleaned in deionized water, acetone, deionized water, ethanol, and deionized water for 5 min, 15 min, 5 min, 15 min, and 5 min, respectively, and dried naturally. Cover the cleaned substrate with a mask plate, place it in the vacuum chamber of a magnetron sputtering apparatus, and use radio frequency magnetron sputtering method on the exposed Nb-containing single crystal SrTiO 3 A metal gold (Au) film with a thickness of 100nm and a diameter of 1mm is sputtered on the substrate. The schematic diagram of the device structure is shown in figure 1 . The vacuum degree during the RF magnetron sputtering method used is 9.7×10 -4 pa, the sputtering air pressure is 0.8Pa, the sputtering time is 9min, the sputtering power is 60W, and the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com