One-step synthetic method of degradable branched polyester

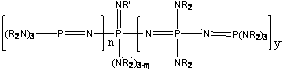

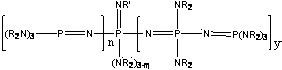

A synthesis method and one-step technology, which are applied in the field of one-step synthesis of degradable branched polyesters, can solve problems such as inability to realize industrialization, cumbersome preparation process, and limited methods, and achieve wide application range, simple polymerization process, and branched polyester. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 1.1g (10mmol) of caprolactone and 24.2μL (0.2mmol) of hydroxyethyl methacrylate, put them in a 25mL sealed tube with a rotor, then add 0.4g of toluene as a solvent, freeze in liquid nitrogen, and replace argon three times. Immediately inject 20 μL (0.02 mmol) of t-BuP under argon atmosphere 4 of n-hexane solution, sealed the tube, placed in an oil bath at 60 °C, and reacted for 2 h. After the reaction, dissolve the reaction product with tetrahydrofuran and add 5 mL of 10 wt% hydrochloric acid solution and 10 mL of ethanol to terminate the reaction and wash the branched polycaprolactone, and then use 100 mL of n-hexane to fully wash the polymer under rapid stirring to remove unreacted. Monomer, (protonated) t-BuP 4 and toluene, filtered, vacuum dried at 50 °C for 12 h, molecular weight was 1.23′10 5 g / mol.

Embodiment 2

[0028] Take 6.6g of caprolactone (60mmol) and 24.2μL (0.2mmol) of hydroxyethyl methacrylate, put them in a 25mL sealed tube with a rotor, then add 3.3g of toluene as a solvent, freeze in liquid nitrogen, and replace argon three times. Immediately inject 1 mL (1 mol) of t-BuP under argon atmosphere 4 of n-hexane solution, sealed the tube, placed in an oil bath at 60 °C, and reacted for 2 h. After the reaction, dissolve the reaction product with tetrahydrofuran and add 5 mL of 10 wt% hydrochloric acid solution and 20 mL of ethanol to terminate the reaction and wash the branched polycaprolactone, and then use 200 mL of n-hexane to fully wash the polymer under rapid stirring to remove unreacted. Monomer, (protonated) t-BuP 4 and toluene, filtered, vacuum dried at 50 °C for 0.5 h, molecular weight was 2.41′10 5 g / mol.

Embodiment 3

[0030] Take 1.1 g (10 mmol) of caprolactone and 24.2 μL (0.2 mmol) of hydroxyethyl methacrylate, put them in a 25 mL sealed tube with a rotor, then add 0.6 g of toluene as a solvent, freeze with liquid nitrogen, and replace argon three times. Immediately inject 60 μL of t-BuP under argon atmosphere 4 The n-hexane solution was sealed, and the tube was placed in an acetone / liquid nitrogen system at -100 °C to react for 2 h. After the reaction, dissolve the reaction product with tetrahydrofuran and add 5 mL of 10 wt% hydrochloric acid solution and 10 mL of ethanol to terminate the reaction and wash the branched polycaprolactone, and then use 100 mL of n-hexane to fully wash the polymer under rapid stirring to remove unreacted. Monomer, (protonated) t-BuP 4 and toluene, filtered, vacuum dried at 50 °C for 48 h, molecular weight was 1.51′10 5 g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com