Preparation method of lithium ion battery carbon cathode material coating layer

A carbon anode material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult to achieve consistency in polymerization, difficult to achieve mass production, poor safety, etc., to reduce coating costs, The effect of low cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

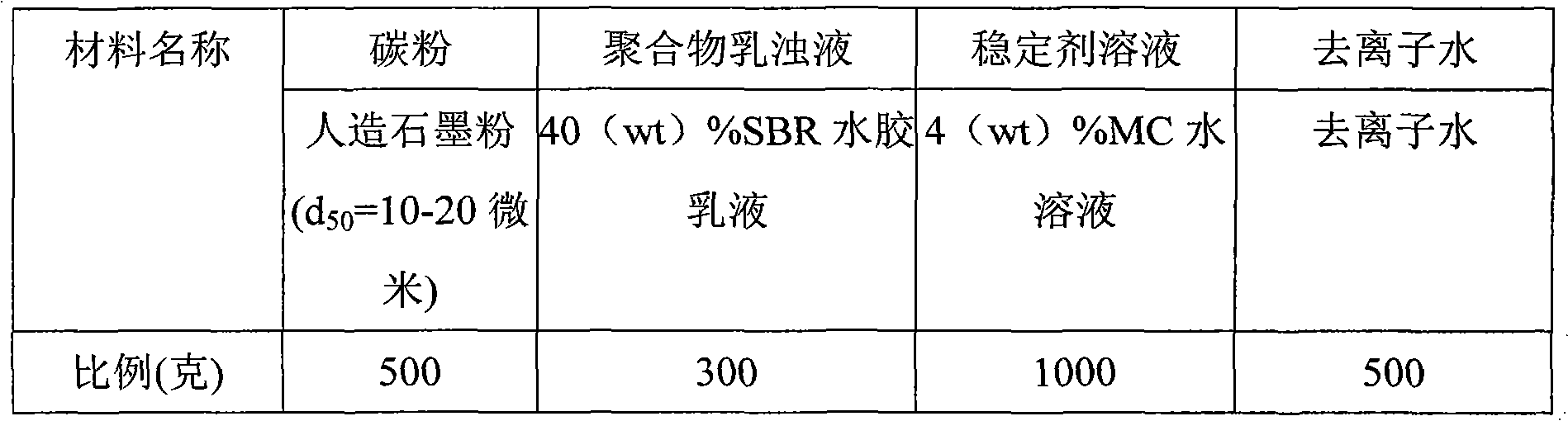

[0020] Preparation of slurry:

[0021]

[0022] First 500 grams of 4 (wt)% MC aqueous solution, and 500 grams of artificial graphite powder (d 50 = 10-20 microns) mixed, placed in the planetary mill, started the mixer, mixed and stirred for 1 hour; added 500 grams of 4 (wt)% MC aqueous solution, and stirred for 2 hours; added styrene-butadiene rubber (SBR) emulsion 300 grams (the water-gel emulsion contains 40% SBR, and the particle size is 100-150 nanometers), stirred for 1 hour; added 500 grams of deionized water and stirred for another half an hour.

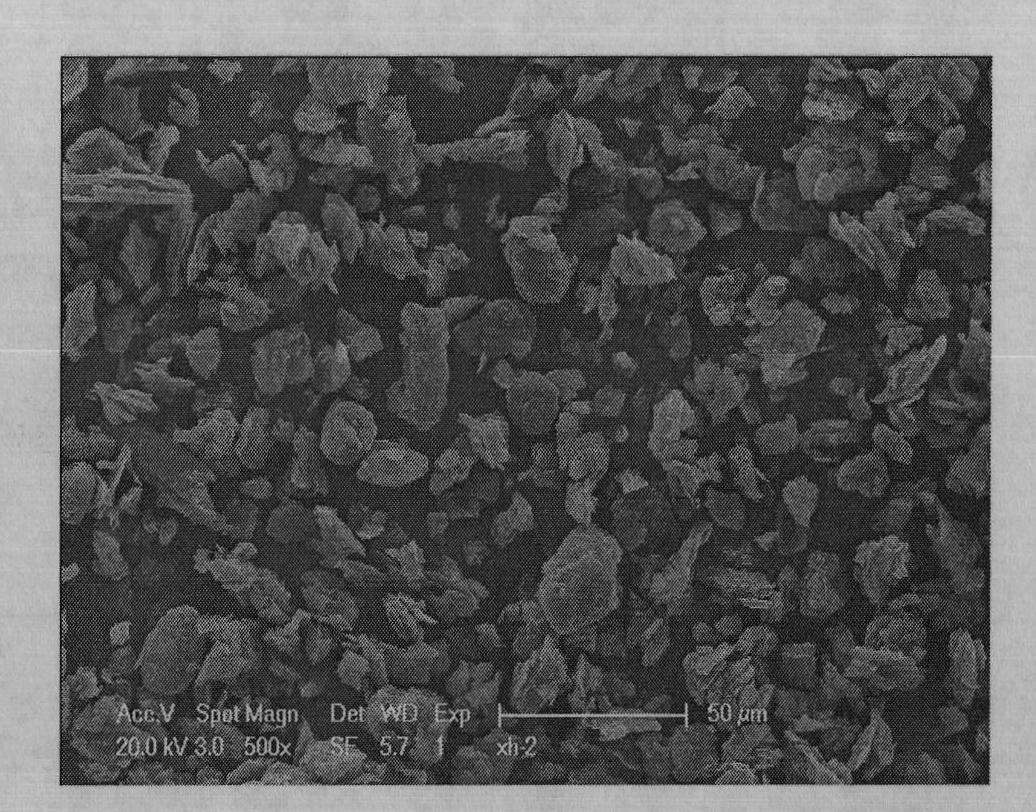

[0023] The above-mentioned slurry is transported into a spray drying granulator for granulation and coating. The slurry emulsion is dispersed into mist droplets through an atomizer. The mist droplets are in contact with hot dry air to remove moisture and become powdery particles. The surface of graphite powder is coated with styrene-butadiene rubber (SBR) and methyl cellulose (MC). This step is a traditional technical met...

Embodiment 2

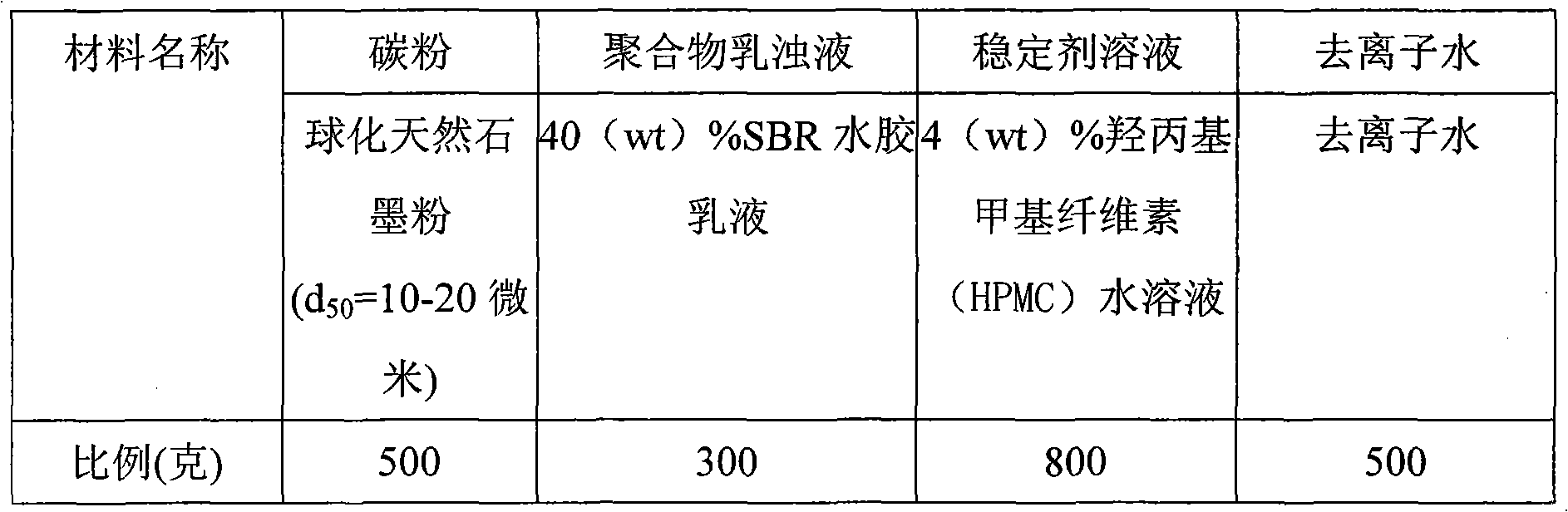

[0026] Preparation of slurry:

[0027]

[0028] First 400 grams of 4% hydroxypropyl methylcellulose (HPMC) aqueous solution, and 500 grams of spheroidized natural graphite powder (d 50 =10-20 micron) mix, place in planetary mill, start mixer, mix and stir 1 hour; Add 400 grams of 4 (wt)% hydroxypropyl methylcellulose (HPMC) aqueous solution, stir again 2 hours; Add butylbenzene 300 grams of rubber (SBR) emulsion (water-based emulsion containing SBR 40 (wt)%, particle size is 100-150 nanometers), stirred for 1 hour; added 500 grams of deionized water and stirred for another half an hour. The above-mentioned slurry is transported into a spray drying granulator for granulation and coating. The slurry emulsion is dispersed into mist droplets through an atomizer. The mist droplets are in contact with hot dry air to remove moisture and become powdery particles. The surface of spheroidized natural graphite powder is coated with styrene-butadiene rubber (SBR) and hydroxypropyl met...

Embodiment 3

[0031] Preparation of slurry:

[0032]

[0033] First 500 grams of 4% hydroxyethylmethylcellulose (HEMC) aqueous solution, and 500 grams of artificial graphite powder (d 50= 10-20 microns) mixed, placed in the planetary mill, started the mixer, mixed and stirred for 1 hour; added 500 grams of 4 (wt)% hydroxyethyl methylcellulose (HEMC) aqueous solution, and stirred for 2 hours; added SBR to modify 400 grams of emulsified petroleum asphalt water-gel emulsion (SBR5(wt)%+asphalt 20(wt)%+75(wt)% water) was stirred for 1 hour; 750 grams of deionized water was added and stirred for another half an hour. The above-mentioned slurry is transported into a spray drying granulator for granulation and coating. The slurry emulsion is dispersed into mist droplets through an atomizer. The mist droplets are in contact with hot dry air to remove moisture and become powdery particles. The surface of graphite powder is coated with styrene-butadiene rubber (SBR), asphalt and hydroxyethyl methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com