Molten metal coated ternary precursor and preparation method thereof

A technology of molten metals and precursors, applied in the field of electrochemistry, can solve problems such as uneven coating, affecting production and yield, and difficult precipitation, so as to improve coating uniformity, excellent temperature stability, and simplify cumbersome steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

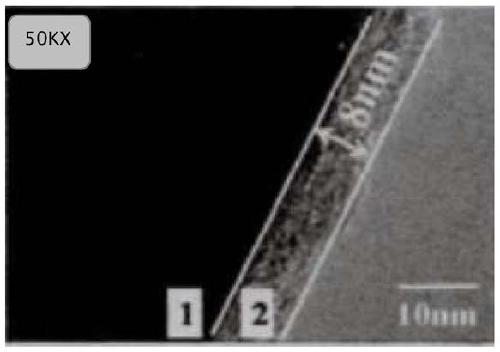

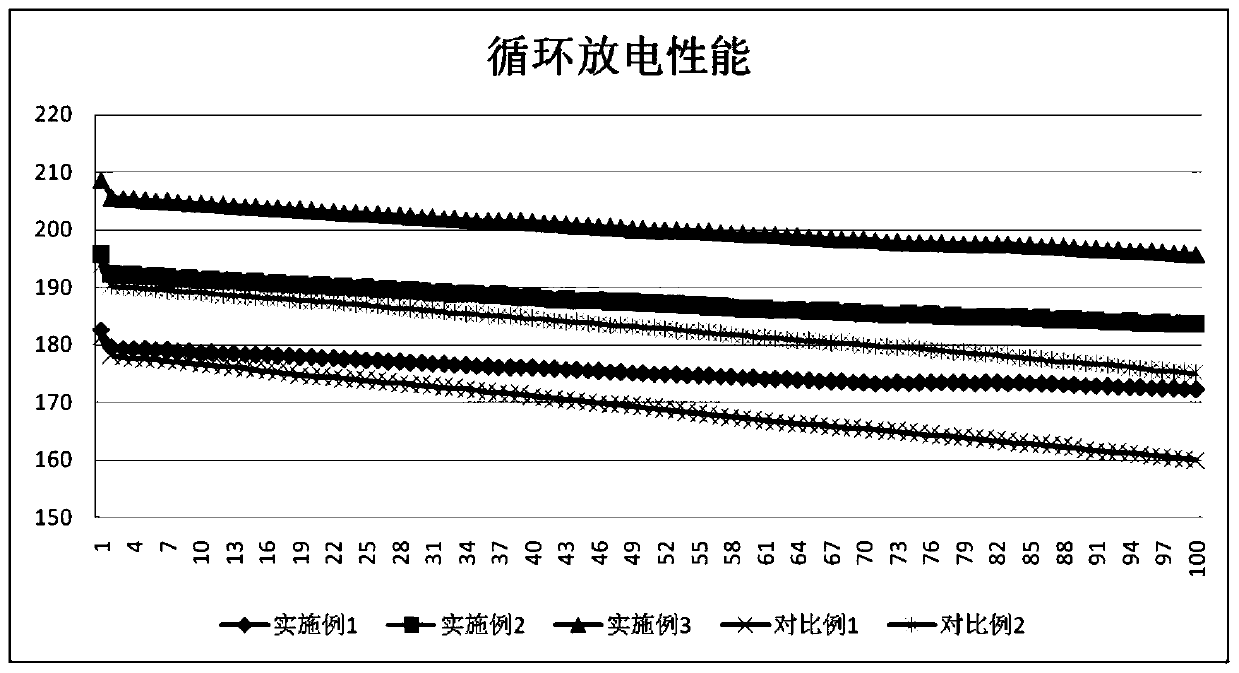

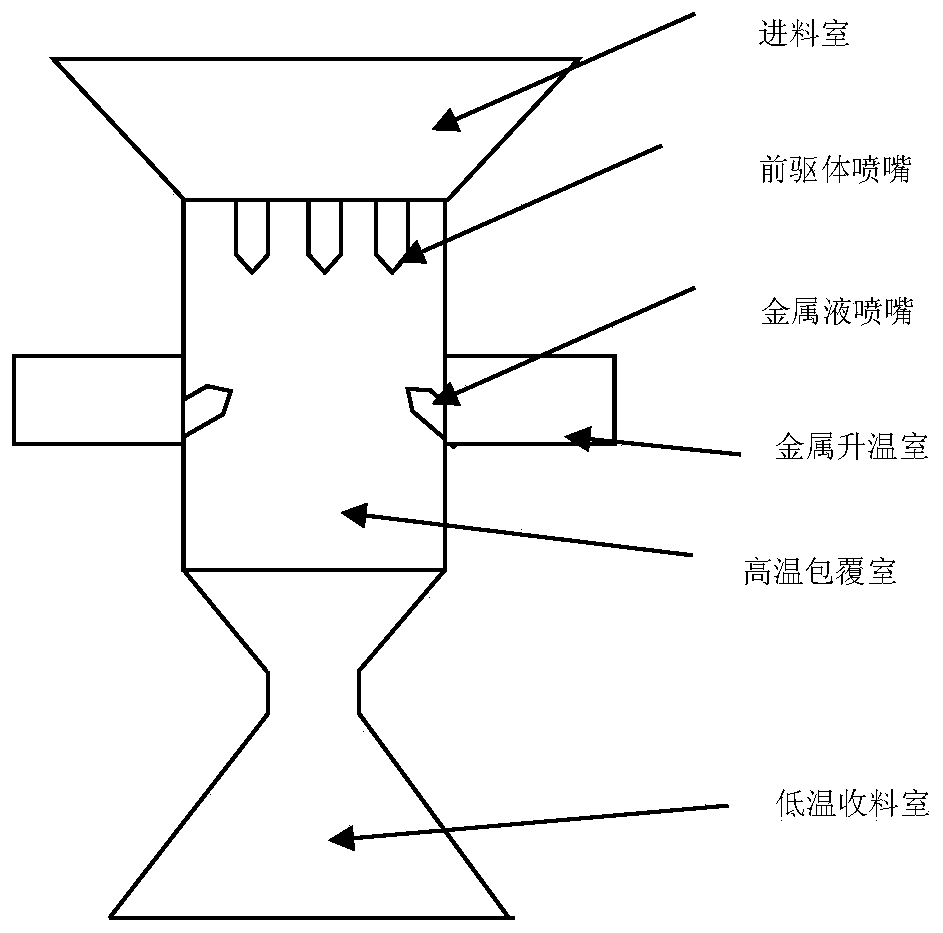

Embodiment 1

[0040] Weigh 6mol of nickel nitrate, 2mol of cobalt nitrate, and 2mol of manganese nitrate, dissolve them in 2.5L deionized water, and make a 4mol / L A solution; take 18mol of sodium hydroxide and dissolve them in 9L of deionized water, and add 3mol of ammonium nitrate, fully Dissolve to make a B solution with a precipitant concentration of 2mol / L; take 0.005mol of metal tin and place it in a melting device under the protection of argon to heat up to 255°C (the melting point of metal tin is 231.93°C) to obtain tin metal liquid C; It is added into the reaction tank concurrently with the B solution, and the chemical composition is Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor, wash the precursor with deionized water to remove impurities, and then dry it. In the precursor feeding room, control the temperature of the coating room at about 255°C, the temperature of the receiving room at about 180°C, and open the precursor nozzle at the same time And the metal liquid nozzle, so that the p...

Embodiment 2

[0043] Weigh 6.5mol of nickel chloride, 1.5mol of cobalt chloride, and 2mol of manganese chloride, dissolve them in 10L deionized water, and make a 1mol / L A solution; dissolve 18mol of sodium hydroxide in 2.25L deionized water, and add 1.5 mol of ammonium chloride was fully dissolved to make solution B with a precipitant concentration of 8 mol / L; 0.025 mol of metal bismuth was taken and placed in a melting device under the protection of argon and the temperature was raised to 320°C (the melting point of metal bismuth was 271.3°C) to obtain bismuth Metal liquid C; A solution and B solution are added into the reaction tank in parallel to obtain a chemical composition of Ni 0.65 co 0.15 mn 0.2 (OH) 2 For the precursor, wash the precursor with deionized water to remove impurities, and then dry it. In the precursor feeding room, control the temperature of the coating room at about 320°C and the temperature of the receiving room at about 210°C, and open the precursor nozzle at the...

Embodiment 3

[0046] Take 8.5 mol of nickel chloride, 0.5 mol of cobalt chloride, and 1 mol of manganese chloride and dissolve them in 5L deionized water to make a 2mol / L A solution; take 18 mol of sodium hydroxide and dissolve them in 4.5L deionized water, and add 0.5 mol ammonium nitrate, fully dissolved to make B solution with a precipitant concentration of 4mol / L; take 0.05mol of metallic lead and place it in a melting device under the protection of argon to heat up to 370°C (the melting point of metallic lead is 327.46°C) to obtain lead metal liquid C; A solution and B solution are added into the reaction tank in parallel to obtain a chemical composition of Ni 0.85 co 0.05 mn 0.1 (OH) 2 For the precursor, wash the precursor with deionized water to remove impurities, and then dry it. In the precursor feeding room, control the temperature of the coating room at about 370°C and the temperature of the receiving room at about 220°C, and open the precursor nozzle at the same time and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com