Cable wrapping machine wrapping drum

A wrapping machine and wrapping technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of poor quality and stability of cable wrapping, achieve the effect of no need for rework, reduce wrapping costs, and eliminate lap slack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

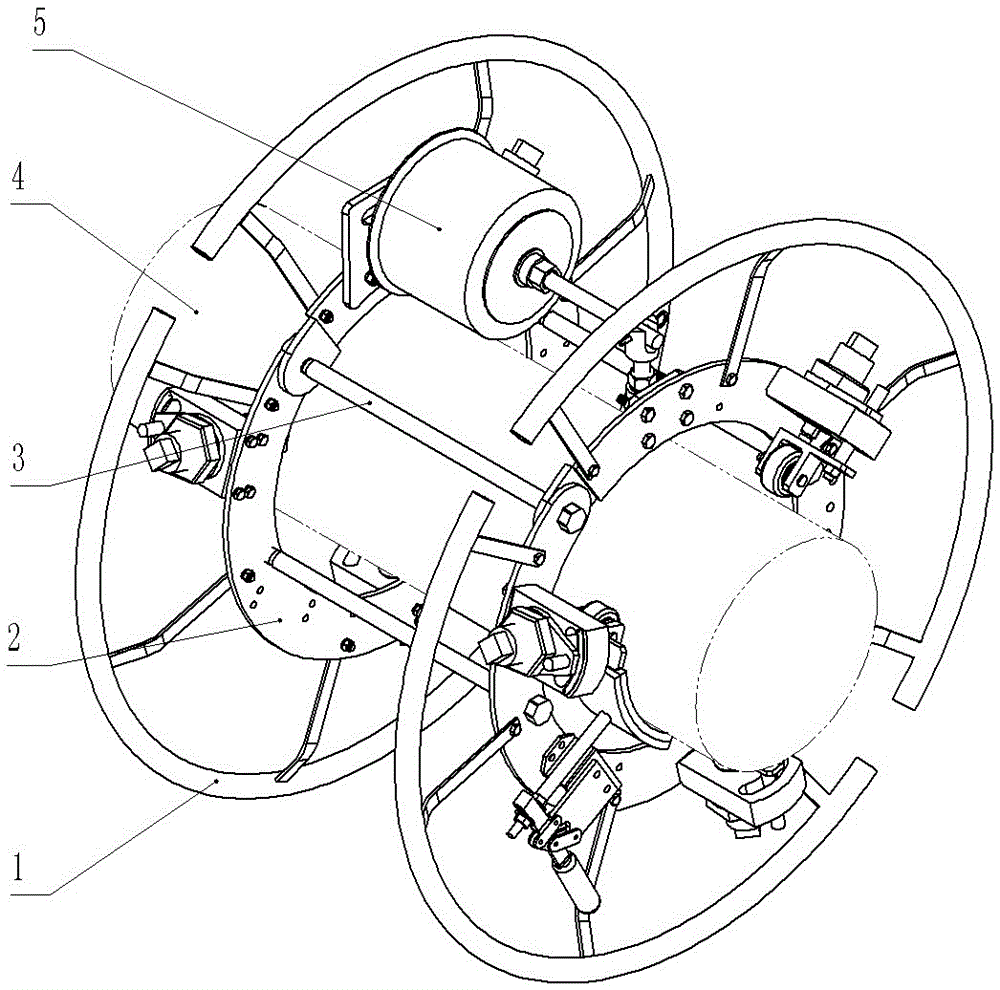

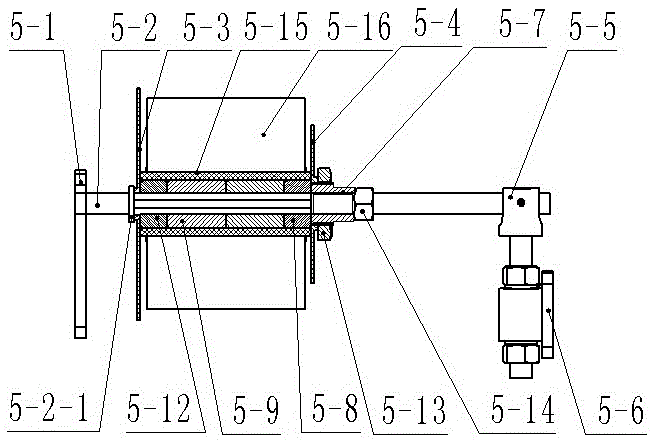

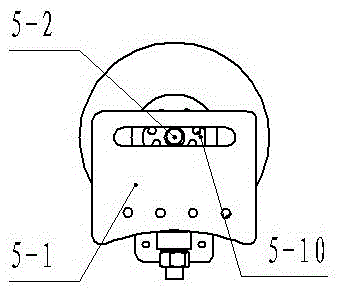

[0014] Such as figure 1 The shown cable wrapping machine wrapping cylinder includes two circular liners with a central hole formed by a plurality of lapped end-to-end arc-shaped side plates 2. Consisting of arc-shaped side plates 2, each arc-shaped side plate 2 is connected with an arc-shaped handle ring 1 by bolts; multiple axial connecting rods are installed between the two annular liners 3. The two annular liners are fixedly connected by nuts screwed on a plurality of axial connecting rods 3 . A roller 5-2 with a positioning platform 5-2-1 is arranged between the arc-shaped side plates 2 of the two annular liners, on one side of the roller 5-2 positioning platform 5-2-1 The outer baffle 5-3, the front limit ring 5-12, the rear limit ring 5-8, the tension nut 5-7 and the positioning nut 5-14 crimped with the tension nut 5-7 are sequentially installed , the tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com