Preparation method of amino polyether organic silicon compounded antifoaming agent

A technology of amino polyether and silicone, which is applied in the direction of foam dispersion/prevention, can solve the problem of single component, etc., and achieve the effect of excellent anti-foaming performance, excellent heat resistance, acid and alkali resistance, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

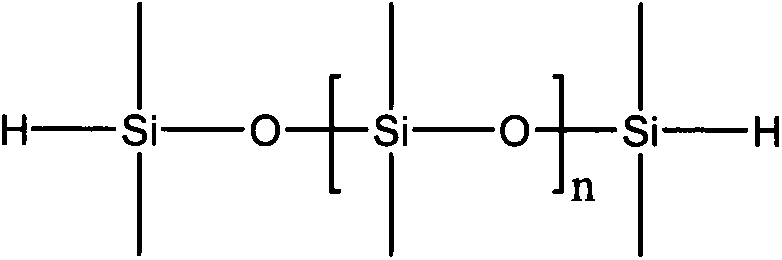

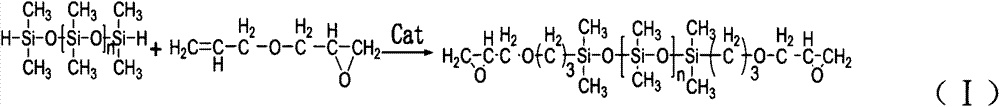

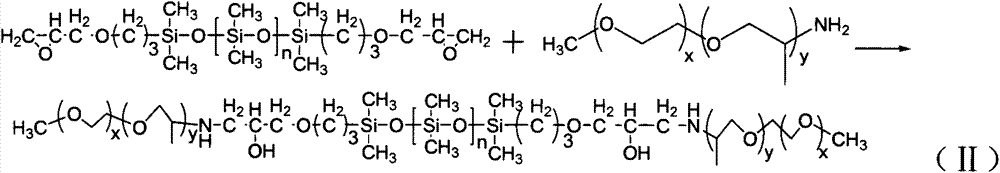

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A kind of method for preparing aminopolyether silicone composite type defoamer, comprises the following steps:

[0042] Preparation of epoxy modified silicone oil:

[0043] Weigh 20g terminal hydrogen-containing silicone oil (the active hydrogen mass fraction is 0.2478%), dissolve it in 25ml toluene, weigh 6.788g allyl glycidyl ether (0.05947mol) and platinum catalyst 0.1049g (accounting for about 1% of the total mass of reactants) 30ppm), allyl glycidyl ether and platinum catalyst are added to the container, under N 2 Stir and heat under the conditions of protection and reflux condensation. After the temperature rises to 60°C, start to drop the toluene solution containing hydrogen silicone oil through the constant pressure dropping funnel at a rate of 1 drop / second, and continue to heat up to 90°C. The toluene was removed on a rotary evaporator, and finally vacuum-dried at 80° C. for 12 hours with a vacuum degree of 0.09 MPa to obtain epoxy-terminated si...

Embodiment 2

[0050] Embodiment 2: A kind of method for preparing amino polyether silicone composite type defoamer, comprises the following steps:

[0051] Preparation of amino polyether silicone compound defoamer:

[0052] Weigh 3g of amino polyether silicone (E-M-2005) and 2g of silicone paste into a 100mL three-neck flask, and add emulsifiers Span-60 (Span-60) and Tween-60 (Tween-60) each 0.75g, 0.5 g, heat and stir in a water bath to raise the temperature to 60-70°C, keep it warm for 1 hour, weigh 0.102g polyethylene glycol 6000 distearate (638) into a 100mL beaker, add 18.7g deionized water, place Stir on a magnetic stirrer. After the thickener is completely dissolved and dispersed in the water phase, pour it into a constant pressure dropping funnel, and then slowly add it dropwise to the oil phase. After the thickener aqueous solution is added dropwise, keep warm Stir for 30 minutes, cool to room temperature, and stir for 15 minutes with a shear emulsification mixer to obtain a white...

Embodiment 3

[0056] Embodiment three: a kind of method for preparing aminopolyether silicone composite type defoamer, comprises the following steps:

[0057] Preparation of amino polyether silicone compound defoamer:

[0058] Weigh 3g of amino polyether silicone (E-M-2005) and 2g of silicone paste into a 100mL three-necked flask, and add emulsifiers Span-60 (Span-60) and Tween-60 (Tween-60) each 0.375g0.25g , heated in a water bath and stirred to raise the temperature to 60-70°C, and keep it warm for 1 hour. At the same time, weigh 0.128g of polyethylene glycol 6000 distearate (638) into a 100mL beaker, add 19.2g of deionized water, and place it under a magnetic force Stir on the agitator. After the thickener is completely dissolved and dispersed in the water phase, pour it into the constant pressure dropping funnel, and then slowly add it dropwise to the oil phase. After the thickener aqueous solution is added dropwise, keep stirring After 30 minutes, cool to room temperature, and stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com