Preparation method of polyether polyester modified silicone oil

A technology of polyether polyester and modified silicon, which is applied in the field of preparation of polyether polyester modified silicone oil, can solve problems such as inability to infer the connection position of active groups, failure to meet application requirements, and uncertain molecular weight, etc. Easy to yellow, not easy to stick to the roller, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of polyether polyester modified silicone oil, the steps are as follows:

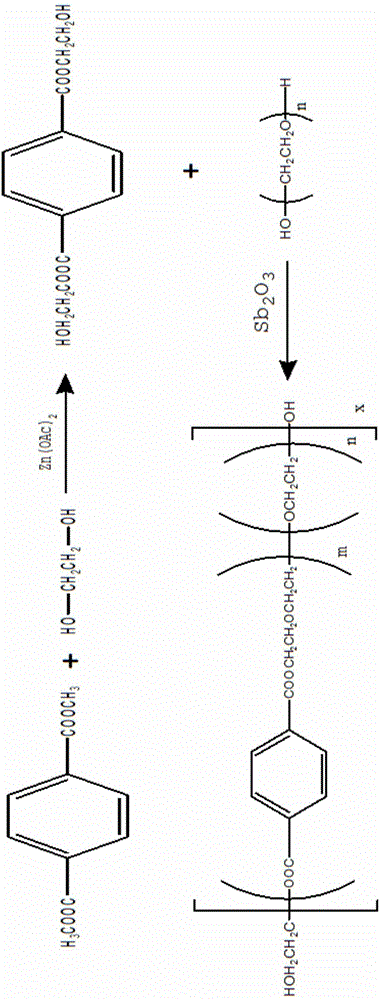

[0026] 1. Synthesis of polyether polyester block copolymer

[0027] Synthetic roadmap as figure 1 As shown, add 48.5g of dimethyl terephthalate and 38.7g of ethylene glycol into the reaction vessel, raise the temperature to 150°C and stir for 10min, add 0.1g of zinc acetate and continue to stir for 10min, then raise the temperature to 190°C to start the transesterification reaction to obtain Ethylene terephthalate, the reaction time is 30min. Next, add 125g of ethylene terephthalate, 0.1g of antimony oxide and 0.5g of polyethylene oxide into the reaction vessel, stir, vacuumize, and raise the temperature to 230°C to start the polycondensation reaction to obtain a polyether polyester block copolymer , control the polycondensation reaction temperature does not exceed 260 ~ 270 ℃, the reaction time is 60min.

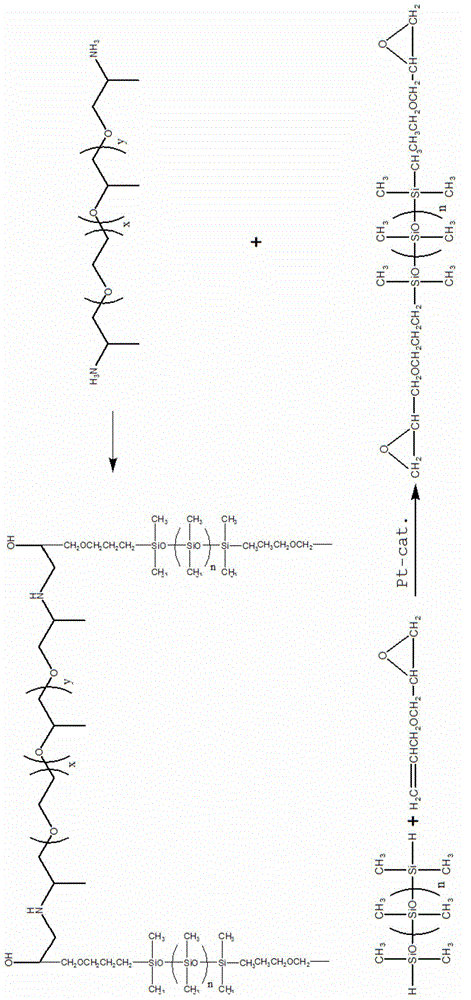

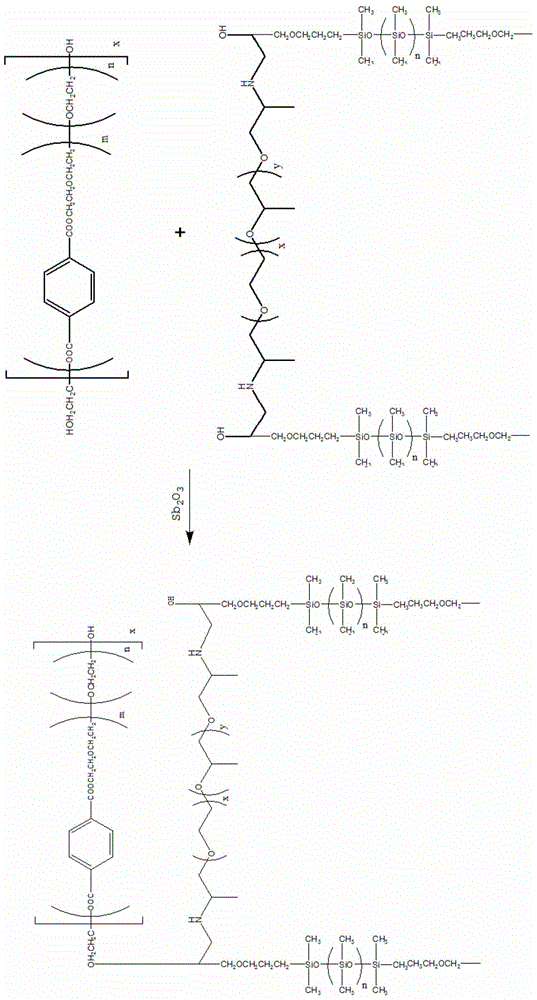

[0028] 2. Synthesis of polyether amino modified silicone oil

[...

Embodiment 2

[0033] The preparation method of polyether polyester modified silicone oil, the steps are as follows:

[0034] 1. Synthesis of polyether polyester block copolymer

[0035] Synthetic roadmap as figure 1 As shown, add 48.5g of dimethyl terephthalate and 38.7g of ethylene glycol into the reaction vessel, raise the temperature to 150°C and stir for 10min, add 0.1g of zinc acetate and continue to stir for 10min, then raise the temperature to 190°C to start the transesterification reaction to obtain Ethylene terephthalate, the reaction time is 20min. Next, add 125g of ethylene terephthalate, 0.1g of antimony oxide and 0.5g of polyethylene oxide into the reaction vessel, stir, vacuumize, and raise the temperature to 230°C to start the polycondensation reaction to obtain a polyether polyester block copolymer , control the polycondensation reaction temperature does not exceed 260 ~ 270 ℃, the reaction time is 30min.

[0036] 2. Synthesis of polyether amino modified silicone oil

[...

Embodiment 3

[0041] The preparation method of polyether polyester modified silicone oil, the steps are as follows:

[0042] 1. Synthesis of polyether polyester block copolymer

[0043] Synthetic roadmap as figure 1 As shown, add 48.5g of dimethyl terephthalate and 38.7g of ethylene glycol into the reaction vessel, raise the temperature to 150°C and stir for 10min, add 0.1g of zinc acetate and continue to stir for 10min, then raise the temperature to 190°C to start the transesterification reaction to obtain Ethylene terephthalate, the reaction time is 5h. Next, add 125g of ethylene terephthalate, 0.1g of antimony oxide and 0.5g of polyethylene oxide into the reaction vessel, stir, vacuumize, and raise the temperature to 230°C to start the polycondensation reaction to obtain a polyether polyester block copolymer , control the polycondensation reaction temperature does not exceed 260 ~ 270 ℃, the reaction time is 3h.

[0044] 2. Synthesis of polyether amino modified silicone oil

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com