Preparation method of aminopolyether modified polysiloxane deforming agent

A technology of polysiloxane defoamer and amino polyether, which is applied in the field of defoamers, can solve the problems of poor polarity and poor water solubility, and achieve the effect of mild conditions, strong hydrophilicity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

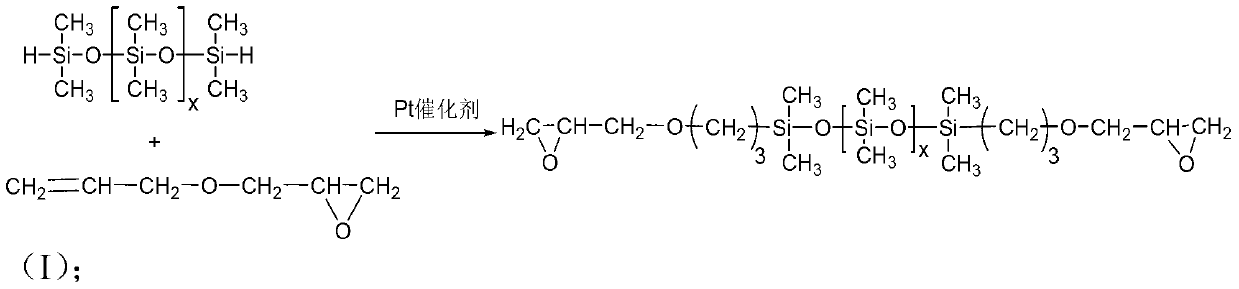

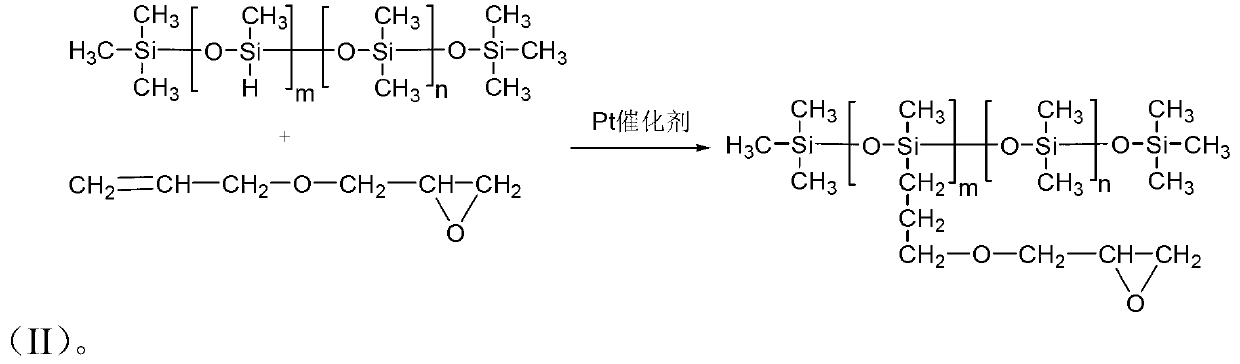

[0015] In the preparation steps of the epoxy-modified silicone oil described in the present invention, in order to promote the reaction to be as thorough as possible, it is necessary to control several key factors such as the feed ratio of the reactants, the order of feed, and the reaction temperature: (1) Reaction Ratio of materials: In order to make the hydrogen-containing silicone oil react as completely as possible, it is necessary to control the amount of allyl glycidyl ether to be slightly excessive compared with the hydrogen-containing silicone oil, so that the hydrogen-containing silicone oil can be fully reacted, thereby increasing the shrinkage of the allyl glycidyl ether. Grafting rate of glycerol ether; (2) Feeding sequence: When preparing epoxy-modified silicone oil, it is necessary to preheat allyl glycidyl ether and chloroplatinic acid catalyst first, and then use the mixed solution of hydrogen-containing silicone oil and toluene to Constant pressure dropping fun...

Embodiment 1

[0035] Embodiment 1: A kind of preparation method of amino polyether modified polysiloxane defoamer, comprises the following process steps:

[0036] (1) Weigh 20g of terminal hydrogen-containing silicone oil (the mass of H atoms in the Si-H bond in the hydrogen-containing silicone oil accounts for 0.2478% of the mass of the hydrogen-containing silicone oil), dissolve the hydrogen-containing silicone oil in 25ml of toluene, and obtain the toluene of the hydrogen-containing silicone oil solution; weigh 6.788g (0.05947mol) allyl glycidyl ether and 0.1049g platinum catalyst, the amount of platinum catalyst added is 30ppm of the total mass of hydrogen-containing silicone oil and allyl glycidyl ether; Add the platinum catalyst into the container and mix it. After heating up to 60°C under the condition of nitrogen protection and reflux condensation, start to drop the toluene solution containing hydrogen silicone oil at a rate of 2 drops / second; continue to heat up to 90°C, under nitro...

Embodiment 2

[0042] Embodiment two: a kind of preparation method of amino polyether modified polysiloxane defoamer, comprises the following process steps:

[0043] (1) Weigh 3 g of epoxy-modified silicone oil (epoxy group is 0.005691 mol) obtained in Example 1 with an epoxy value of 0.1897 mol / 100 g;

[0044] (2) Add epoxy-modified silicone oil and 6.7270g of M-1000 (amine group content: 0.005691mol) into the container, measure 10ml of ethanol into the container as a solvent, stir and mix evenly; under the conditions of nitrogen protection and reflux condensation Carry out reaction, reaction temperature is 95 ℃, and reaction time is 12 hours; After reaction finishes, remove ethanol on rotary evaporator, and the temperature of rotary evaporator is 55 ℃, and pressure is-0.08MPa, and processing time is 22 minutes; Drying at 55° C. and vacuum degree of -0.09 MPa for 12 hours gave a light yellow amino polyether modified polysiloxane defoamer.

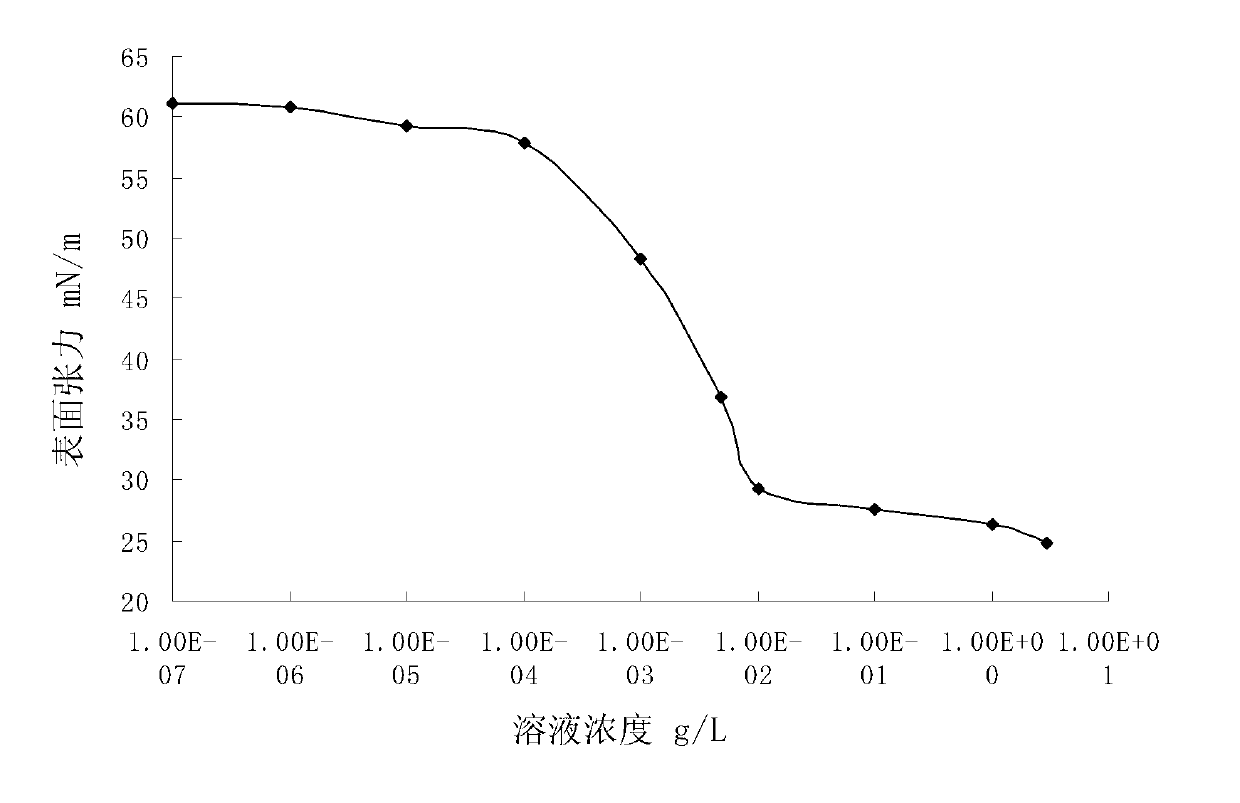

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical micelle concentration | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com