Polysiloxane fire retardant containing nitrogen, phosphorus and silicon, and preparation method thereof

A technology of polysiloxane and flame retardant, which is applied in the field of polysiloxane flame retardant and its preparation, can solve problems such as complex synthesis steps, and achieve the goal of improving crosslinking strength, good flame retardant effect, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

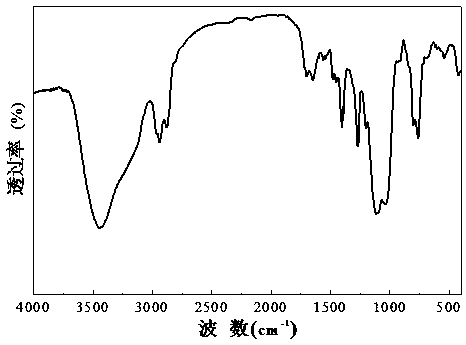

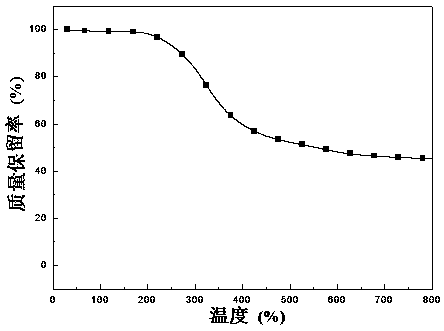

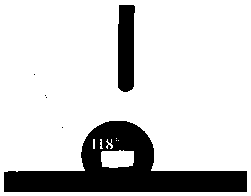

Method used

Image

Examples

Embodiment 1

[0055] Mix 5 parts of poly(methylhydrogensiloxane-dimethylsiloxane copolymer), 6*10 -5 Parts of Karstdet catalyst and 50 parts of isopropanol were added to a four-necked flask equipped with a reflux condenser, a thermometer, magnetic stirring, and an inert atmosphere, and the temperature was raised to 70°C and then stirred at a constant temperature for 15 minutes; after the temperature was raised to 100°C, the 15 parts of isocyanate propyltriethoxysilane and 15 parts of isopropanol in the pressure funnel were added dropwise into the four-necked flask, and the constant temperature reaction was continued for 6 hours; within 2 hours, 35 parts of allyl triethoxysilane in the constant pressure funnel Glycidyl ether and 20 parts of isopropanol were added dropwise in a four-necked flask, and the constant temperature reaction was continued for 6 hours; the solvent and unreacted substances were removed by distillation under reduced pressure to obtain the flame retardant intermediate API...

Embodiment 2

[0061] 10 parts of 1,3,5,7-tetramethylcyclotetrasiloxane, 4*10 -5 Parts of Speier catalyst and 60 parts of toluene solvent were added to a four-necked flask equipped with a reflux condenser, a thermometer, magnetic stirring, and an inert atmosphere, and the temperature was raised to 70°C and then stirred at a constant temperature for 10 minutes; after the temperature was raised to 95°C, the 10 parts of isocyanate propyltriethoxysilane and 15 parts of toluene in the funnel were added dropwise into the four-necked flask, and the reaction was continued at constant temperature for 8 hours; within 2 hours, 30 parts of allyl glycidyl ether in the constant pressure funnel Add 35 parts of toluene dropwise in a four-neck flask, continue the constant temperature reaction for 7h; remove the solvent and unreacted substances by distillation under reduced pressure to obtain the flame retardant intermediate API; all the flame retardant intermediate API obtained in the previous step , 35 part...

Embodiment 3

[0063] Mix 6 parts of polymethylhydrogen siloxane, 7*10 -5Parts of Speier catalyst and 70 parts of toluene solvent were added to a four-necked flask equipped with a reflux condenser, a thermometer, magnetic stirring, and an inert atmosphere, and the temperature was raised to 70°C and then stirred at a constant temperature for 10 minutes; after the temperature was raised to 100°C, the 10 parts of 3-isocyanatopropyl trimethoxysilane and 15 parts of toluene in the funnel were added dropwise into the four-necked flask, and the constant temperature reaction was continued for 7 hours; 50 parts of allyl glycidyl ether in the constant pressure funnel were added within 3 hours Add 20 parts of toluene dropwise in a four-neck flask, continue the constant temperature reaction for 5h; remove the solvent and unreacted substances by distillation under reduced pressure to obtain the flame retardant intermediate API; all the flame retardant intermediate API obtained in the previous step , 30 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com