Patents

Literature

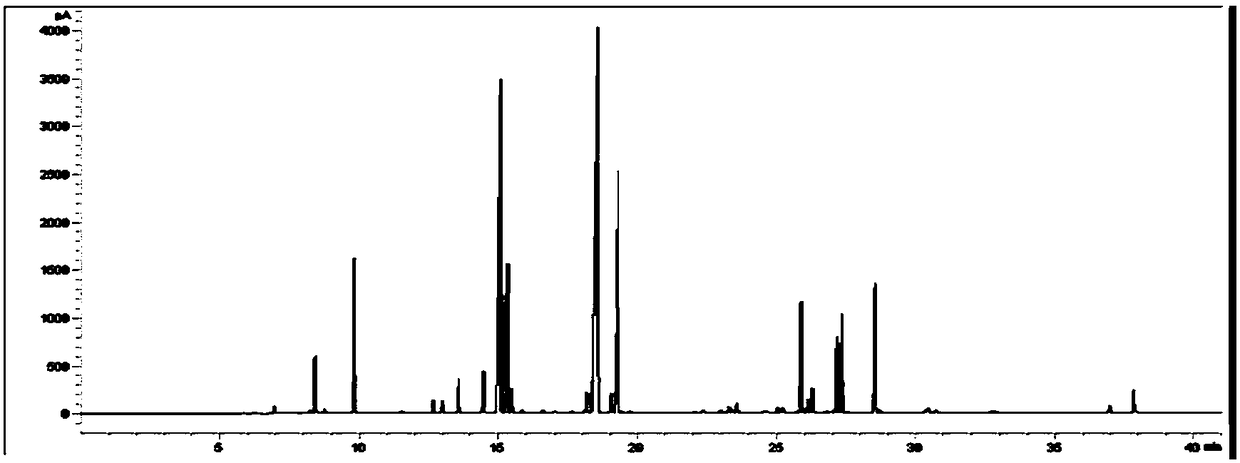

258 results about "CITRIC ACID/SODIUM CITRATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

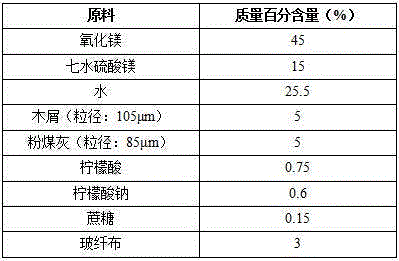

Novel inorganic decoration base material plate and preparation method thereof

InactiveCN105130350AImprove water and moisture resistanceAdjust clotting timeSucroseMoisture absorption

The present invention discloses a novel inorganic decoration base material plate and a preparation method thereof. The novel inorganic decoration base material plate is prepared from the following raw materials by weight: 45-50% of magnesium oxide, 15-20% of magnesium sulfate, 1-1.5% of a modifier, 5-10% of a filler, 1-5% of a reinforcing material, and the balance of water. According to the present invention, the magnesium sulfate is used to replace the magnesium chloride as the gelling material, such that the prepared base material plate almost does not contain chlorine ions; the mixture of citric acid, sodium citrate and sucrose is adopted as the modifier so as to adjust the condensation time and significantly increase the water resistance and the dampness resistance of the base material plate; and the prepared base material plate has characteristics of good waterproof performance, no moisture absorption efflorescence, high strength, cracking deformation resistance, good flexibility, good durability, significantly improved fireproof performance, no formaldehyde release during production and use processes, safety and environmental protection, and can be widely used as the base plates of fireproof plates, suspended ceiling plates, decorative plates, partition boards and other plates.

Owner:惠州美森板业有限公司

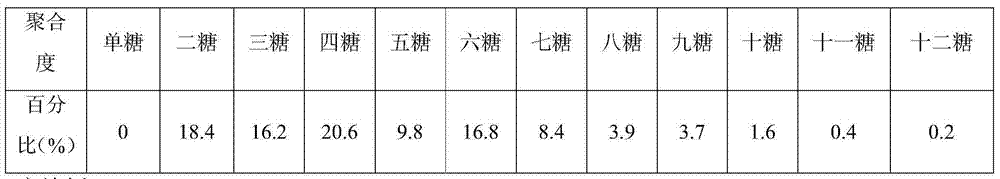

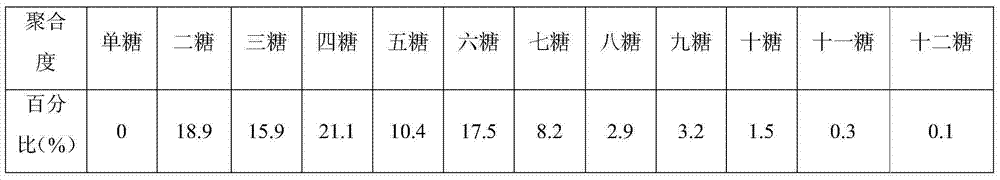

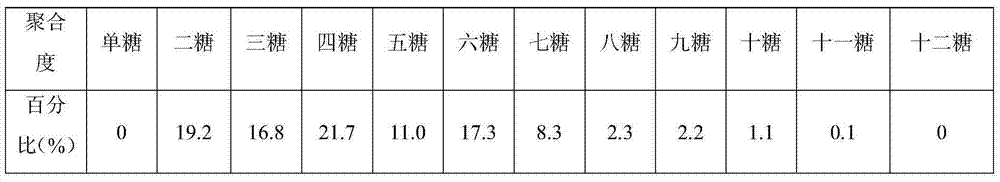

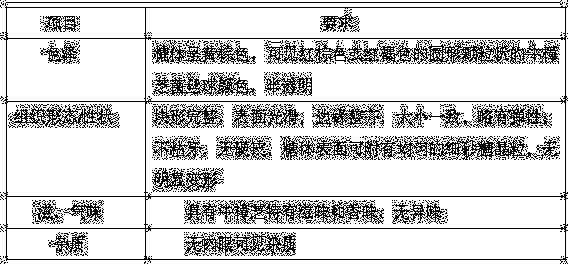

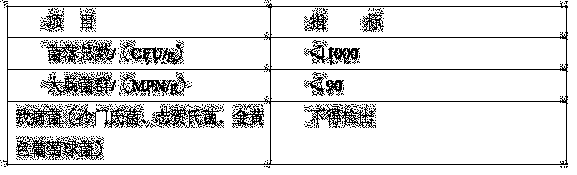

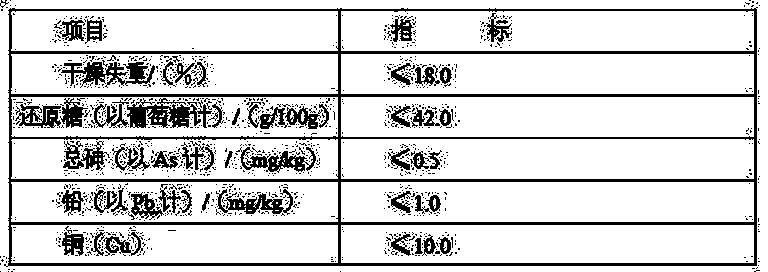

Konjak jelly and processing method thereof

Owner:CHACHA FOOD CO LTD

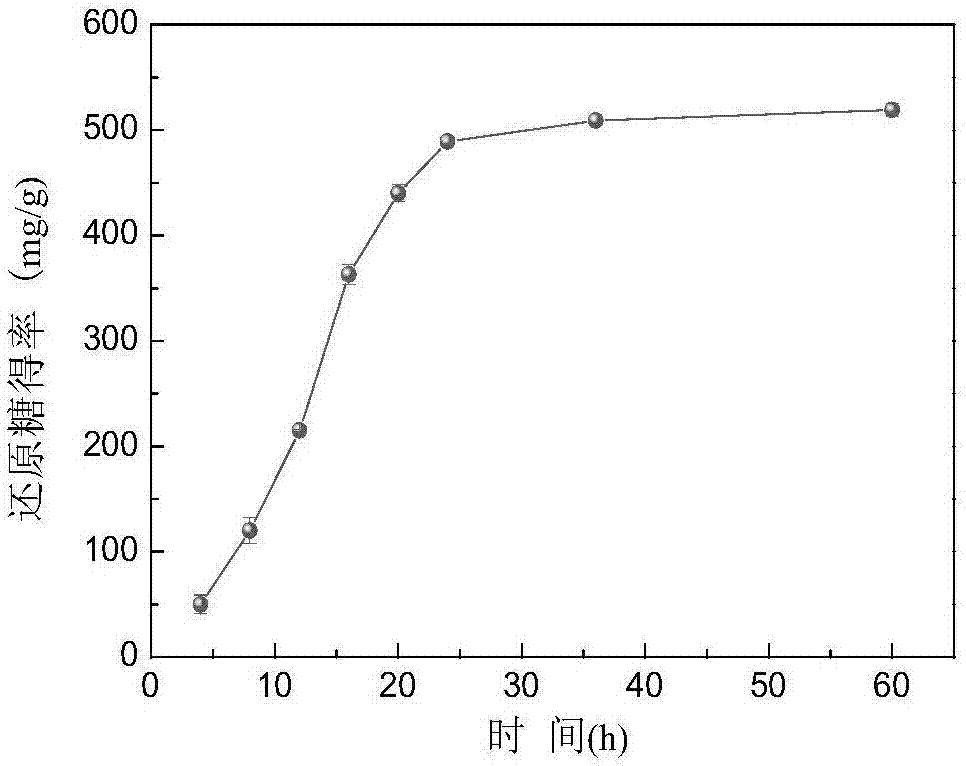

Method for producing konjac glucomannan

InactiveCN103060399AIncrease concentrationIncrease productivityFermentationHigh concentrationHydrolysate

The invention discloses a method for producing konjac glucomannan, which comprises the following steps: firstly, adding konjac flour into citric acid-sodium citrate buffer solution with pH of 6.0 to carry out enzymatic hydrolysis with beta-mannase for 2 to 6 h; carrying out heating treatment on enzymatic hydrolysate for 15 to 30 min by adopting a variable frequency microwave reactor; then placing the obtained enzymatic hydrolysate in a vacuum drying oven with the temperature of 45 DEG C for drying, and grinding and sieving the powder by 100 mesh sieves to obtain light yellow powder; and dissolving the light yellow powder in distilled water; and finally, executing the steps of centrifugation, vacuum evaporation and concentration, alcohol precipitation, drying, grinding and the like so as to obtain the konjac glucomannan finished product. According to the method disclosed by the invention, the enzymatic hydrolysis process adopts a semi-dry method; an enzymatic substrate has high concentration; production efficiency is greatly improved; and production cost is greatly reduced.

Owner:SOUTHWEST UNIVERSITY

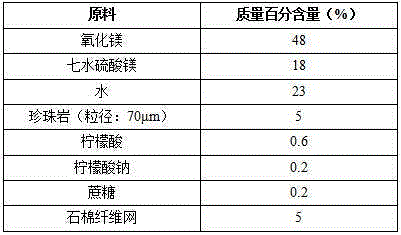

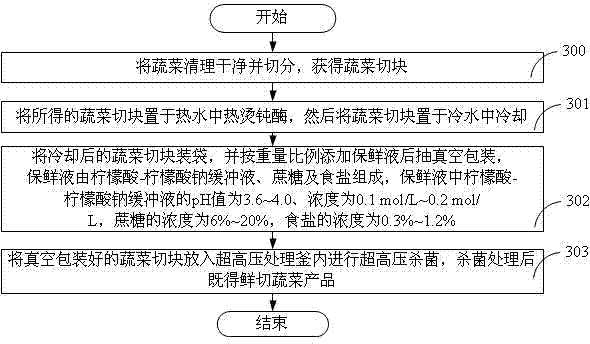

Fresh-cut vegetable processing method

InactiveCN103564034AMaintain nutritional qualityMaintain sensory qualityFruits/vegetable preservation by heatingUltra high pressureVegetable processing

A fresh-cut vegetable processing method comprises the following steps: cleaning up and cutting a vegetable to obtain vegetable blocks, putting the obtained vegetable blocks into hot water for blanching and enzyme inactivation, then putting the vegetable blocks into cold water for cooling, packaging the cooled vegetable blocks, adding a preservative solution according to the weight ratio, then conducting vacuum packaging, and carrying out ultra-high pressure processing on the vegetable blocks that are packaged in vacuum to obtain a fresh-cut vegetable product capable of being stored at the room temperature, wherein the preservative solution mainly comprises a citric acid-sodium citrate buffer solution, cane sugar and salt, the pH value of the citric acid-sodium citrate buffer solution in the preservative solution is 3.6-4.0, the concentration of the citric acid-sodium citrate buffer solution in the preservative solution is 0.1mol / L-0.2mol / L, the concentration of the cane sugar is 6%-20%, and the concentration of the salt is 0.3%-1.2%. According to the method, bacterial spores which are not killed by the ultra-high pressure technique in the fresh-cut vegetable product can be inhibited, and delicious taste of the fresh-cut vegetable is guaranteed.

Owner:NINGXIA UNIVERSITY

Deep-cleaning, antibacterial and tooth-protecting mouth wash based on chitosan derivatives and preparation method of mouth wash

InactiveCN106176546AWide range of raw materialsLow costCosmetic preparationsToilet preparationsOral diseasePropolis

The invention discloses a deep-cleaning, antibacterial and tooth-protecting mouth wash based on chitosan derivatives. The mouth wash is prepared from, by weight, 3% of chitosan derivatives, 5% of glycerol, 1.5% of xylitol, 2% of efficient solubilizer, 0.55% of citric acid, 0.3% of sodium citrate, 0.25% of malic acid, 0.12% of menthol, 0.15% of mint fragrance, 2% of propolis extracts, 3.5% of tea leaf extracts, 0.07% of caramel colour, 0.04% of saccharin sodium, 0.2% of chlorhexidine, 0.0003% of domiphen bromide and the balance deionized water. The invention provides the deep-cleaning, antibacterial and tooth-protecting mouth wash based on the chitosan derivatives and the preparation method of the mouth wash. The mouth wash prepared through the method has the functions of inhibiting bacteria, removing dental plaque and preventing oral ulcer, gingivitis and other oral diseases, and is good in antibacterial effect, quick in effect, free of toxic and side effects and comfortable in mouthfeel.

Owner:湖北立天生物工程有限公司

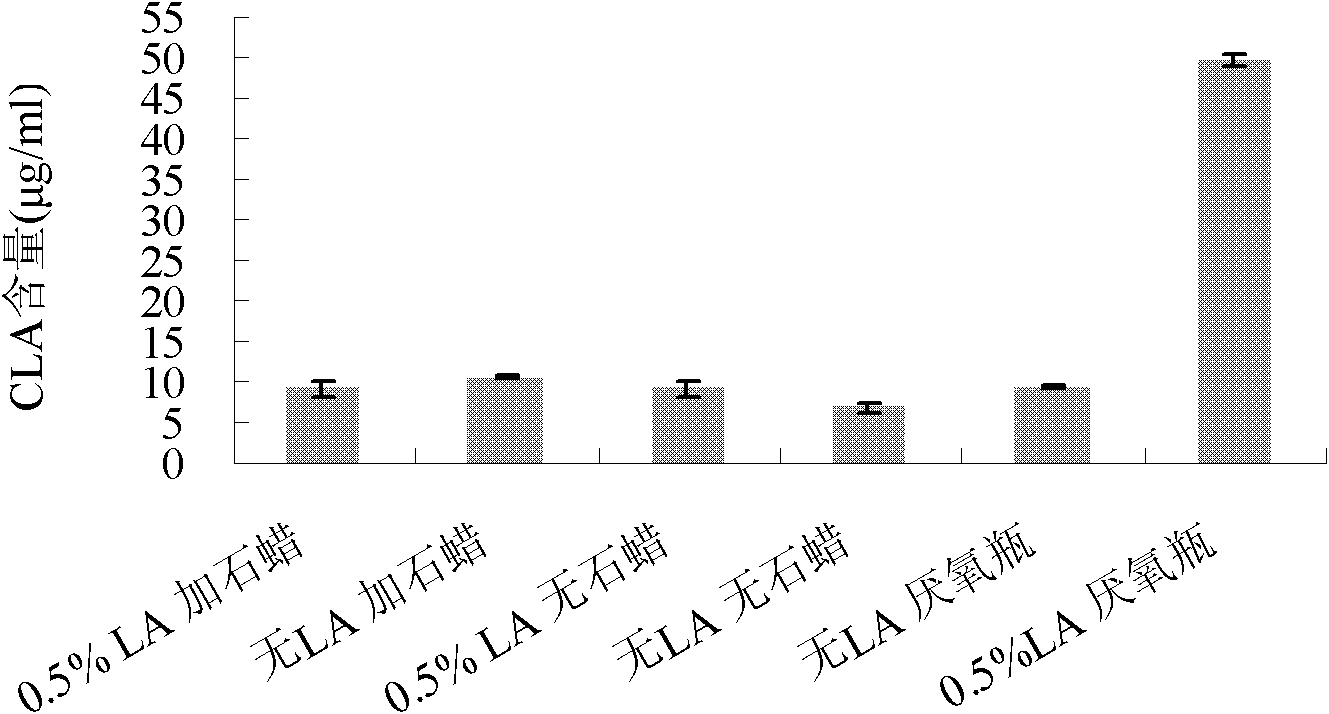

Method for bioconverting conjugated linoleic acid by using Lactobacillus plantarum

InactiveCN102206687AIncrease productionEasy to separateMicroorganism based processesFermentationBacteroidesCentrifugation

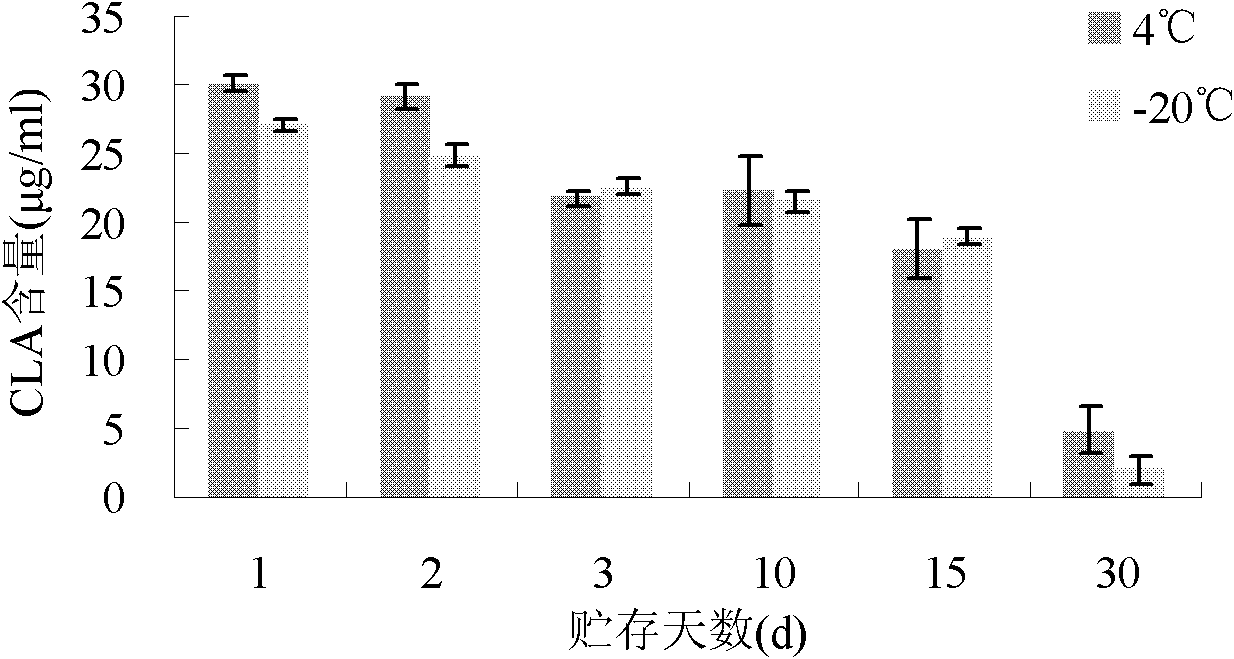

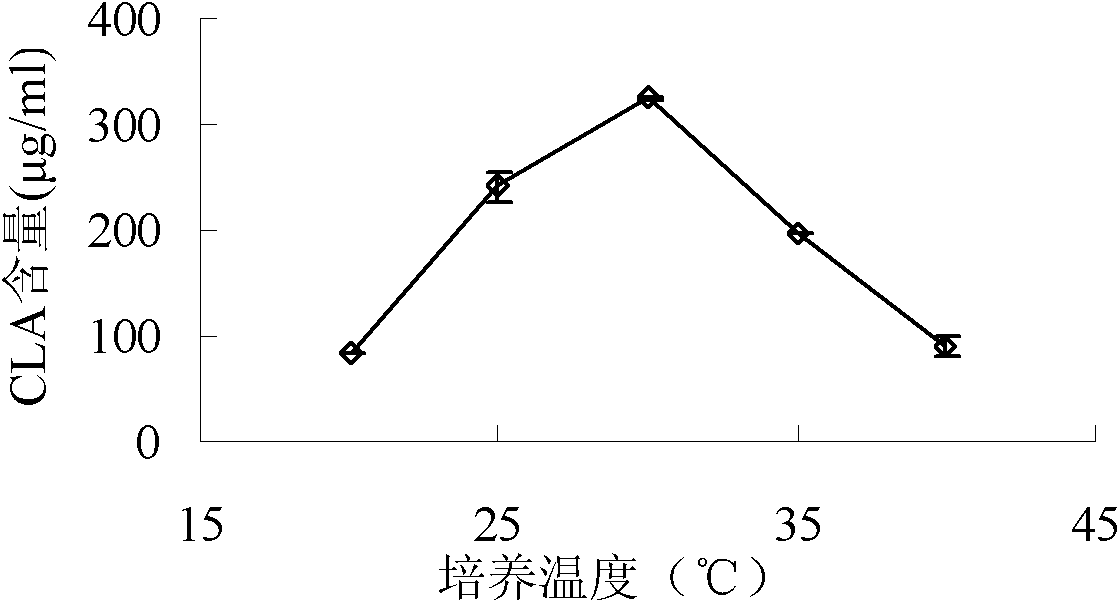

The invention discloses a method for bioconverting conjugated linoleic acid by using Lactobacillus plantarum, which comprises the following steps: inoculating Lactobacillus plantarum CGMCC NO.3785 to an MRS (Man, Rogosa and Sharpe) culture medium containing linoleic acid, preculturing, and carrying out refrigerated centrifugation to obtain resting cells; and inoculating the resting cells to a citric acid-sodium citrate buffer solution containing 3.0-25 mg / ml of linoleic acid, and carrying out shake culture for 84-120 hours. The method for converting LA (linoleic acid) into CLA (conjugated linoleic acid) does not need a high-temperature high-pressure environment, and the product can be separated conveniently; and the resting cells obtained by centrifugation are used for catalyzing the synthesis of CLA, thereby preventing the overhigh-concentration LA from inhibiting the growth of bacteria and further achieving the goal of high CLA yield.

Owner:ZHEJIANG UNIV

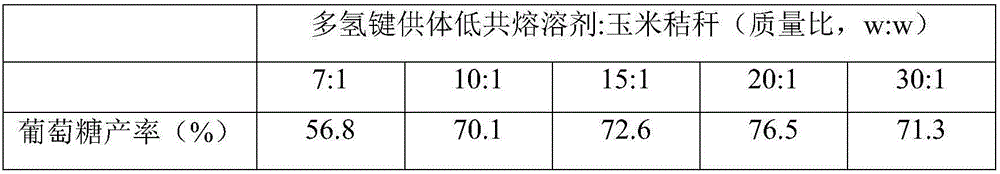

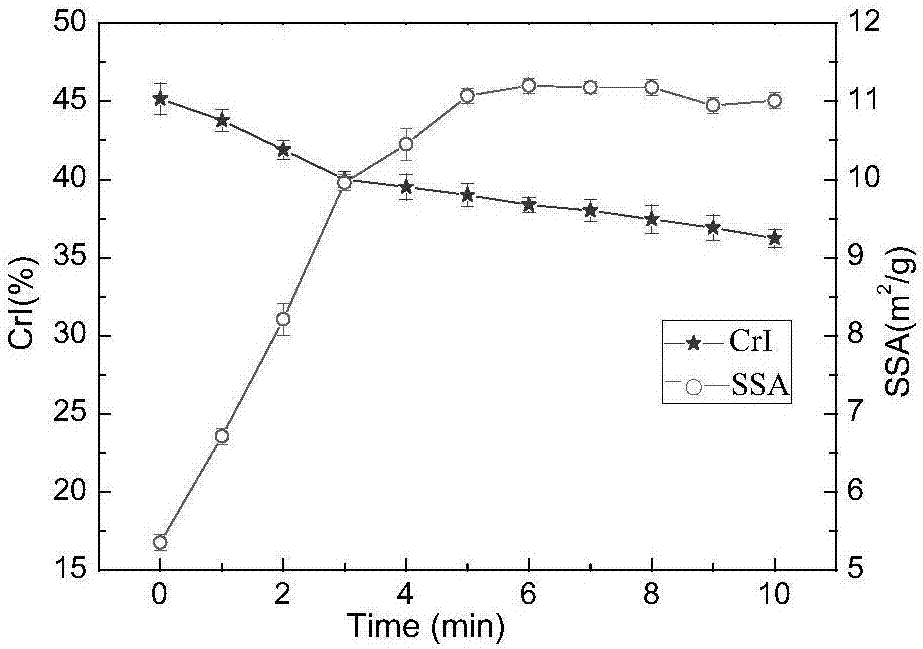

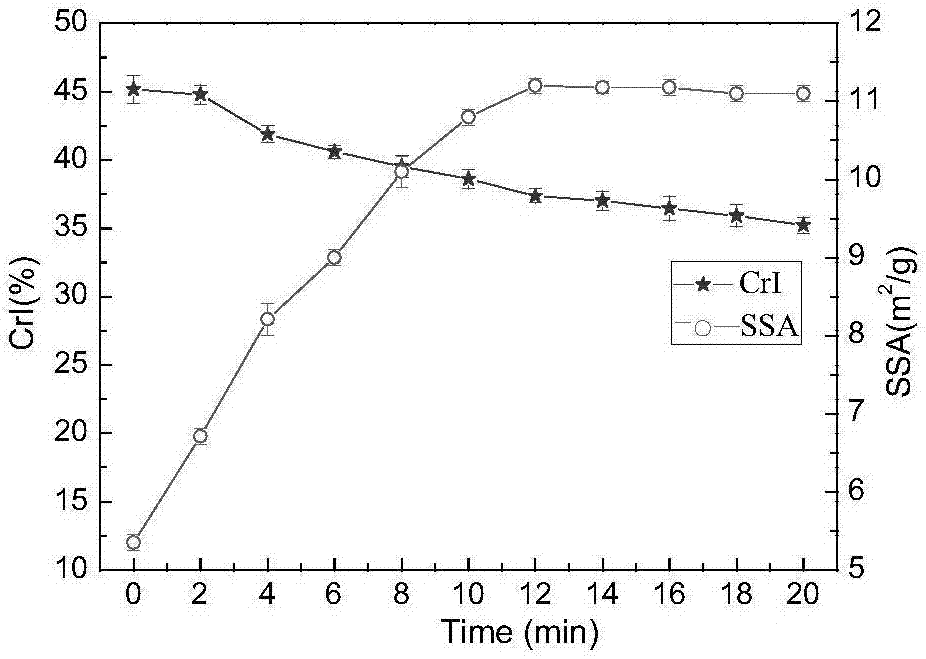

Maize straw pretreatment process adopting multi-hydrogen-bond-donor deep-eutectic solvent and recycling method of multi-hydrogen-bond-donor deep-eutectic solvent

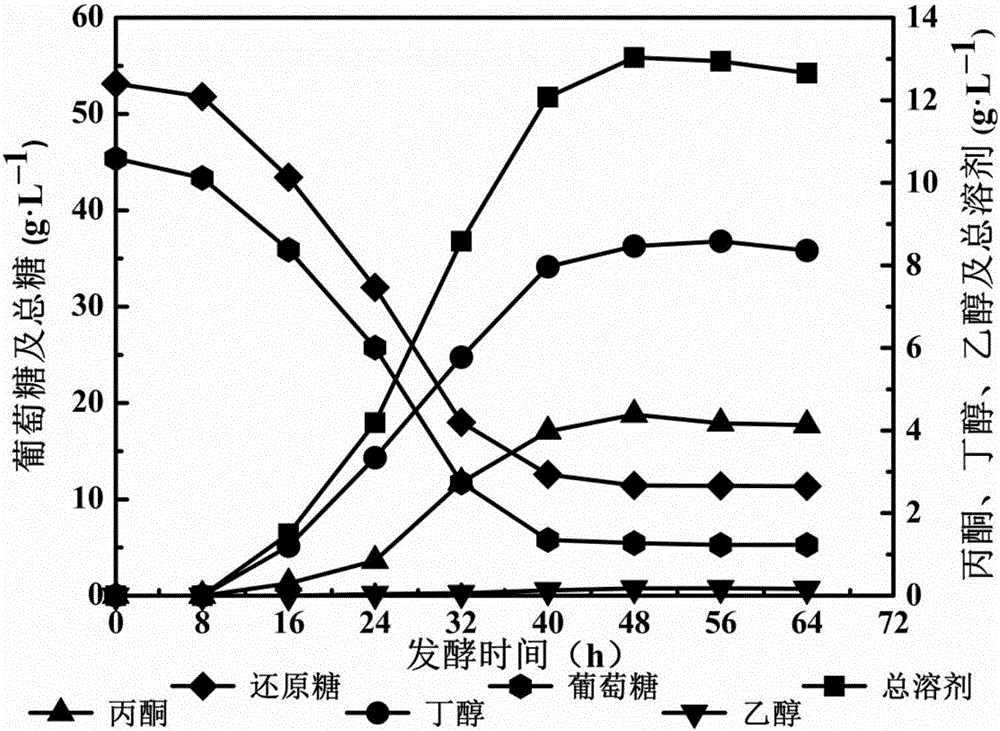

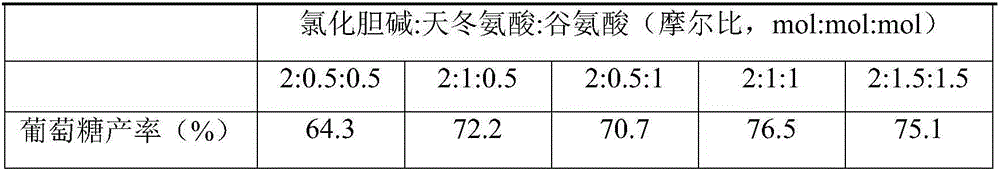

The invention relates to a maize straw pretreatment process adopting a multi-hydrogen-bond-donor deep-eutectic solvent and a recycling method of the multi-hydrogen-bond-donor deep-eutectic solvent, belonging to the field of chemical engineering. In a multi-hydrogen-bond-donor deep-eutectic solvent system composed of choline chloride, aspartic acid and glutamic acid, adding maize straw and pretreating the maize straw for 0.5-3 h at 90-130 DEG C, centrifuging the mixture, collecting the supernate, and washing the sediment for three times by adopting deionized water; adding a certain amount of maize straw into the supernate, carrying out pretreatment for certain time at certain temperature, and repeating the above steps; mixing the pretreated maize straw and citric acid-sodium citrate buffer solution at a certain solid-to-liquid ratio, and adding with cellulose for enzymolysis, wherein the final yield of glucose is greater than 76%, and after the multi-hydrogen-bond-donor deep-eutectic solvent is recycled for 4 times, the yield of glucose is greater than 65%. The process and the recycling method have the advantages that the process is simple, the efficiency is high, the procedure is economical, the discharge of industrial wastewater, waste gases and residues is little, etc., and the maize straw hydrolysate after pretreatment can be used for fermentation production of butanol.

Owner:JIANGNAN UNIV

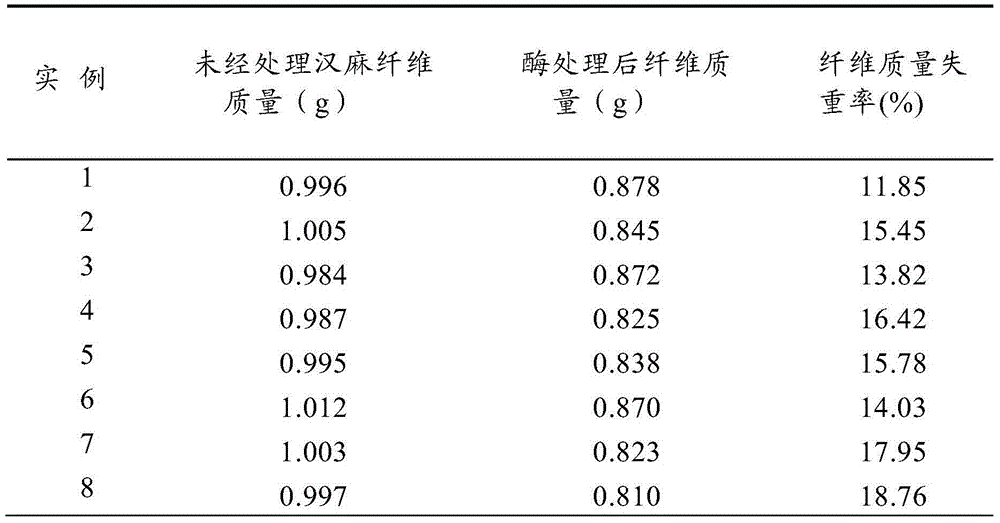

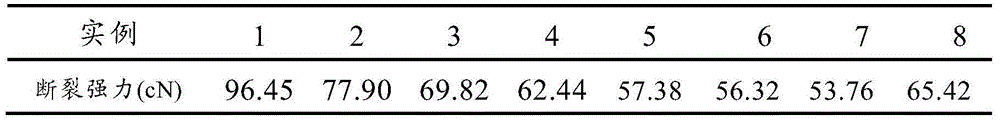

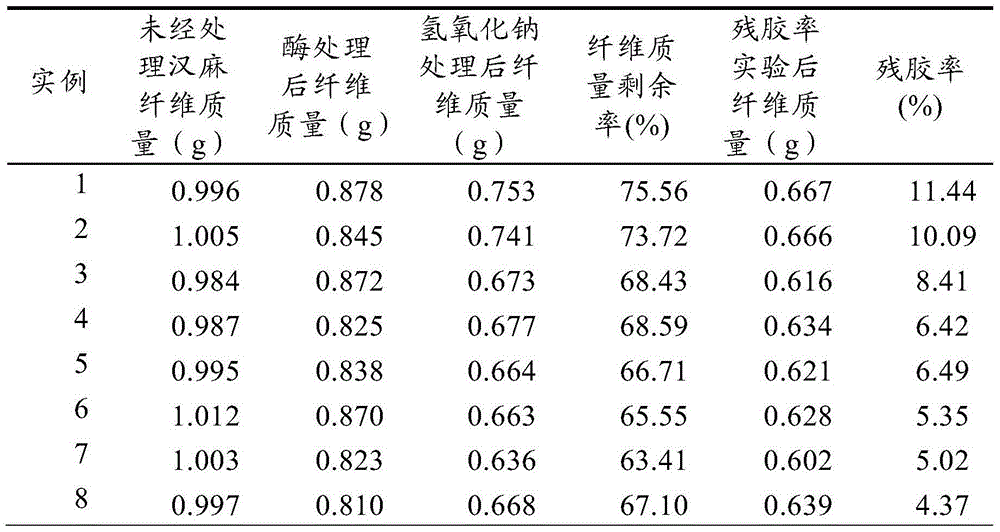

Method for degelatinizing hemp fiber with biological enzyme degelatinizing method combined with chemical degelatinizing method

The invention relates to a method for degelatinizing hemp fiber with the biological enzyme degelatinizing method combined with the chemical degelatinizing method. Citric acid-sodium citrate is used as a buffer solution; pectolase and zytase are used together for performing enzyme degelatinizing on hemp fiber; sodium hydroxide solution is used for performing secondary degelatinizing; through the two steps of degelatinizing, the high efficiency and specificity of pectolase are used for effectively removing most pectin in fiber; the effect of zytase is used for achieving a good effect of removing lignose when the sodium hydroxide solution is subjected to alkali scouring. The method provided by the invention realizes the effect that in the fiber degelatinizing process, acid is no longer used for performing pretreatment on fiber, so that the treatment of pretreatment wastewater is reduced; moreover, the biological enzyme degelatinizing method is remarkable in effect; when the method is adopted to performing degelatinizing on hemp fiber, relatively high breaking strength of the hemp fiber is ensured, the whiteness is also remarkably increased, use of sodium hydroxide is reduced, and discharge of scouring wastewater is reduced.

Owner:QIQIHAR UNIVERSITY

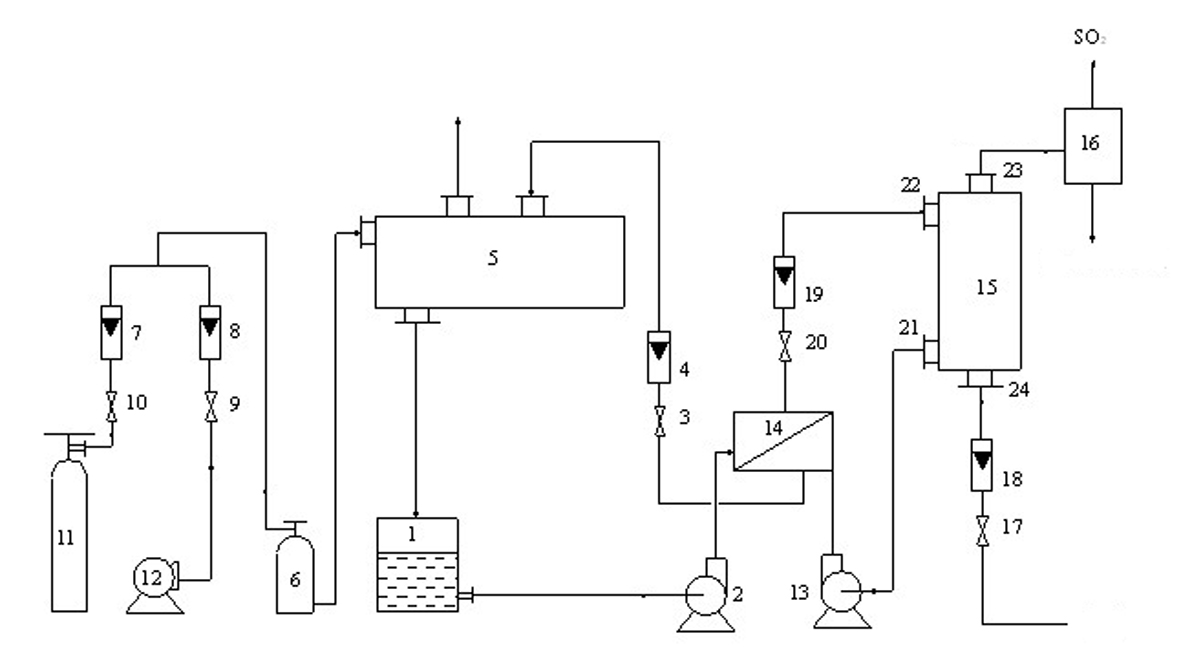

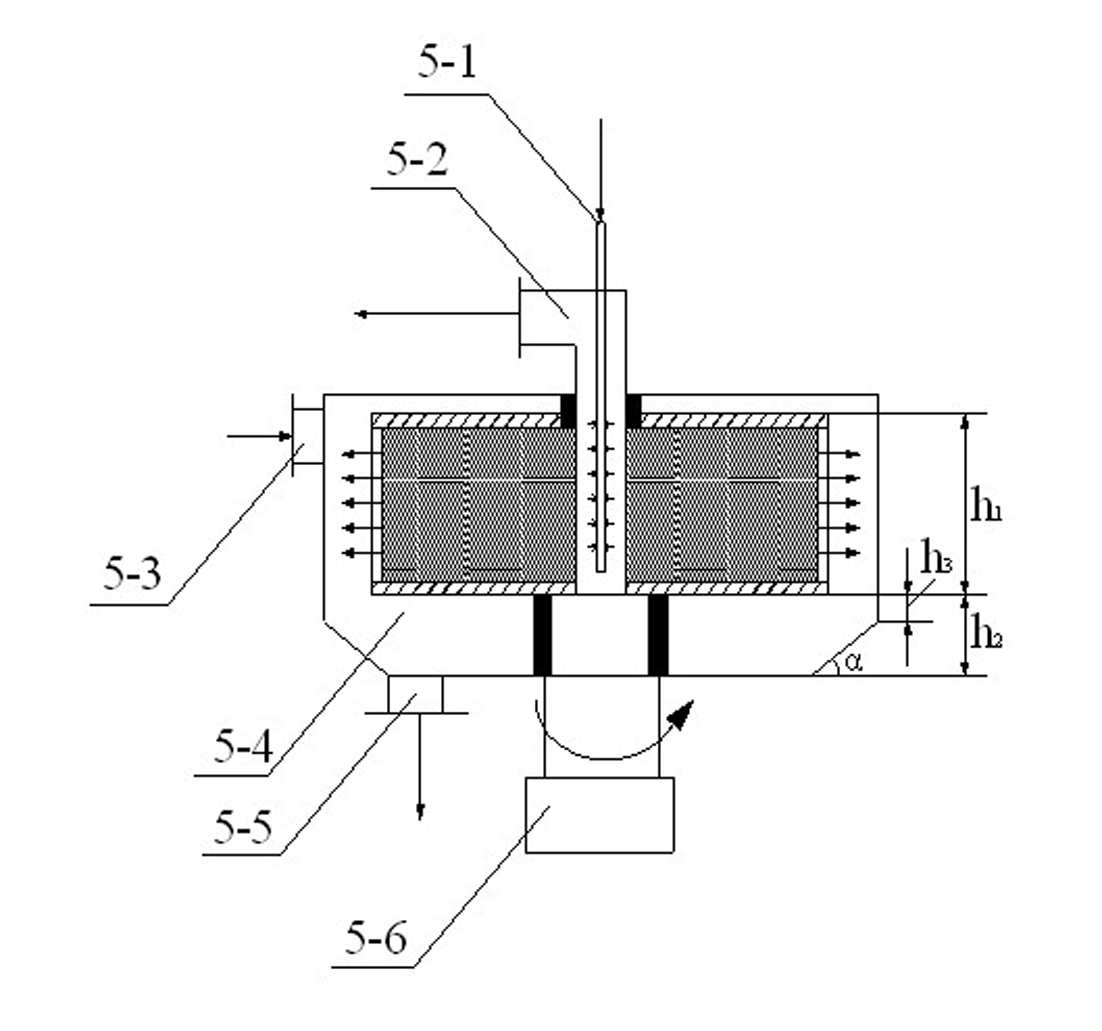

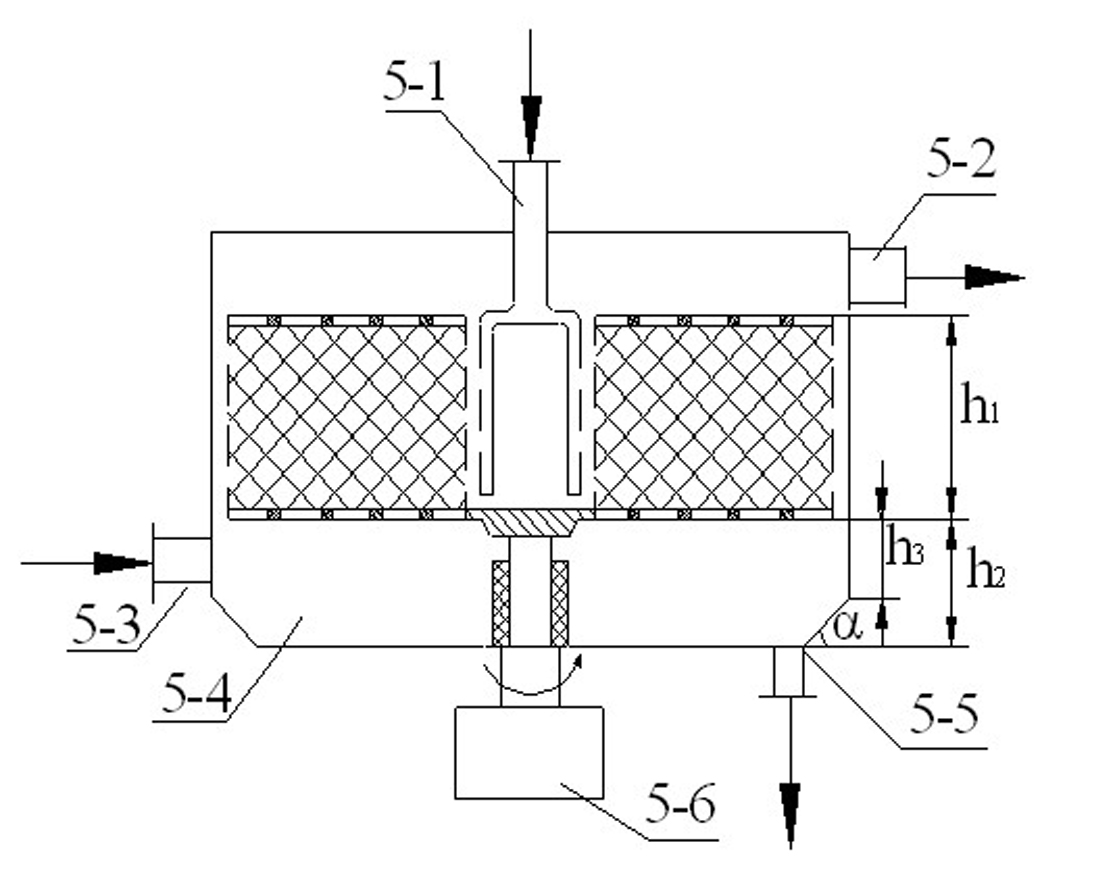

Method and device for removing low-concentration sulfur dioxide in flue gas

ActiveCN102019137AImprove mass transfer efficiencyQuick contact mixDispersed particle separationDesorptionGas phase

The invention belongs to the technical field of flue gas desulfurization, in particular to a method and device for removing low-concentration sulfur dioxide in flue gas, thereby solving the shortcomings in the existing flue gas desulfurization process. A citric acid-sodium citrate buffer solution is taken as an absorption solution, a rotary packed bed is taken as an absorption reactor, and the method comprises the steps of opening the rotary packed bed, leading the absorption solution and the flue gas containing the sulfur dioxide to enter into the rotary packed bed, leading a liquid phase and a gas phase to conduct the contact reaction, and leading the liquid phase after the reaction to enter into a desorption system for desorption. The device comprises the rotary packed bed, a gas inletof the rotary packed bed is connected with a source of the flue gas containing the sulfur dioxide, a liquid inlet of the rotary packed bed is connected with the source of the absorption solution, anda liquid outlet of the rotary packed bed is connected with the desorption system. By adopting the method, the desulfurization efficiency is high, the absorption solution is renewable, and the method can be flexibly used in an acid-making system or systems for producing sulfur and the like; furthermore, the device can reduce scale formation and blockage of the device, be conductive to improving the absorption efficiency and the desorption rate of the absorption solution and reduce the investment and the operation cost.

Owner:JIANGSU ZEYU ENVIRONMENTAL ENG

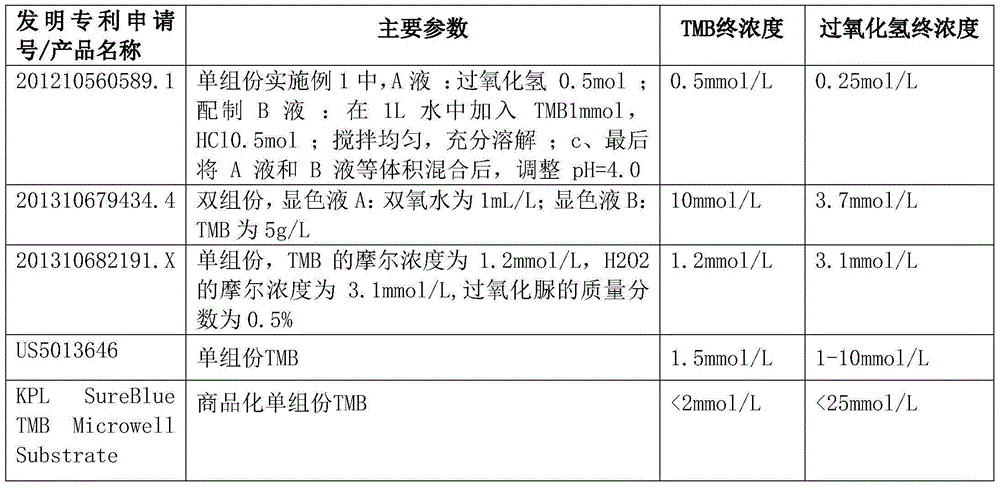

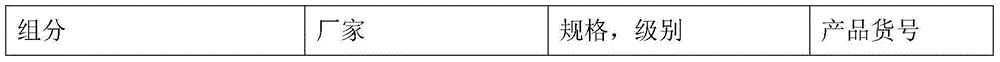

Single-component TMB coloration liquid and preparation method thereof

ActiveCN105116141AImprove solubilityGuaranteed stabilityMaterial analysisOrganic solventCarbamide peroxide

The present invention provides a single-component TMB coloration liquid, which is formed by mixing a liquid A and a liquid B, wherein urea hydrogen peroxide is dissolved in a citric acid-sodium citrate buffer liquid to prepare the liquid A, and polyvinyl alcohol, polyvinyl pyrrolidone, TMB and glycerol are dissolved in a citric acid-sodium citrate buffer liquid to prepare the liquid B. Compared with the single-component TMB coloration liquid in the prior art, the single-component TMB coloration liquid of the present invention has the following advantages that: the stability of the coloration substrate in the solution can be maintained, the operator can be protect from being away from organic solvent hazard, the damage on the environment can be reduced, the stable aqueous solution system can be formed, and the single-component TMB coloration liquid can be stored for 24 months at a temperature of 2-8 DEG C.

Owner:SHENZHEN WEIGUANG BIOLOGICAL PROD

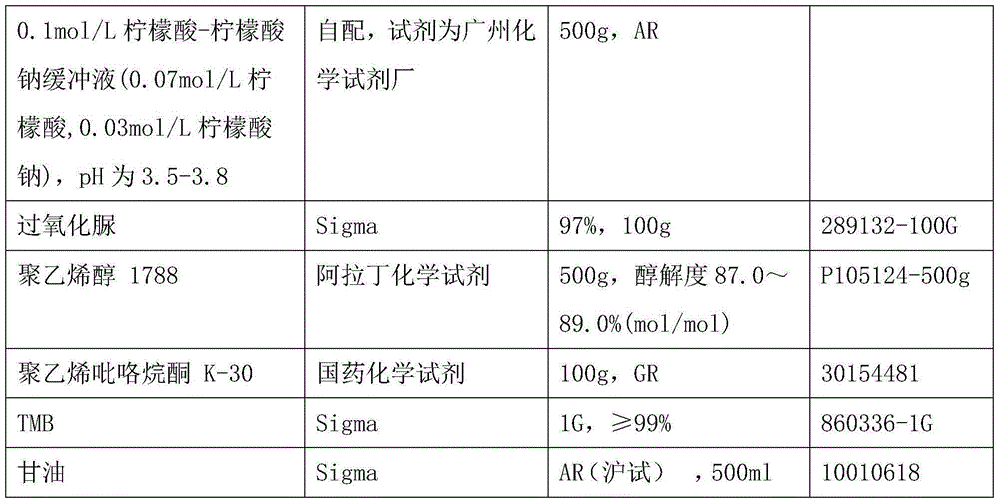

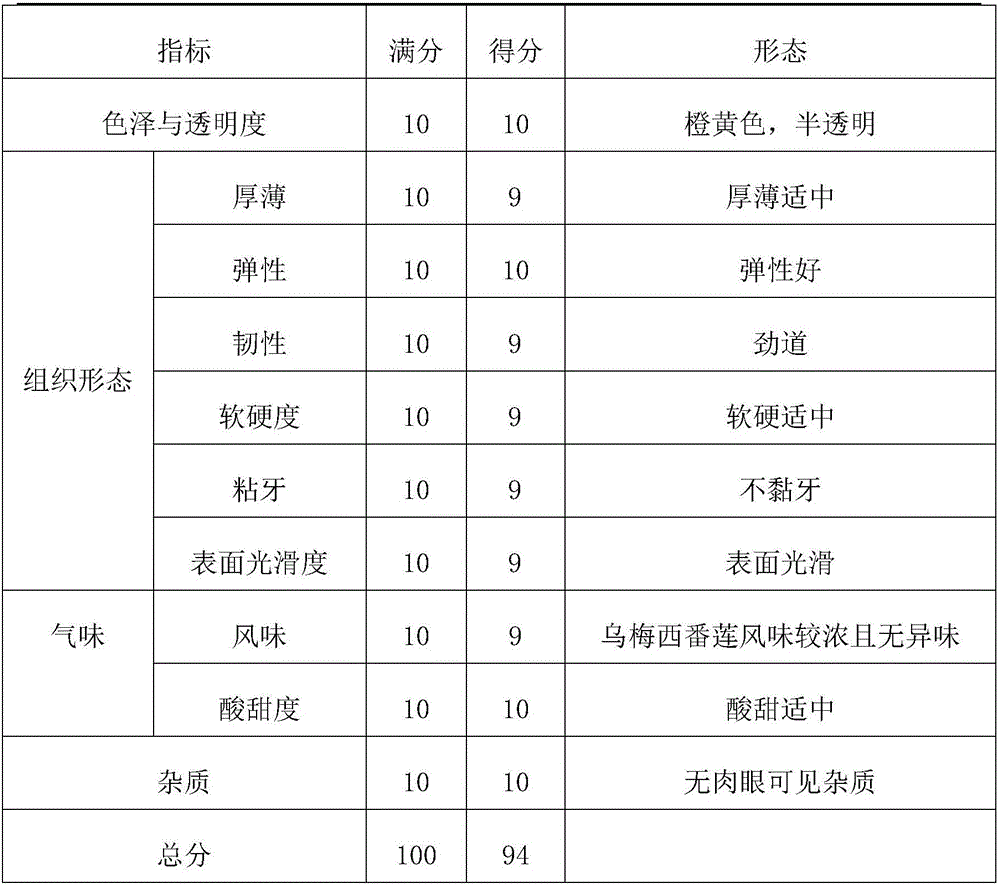

Compound ebony and passion fruit cake and preparation method thereof

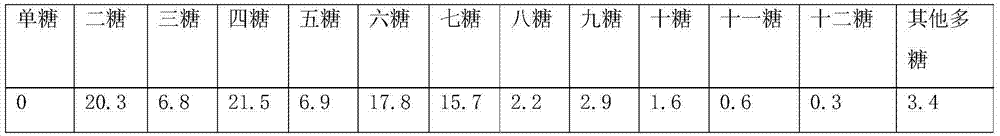

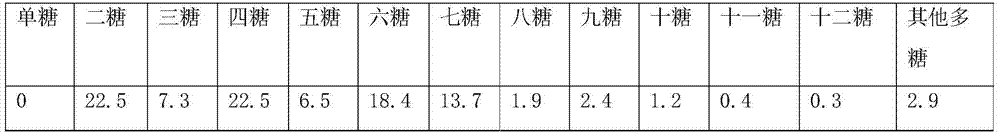

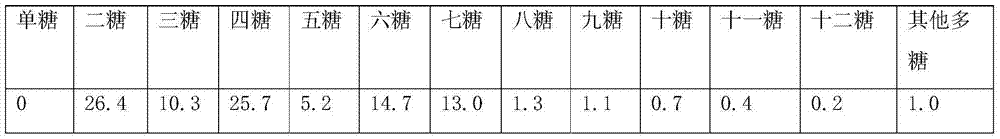

The invention relates to the technical field of food and processing, in particular to a compound ebony and passion fruit cake and a preparation method thereof. The compound ebony and passion fruit cake is prepared by 20-40% of ebony, 4-10% of passionflower, 15-40% of compound syrup, 0.6 to 2.0% of complex gum, 0.7 to 1.5% of citric acid and 0.03 to 0.07% of sodium citrate. The ebony and passionflower fruit cake produced by the invention contains 20-25% of total sugar, 5-10% of reducing sugar, 3-5% of sucrose, 14-18% of polysaccharide, and 75% of soluble solid content (higher than the national standard of 65%). The total sugar content is lower than that of the commercially available ebony fruit cake, the high maltose syrup is added in the production process, the sweetness is the same as that of sucrose, but the human body absorption capacity is small, therefore the fruit cake is suitable for a wider range of people.

Owner:XIHUA UNIV

Method for rapidly preparing galactomannan oligosaccharide enzymatic hydrolysate by utilizing guar gum

The invention discloses a method for rapidly preparing galactomannan oligosaccharide enzymatic hydrolysate by utilizing guar gum. The method is characterized by firstly preparing a guar gum solution with a citric acid-sodium citrate buffer solution, then controlling the temperature and time to carry out heating swelling, after cooling, adding beta-mannanase, xylanase and cellulase at the same time, fully mixing the materials uniformly and controlling the enzymolysis temperature and time to carry out degradation. The method has the effects of achieving rapid enzymolysis of guar gum at high concentration, obtaining the galactomannan oligosaccharide enzymatic hydrolysate and saving the drying and purifying costs during subsequent production of galactomannan oligosaccharide.

Owner:临沂小鲁生物科技有限公司

Honeysuckle flower green tea

InactiveCN101904389AImprove immunityHeat-clearing and detoxifyingTea extractionFood additiveBlood sugar

The invention discloses honeysuckle flower green tea which comprises the following raw materials of honeysuckle flower, green tea, licorice, white sugar and a food additive, wherein the food additive comprises citric acid and sodium citrate. The honeysuckle flower green tea of the invention has functions of refreshing brain, improving immunity, resisting virus, bacteria and inflammation, relieving fatigue, improving metabolism, lowering blood sugar and blood pressure, resisting ageing and cancer, preventing cancer, appetizing and protecting stomach. The honeysuckle flower green tea is golden yellow and has herb aroma and slight taste of traditional Chinese medicine. The honeysuckle flower green tea is sour, sweet and bitter and can be drunk as beverage as well as oral liquid without losing healthcare function thereof.

Owner:郑秀颀

Mixture of natural plant extracts and preparation method and application of mixture

InactiveCN102934644AEfficient killingEnsure safetyBiocideFruit and vegetables preservationBiotechnologyAnti bacterial

The invention relates to natural plant extracts, particularly relates to a mixture of natural plant extracts and a preparation method and application of the mixture and particularly discloses extracts of lemon eucalyptus, rosemary, liquorice, cinnamon and hyperforin perforatum and application of extracts in preparation of a disinfecting agent. Natural edible plant constituents serve as effective antibiotic constituents, other natural food additive constituents such as citric acid and sodium citrate are added to prepare the pure natural plant type disinfecting agent which is safe and nontoxic, and the disinfecting agent has the good preservation effect.

Owner:JIANGSU UNIV

Method for improving enzymatic hydrolysis efficiency of bamboo reed stalks

InactiveCN102888433AIncrease contact surfaceLow lignin contentFermentationEnzymatic hydrolysisCellulase

The invention discloses a method for improving enzymatic hydrolysis efficiency of bamboo reed stalks, comprising the steps of washing the bamboo reed stalks, cutting into short sections and drying for standby application, adding the bamboo reed stalks into mild alkali reaction solution to soak for pretreatment, filtering and washing the pretreated bamboo reed stalks to be neutral, drying and grinding for standby application, adding citric acid-sodium citrate buffer solution and cellulase in the grinded bamboo reed stalks to carry out enzymatic hydrolysis on the grinded bamboo reed stalks, carrying out centrifugal separation on the reaction solution after enzymatic hydrolysis, and taking the supernatant as the enzymatic hydrolysis product of the bamboo reed stalks. According to the method, pretreatment is carried out on ligno-cellulose raw material through a chemical method and the lignin is degraded and the crystalline texture of the cellulose is opened to enlarge the contact surface of the enzyme and the substrate, so that the lignin content in the stalks is considerably reduced, the reducing sugar conversion rate of the bamboo reed stalks after the enzymatic hydrolysis is improved and then the enzymatic hydrolysis efficiency is improved.

Owner:SOUTHWEST UNIVERSITY +1

Method for promoting enzymolysis saccharification of lignocellulose

The invention relates to a method for promoting enzymolysis saccharification of lignocellulose. The method comprises the steps of soaking hair in an acetic acid solution which is 85-95 DEG C firstly, regulating the pH value to be 6-7, conducting filtration, and drying filtrate to obtain hair protein powder; then smashing and screening lignocellulose biomass to obtain lignocellulose biomass powder; soaking the lignocellulose biomass powder in deionized water for irradiation treatment; extracting the lignocellulose biomass powder after irradiation treatment, adding a citric acid-sodium citrate buffer solution, conducting uniform mixing to obtain a mixed solution, and adding cellulose and the hair protein powder to the mixed solution to obtain enzymatic hydrolysate; and conducting enzymatic hydrolysis reaction on the enzymatic hydrolysate for 3-24 h at 30-45 DEG C to promote enzymolysis saccharification of lignocellulose. The structure of lignocellulose is changed through irradiation treatment to facilitate enzymolysis saccharification, the hair protein powder is used as an enzymolysis assistant, non-specificity absorption of cellulose by lignin is reduced, and higher efficiency can be realized within a shorter period of time.

Owner:YULIN UNIV

Method for rapidly preparing galactomannan oligosaccharide enzymatic hydrolysate by utilizing high-concentration guar gum solution

The invention discloses a method for rapidly preparing galactomannan oligosaccharide enzymatic hydrolysate by utilizing a high-concentration guar gum solution. The method is characterized by firstly preparing a guar gum solution with a citric acid-sodium citrate buffer solution, then controlling the temperature and time to carry out heating swelling, after cooling, adding beta-mannanase, xylanase and endoglucanase at the same time, fully mixing the materials uniformly and controlling the enzymolysis temperature and time to carry out degradation. The method has the effects of achieving rapid enzymolysis of guar gum at high concentration, obtaining the galactomannan oligosaccharide enzymatic hydrolysate and saving the drying and purifying costs during subsequent production of galactomannan oligosaccharide.

Owner:QINGZHOU RONMER BIOLOGY TECH CO LTD

Method for extracting maize germ oil by adopting ultrasonic-assisted aqueous enzymatic method

InactiveCN104745286ANo residueReduce usageFatty-oils/fats refiningFatty-oils/fats productionWater bathsCellulose

The invention relates to a method for extracting maize germ oil by adopting an ultrasonic-assisted aqueous enzymatic method. The method for extracting the maize germ oil by adopting the ultrasonic-assisted aqueous enzymatic method is characterized by comprising the following steps: smashing maize germs taken as a raw material, sieving, then adding citric acid-sodium citrate buffer solution, and carrying out ultrasonic pretreatment; cooling, regulating pH value, then adding cellulose and alpha-amylase, stirring in constant-temperature water bath, and carrying out enzymatic hydrolysis; after the enzymatic hydrolysis is finished, deactivating enzymes, cooling to room temperature, centrifuging a sample, collecting supernate, demulsifying emulsion, centrifuging secondarily, then separating supernate, and mixing the supernates, so that the maize germ oil is obtained. The method for extracting the maize germ oil by adopting the ultrasonic-assisted aqueous enzymatic method has the advantages of mild conditions, high oil yield, no pollution, easy operation, safety, rapidness and applicability of large-scale production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for extracting beet pectin by using protopectinase

The invention discloses a method for extracting beet pectin by using protopectinase. The method comprises the following steps: 1, weighing 10kg of 80 mesh beet pulp, adding water with the amount 5-10 times the mass of beet pulp, carrying out immersion washing at 80-90DEG C for 5-15min to remove soluble sugar and impurities and passivate enzymes in the beet pulp, and filtering by using gauze to obtain wet beet pulp; 2, adding 100-300L of a citric acid-sodium citrate buffer solution with the pH value of 4.0-6.0 to the wet beet pulp, adding 1-2.5L of a crude protopectinase solution, and reacting at 40-70DEG C under 150rpm for 2-4h; 3, sequentially respectively carrying out plate and frame filtration and filter core filtration on a pectin extraction liquid to obtain a pectin stock solution, wherein a plate and frame filter has 20 layers of a filter membrane, the filtration precision of the plate and frame filter is 20[mu]m, a filter core filter is a PP folding-20-3 type filter core filter, and the precision of the filter core filter is 0.1[mu]m; 4, carrying out concentrating filtration on the filtered pectin stock solution through using a 8-tube tubular ultrafilter membrane to thoroughly remove impurities and concentrate the pectin stock solution to 3-5%; and 5, drying the concentrated and impurity-removed pectin stock solution through using an experimental high-speed centrifugal spray drier.

Owner:常州毅博生物科技有限公司

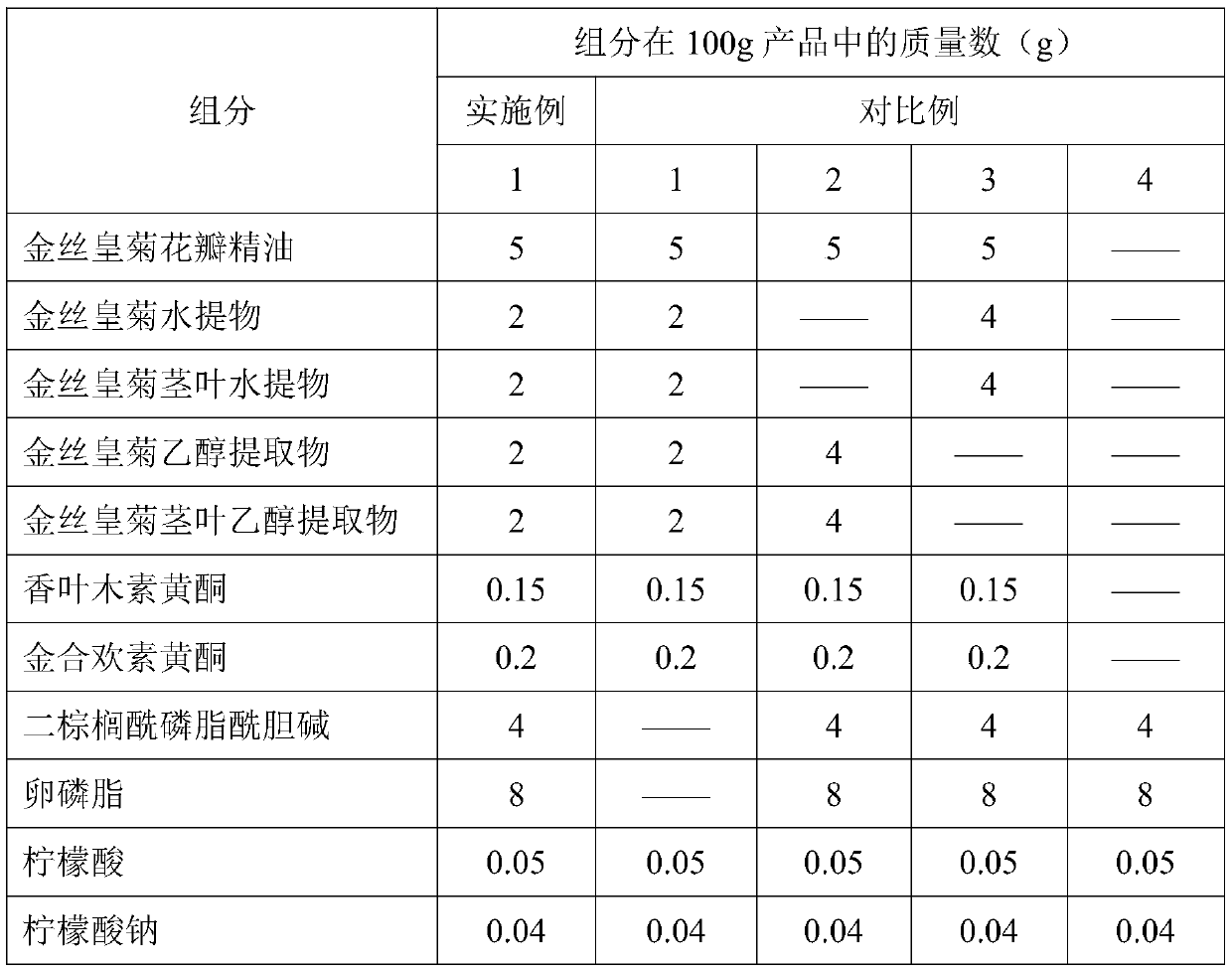

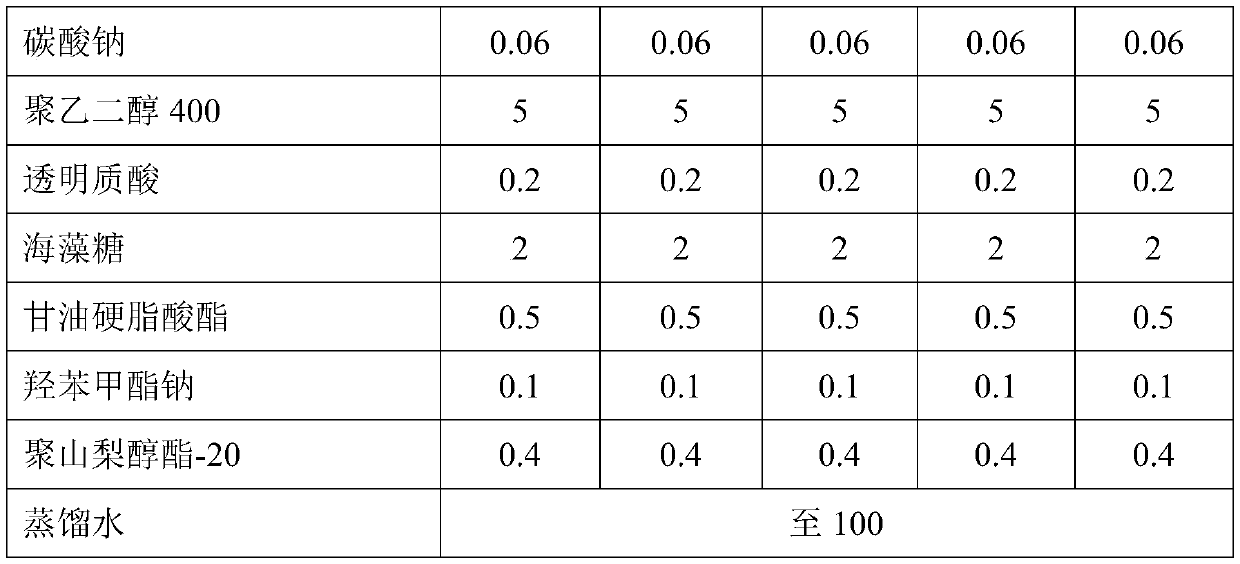

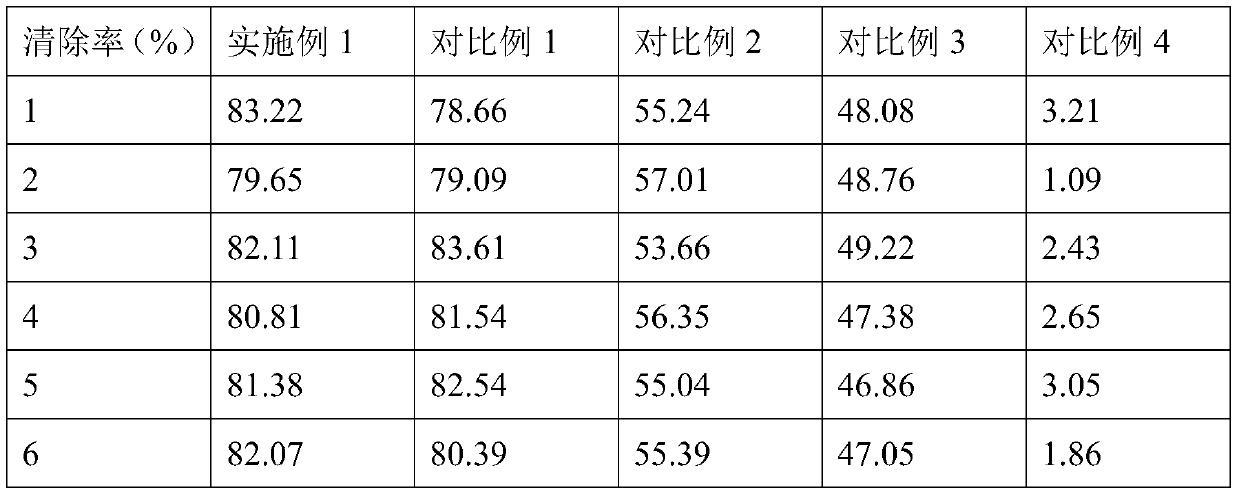

Dendranthema morifolium nanotechnology skin care product and preparation method and application thereof

ActiveCN111481481AUltimate skin care effectOptimal Screening of Nanotechnology Process ParametersCosmetic preparationsAntipyreticAcacetinPolyethylene glycol

The invention relates to a Dendranthema morifolium nanotechnology skin care product which is composed of the following raw materials: Dendranthema morifolium petal essential oil, a Dendranthema morifolium aqueous extract, a Dendranthema morifolium alcohol extract, a Dendranthema morifolium stem and leaf aqueous extract, a Dendranthema morifolium stem and leaf alcohol extract, and diosmetin and acacetin flavones separated from Dendranthema morifolium; dipalmitoyl phosphatidylcholine, lecithin, polyethylene glycol 400, hyaluronic acid, trehalose, glyceryl stearate, sodium methyl hydroxybenzoate,polysorbate-20, citric acid, sodium citrate, sodium carbonate and distilled water supplemented to 100 parts. According to the nanotechnology skin care product added with multiple active ingredients of Dendranthema morifolium, multiple components and proportions are reasonably and scientifically designed, nanotechnology process parameters are optimized and screened, and the skin care effect of Dendranthema morifolium is brought into play to the maximum extent.

Owner:江苏灵源沂岸科技股份有限公司

Antrodia mycelium flavor soft sweet and processing method thereof

The invention relates to an antrodia mycelium flavor soft sweet and a processing method thereof. The main raw material comprises the following components by mass: 10%-27% of fresh antrodia mycelium, 10%-20% of white granulated sugar, 0-20% of glucose syrup, 16%-30% of isomalto oligosaccharide, 20%-30% of malt dextrin, 2%-6% of agar and 1%-3% of carrageenan, and accessories (taking the total weight of the main raw material as a basis for calculating) comprise 0.1%-0.3% of citric acid, 0.5%-2% of Vc, 0.2%-0.8% of sodium citrate and 0.02%-0.1% of potassium sorbate, before the end of sugaring off, when the sugar paste concentration is 75%, antrodia mycelium pellet is added for forming and drying. The characteristics of the processing method is scientific adding of the fresh antrodia mycelium and the isomalto oligosaccharide, the health function of the soft sweet is increased, the soft sweet quality is improved, the amount of added sugar is reduced, the antrodia mycelium flavor soft sweet is suitable for the majority of people to eat, expands consumer groups, and can meet the needs of consumer groups in the elderly.

Owner:FUJIAN AGRI & FORESTRY UNIV

Production method of instant nutritious purple sweet potato beverage powder

The invention provides a production method of instant nutritious purple sweet potato beverage powder. The production method of the instant nutritious purple sweet potato beverage powder comprises the following steps: (1) sorting, cleaning and peeling purple sweet potatoes; (2) cutting the processed purple sweet potatoes into small pieces being 2-3cm<3>; (3) protecting the color, rinsing and pulping by 4-6% an edible salt solution; (4) carrying out enzymolysis by 0.5-5% compound enzyme at 40-50 DEG C with the pH value being 5.0-6.0 for 1.0-1.5 hours; (5) filtering so as to obtain clear liquid, adding 2-10% of white sugar, 0.1-0.3% of citric acid, 0.1-0.3% of sodium citrate, 0.1-0.3% of pectin and 0.8-1.2% of granulesten, and blending; (6) stirring, carrying out homogenization under the pressure of 500-1000bar, controlling the feeding speed to be 5-1ml / min, and carrying out centrifugal spraying to form powder at the air inlet temperature of 160-220 DEG C and the air outlet temperature of 60-80 DEG C; and (7) packaging the powder into bags, thereby obtaining the instant nutritious purple sweet potato beverage powder. According to the production method, the process is simple; the using amount of amylase and saccharifying enzyme is low; the average relative molecular weight of the instant nutritious purple sweet potato beverage powder is relatively low; the soluble sugar is high in content, and is soluble instantly when being brewed by water; the instant nutritious purple sweet potato beverage powder is bright in color, high in nutritional value, high in market potential, and obvious in economic benefits, and has a large development space.

Owner:NANJING FEIMA FOOD

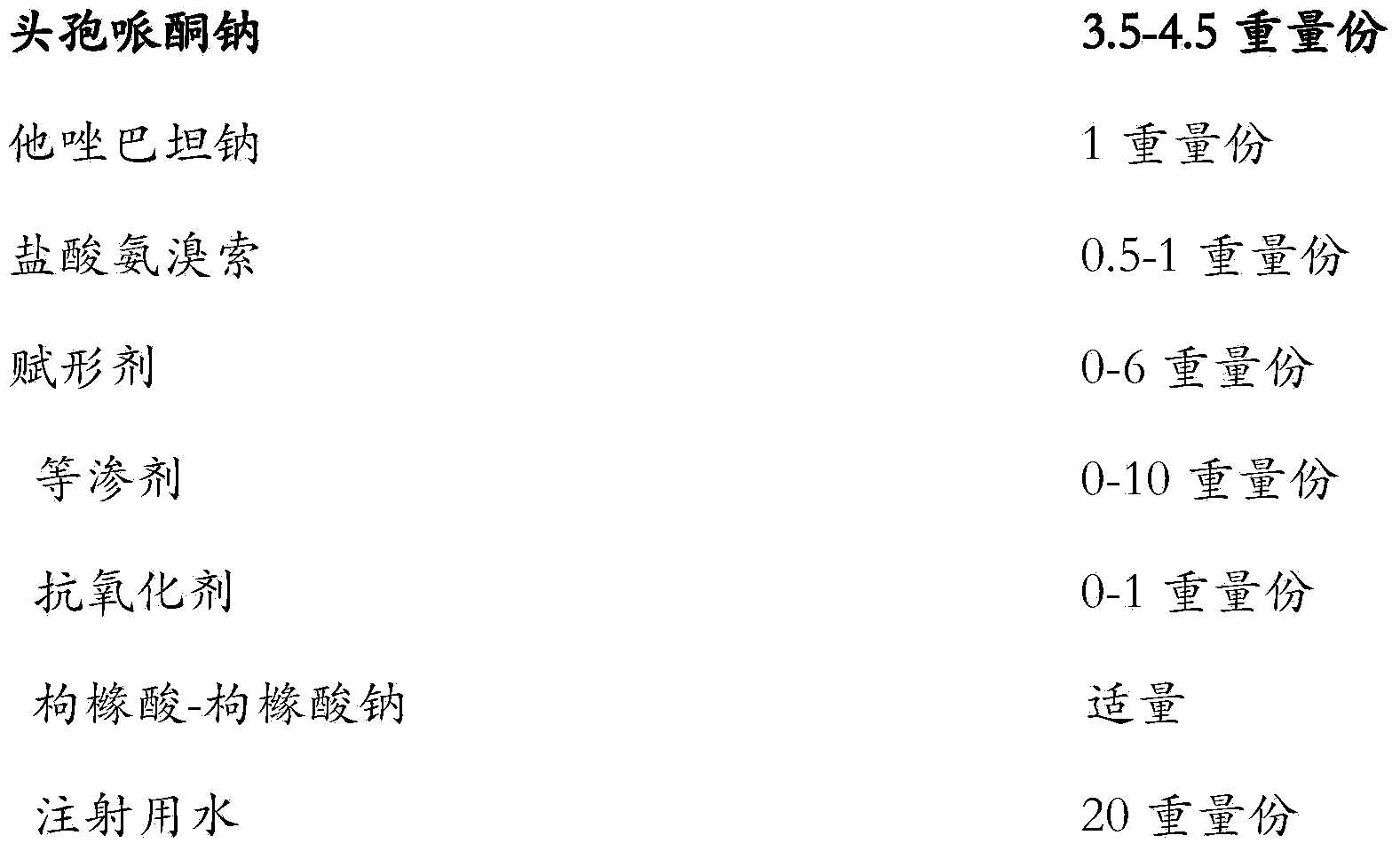

Composite pharmaceutical composition of cefoperazone sodium and tazobactam sodium and preparation process thereof

ActiveCN104013629AImprove solubilityImprove stabilityAntibacterial agentsRespiratory disorderSolubilityAntioxidant

The invention discloses a composite pharmaceutical composition of cefoperazone sodium and tazobactam sodium. The composite pharmaceutical composition is an injection, and is prepared from the following components in parts by weight: 3.5-4.5 parts of cefoperazone sodium, 1 part of tazobactam sodium, 0.5-1 part of ambroxol hydrochloride, 0-6 parts of excipient, 0-10 parts of isotonic agent, 0-1 part of antioxidant, a proper amount of citric acid-sodium citrate and 20 parts of injection water. The composite preparation of the cefoperazone sodium and the tazobactam sodium disclosed by the invention is stable in quality and significant in curative effect, not only can three active ingredients be evenly mixed, but also the composite pharmaceutical composition is excellent in stability, good in solubleness and good in clinical use safety.

Owner:福安药业集团庆余堂制药有限公司

Method for preparing guar gum oligogalactomannan enzymolysis solution by composite enzyme process

The invention discloses a method for preparing a guar gum oligogalactomannan enzymolysis solution by a composite enzyme process, which comprises the following steps: thoroughly mixing guar gum powder with beta-mannase, endoglucanase and cellobiase; adding a citric acid-sodium citrate buffer solution to prepare a mixed solution of the guar gum and three enzymes; and after the guar gum swells, controlling the enzymolysis temperature and time to perform enzymolysis. The method implements simultaneous enzymolysis of the three composite enzymes, omits the purification step after sequential degradation of single enzymes, saves the production time and cost and enhances the efficiency. The method implements enzymolysis of the guar gum under high-concentration conditions, obtains the oligogalactomannan enzymolysis solution, and saves the dehydration and drying cost of the subsequent oligogalactomannan production process.

Owner:QINGZHOU RONMER BIOLOGY TECH CO LTD

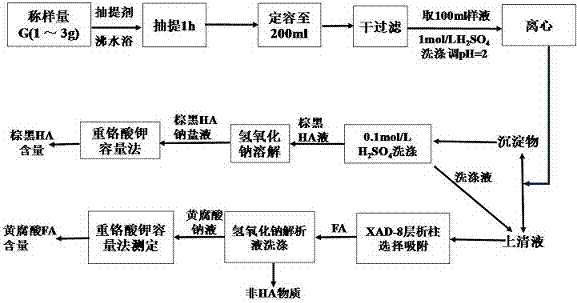

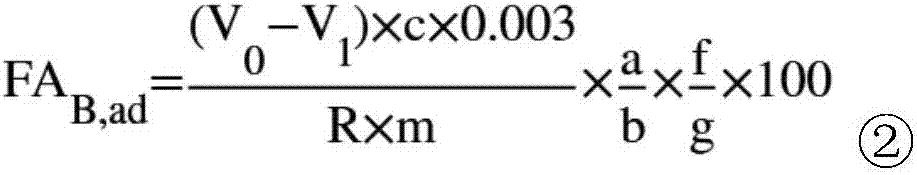

Determination method of activated humic acid

ActiveCN107063823AThe measurement result is smallThe measurement result is accurateChemical analysis using titrationPreparing sample for investigationPotassium dichromateDissolution

The invention provides a determination method of activated humic acid, and particularly relates to an activated humic acid content determination method of humic acid composite fertilizer, humic acid compound fertilizer, and humic-acid-contained compound fertilizer; the activated humic acid includes activated brownish black humic acid and activated fulvic acid, wherein the content of the activated brownish black humic acid is determined by a method of dissolution of citric acid-sodium citrate mixing fluid, acid settlement, alkali dissolution, and then by potassium dichromate oxidization; the content of activated fulvic acid is determined by a method of dissolution of citric acid-sodium citrate mixing fluid, acid settlement, filter liquid resin absorption, NaOH absorption, and potassium dichromate oxidization; the sum of the tested contents of activated brownish black humic acid and activated fulvic acid is the content of humic acid. The method has the advantages of being simple in operation, high in accuracy, and capable of meeting the operation demand of the most enterprises and quality inspection units while controlling the testing bias well.

Owner:SHANDONG AGRI UNIV FERTILIZER TECH CO LTD

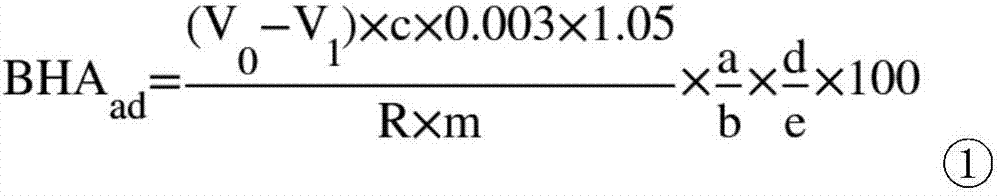

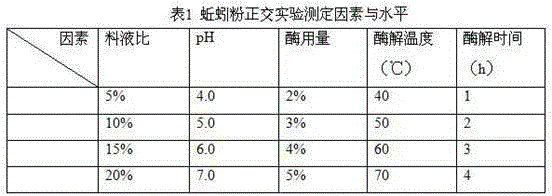

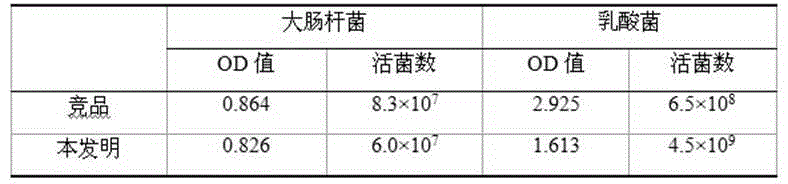

Method for preparing peptone from enzymatically-hydrolyzed earthworm dry powder and purpose of peptone

InactiveCN104593456AHigh in proteinRich varietyBacteriaFermentationEscherichia coliAmino acid composition

A provided method for preparing peptone from an enzymatically-hydrolyzed earthworm dry powder comprises: (1) getting earthworm powder, under the condition of 45 DEG C-55 DEG C, utilizing a Soxhlet extraction system to perform extraction for 25-30 min and leaching for 25-30 min by using petroleum ether, and drying to obtain degreased earthworm powder; and (2) adding the degreased earthworm powder into a citric acid-sodium citrate buffer with pH of 4-8, heating to 40 DEG C-80 DEG C, adding trypsin accounting for 2%-5% by weight of the earthworm powder for enzymatic hydrolysis for 1-4 h, after enzymatic hydrolysis is finished, performing enzyme deactivation on the solution at 90 DEG C-100 DEG C for 15-20 min, centrifuging, adjusting pH of the supernatant obtained through centrifugation to be 5.5-7.5, and performing reduced-pressure drying, so as to obtain peptone dry powder. The method does not destroy amino acid compositions in earthworm powder, and is simple in technological operation, high in hydrolysis efficiency and small in environmental pollution. The prepared peptone has good effect when being applied to culture escherichia coli and lactic acid bacterium, and is applicable as a microbe medium.

Owner:高向阳

Sweet potato food and method for processing same

InactiveCN101731539AKeep the flavorMaintain nutrientsFood preparationBiotechnologyFlavoring essences

The invention discloses sweet potato food and a method for processing the same. The sweet potato food comprises the following raw materials in part by weight: 30 to 80 parts of malt syrup, 3 to 25 parts of sweet potato powder or 20 to 60 parts of smashed sweet potato, 0 to 50 parts of white granulated sugar, 4 to 30 parts of edible gum, 0.1 to 2 parts of citric acid, 0.1 to 2 parts of sodium citrate, 0 to 5 part of food color, and 0 to 2 parts of flavoring essence. The preparation method comprises the following steps of: preparing the sweet potato powder or smashed sweet potato, adding the sweet potato powder or smashed sweet potato, dissolved edible gum, citric acid and sodium citrate to the syrup, mixing and decocting the mixture, and adding the edible color and flavoring essence to the mixture; and performing shaping, cooling and drying. The sweet potato powder or smashed sweet potato prepared by the method keeps the unique flavor and nutrients of the sweet potatoes, has good re-processing property and can be kept for a long time; the sweet potato food prepared by the formula and the process technique is good in taste and toughness, does not stick to a tooth, has strong aroma and keeps the nutrients in the sweet potatoes to a large extent.

Owner:SICHUAN BAI JIA FOOD CO LTD

Preparation method of pine needle flavone

InactiveCN103505479AAbundant and easy to get raw materialsLow costAntinoxious agentsConiferophyta medical ingredientsDPPHSolvent

The invention discloses a preparation method of pine needle flavone, which comprises the steps that pine needle drying powder is added to a citric acid-sodium citrate buffer solution; ultrasonic enzymolysis is performed by cellulase; hemicellulase is added for the ultrasonic enzymolysis; high-temperature inactivation is performed; an alcohol aqueous solution is added for extraction; the alcohol-containing final mass concentration of an obtained extracting solution after the alcohol aqueous solution is added is 50%; the extraction is performed for 90-150min at 70-90 DEG C; centrifugation and filtering are performed; a filtrate is concentrated; a solvent is removed; and pine needle flavone is prepared. According to the preparation method, a yield of a natural flavonoid substance obtained after pine needle with the particle size of 150-200 meshes is prepared by sequential cellulase and hemicellulase treatment and an ultrasonic technology; an antioxidation effect is good; an extraction yield can reach 73.86mg / g; and the hydroxy radical and DPPH (1,1-diphenyl-2-picrylhydrazyl radical) scavenging capacity and the reducing capacity are approximate to VC (vinyl chloride) with the same concentration.

Owner:CHINA JILIANG UNIV

Method for promoting enzymolysis of cellulose

InactiveCN105734095AWill not polluteIncreased reducing sugar contentFermentationHydrolysateCellulase

The invention discloses a method for promoting enzymolysis of cellulose. The method comprises the following steps: (1) adding 1-hexadecyl chloropyridine salt and 1,2-propylene glycol into a citric acid-sodium citrate buffer solution with a certain pH value; (2) adding cellulase into the solution obtained in the step (1); and (3) adding cellulose into the solution obtained in the step (2), and reacting at 40-60 DEG C for 24-72 hours, so as to obtain hydrolysate containing reducing sugar. According to the method provided by the invention, a method for promoting the enzymolysis of cellulose by virtue of 1,2-propylene glycol and an ionic liquid type cationic surfactant, namely 1-hexadecyl chloropyridine salt is disclosed for the first time, the content of reducing sugar is high, the production process is simple, and the environmental pollution is avoided; and the method is a safe production process beneficial to the improvement of the enzymolysis effect of cellulose.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Preparation method of citral Pickering emulsion stabilized with modified corn starch

ActiveCN108741002AReduce the degradation rateReduce degradationFood scienceFreeze-dryingPickering emulsion

The invention provides a preparation method of citral Pickering emulsion stabilized with modified corn starch. The corn starch sold in the market is used as a raw material, and through esterificationand modification of octenyl succinic anhydride and freeze drying, the modified corn starch is obtained; and modified corn starch powder dissolves in a citric acid-sodium citrate acid buffer solution of which the pH is 3, under high-speed homogenizing, citral and medium-chain triglyceride are added, and the citral Pickering emulsion is prepared. The citral Pickering emulsion prepared by the preparation method disclosed by the invention is simple and mild in preparation condition, has the characteristics of being natural, environmentally-friendly and the like in raw materials, and good in stability, and the degradation of the citral under acid condition can be effectively relieved.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com