Preparation method of citral Pickering emulsion stabilized with modified corn starch

A Pickering emulsion and corn starch technology, applied in the field of food chemical industry, can solve the problems of poor stability, easy degradation and deterioration of citral, and achieve the effects of good stability, natural raw materials and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

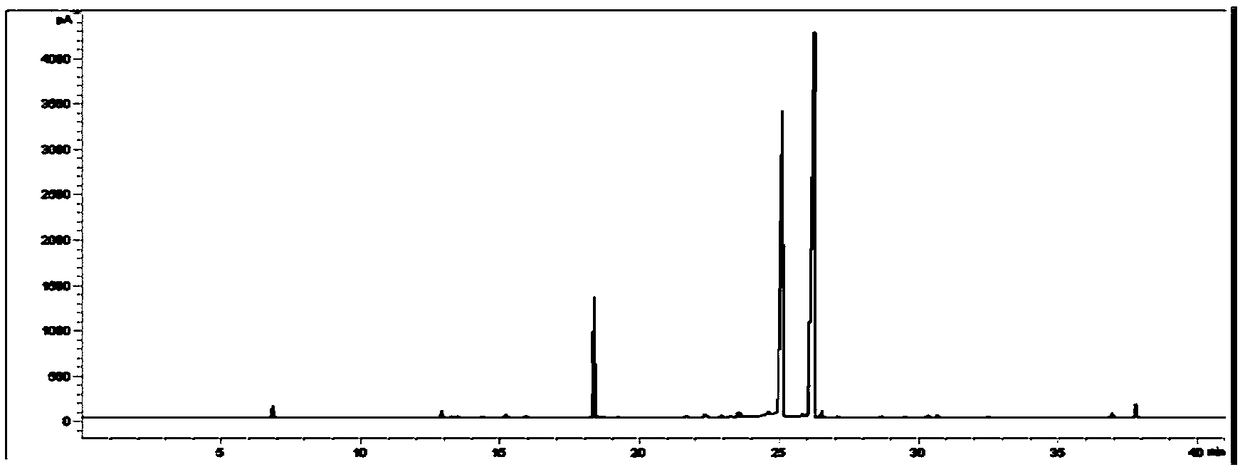

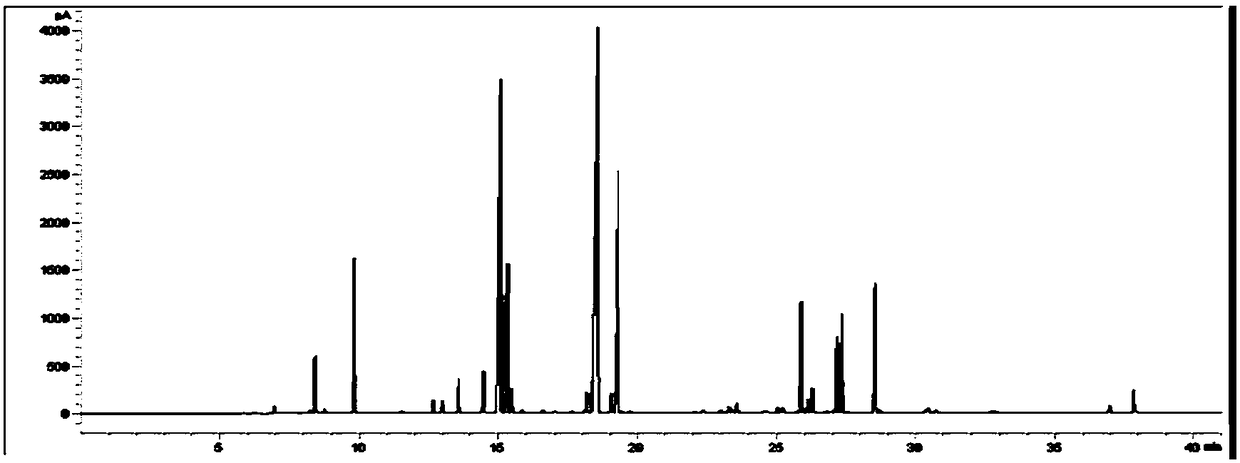

Image

Examples

Embodiment 1

[0025] 1) Preparation of cornstarch milk

[0026] Dissolve cornstarch in 100mL deionized water, stir until fully dissolved to form starch milk with a mass volume concentration of 35%, adjust the pH of the starch milk to 8.2 with 1mol / L NaOH solution, and place the starch milk in a constant temperature water bath at 36°C Internal magnetic stirring heating, the magnetic stirring speed is 500r / min.

[0027] 2) Modification of corn starch

[0028] Add 1.5% (w / w, based on starch dry base) octenyl succinic anhydride dropwise to the starch milk in step 1), and the time is controlled within 2 hours. During the reaction, 1mol / L NaOH solution is continuously added dropwise to control the concentration of the system. The pH value was kept constant at 8.2 to ensure the progress of the esterification reaction. After 5 hours of reaction, the pH of the system was adjusted to 6.5 with 1 mol / L dilute hydrochloric acid to terminate the esterification reaction.

[0029] 3) Preparation of modif...

Embodiment 2

[0035] 1) Preparation of cornstarch milk

[0036]Dissolve cornstarch in 100mL deionized water, stir until fully dissolved to form starch milk with a mass volume concentration of 40%, adjust the pH of the starch milk to 8.0 with 1mol / L NaOH solution, and place the starch milk in a constant temperature water bath at 40°C Internal magnetic stirring heating, the magnetic stirring speed is 400r / min.

[0037] 2) Modification of corn starch

[0038] Add 2% (w / w, based on starch dry base) octenyl succinic anhydride dropwise to the starch milk in step 1), the time is controlled within 2.5h, and 1mol / L NaOH solution is continuously added dropwise during the reaction to control the system The pH value of the solution was kept constant at 8.0 to ensure the progress of the esterification reaction. After reacting for 5 hours, the pH of the system was adjusted to 6.5 with 1mol / L dilute hydrochloric acid to terminate the esterification reaction.

[0039] 3) Preparation of modified corn star...

Embodiment 3

[0045] 1) Preparation of cornstarch milk

[0046] Dissolve cornstarch in 100mL deionized water, stir until fully dissolved to form starch milk with a mass volume concentration of 28%, adjust the pH of the starch milk to 8.5 with 1mol / L NaOH solution, and place the starch milk in a constant temperature water bath at 33°C Internal magnetic stirring heating, the magnetic stirring speed is 600r / min.

[0047] 2) Modification of corn starch

[0048] Add 3% (w / w, based on starch dry base) octenyl succinic anhydride dropwise to the starch milk in step 1), and the time is controlled within 3.5h, and 1mol / L NaOH solution is continuously added dropwise during the reaction to control the system The pH value of the solution was kept constant at 8.5 to ensure the progress of the esterification reaction. After reacting for 5 hours, the pH of the system was adjusted to 6.5 with 1mol / L dilute hydrochloric acid to terminate the esterification reaction.

[0049] 3) Preparation of modified corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com