Method for preparing guar gum oligogalactomannan enzymolysis solution by composite enzyme process

A technology of mannose enzymatic hydrolysis solution and compound enzymatic method, which is applied in the field of preparing guar gum oligogalactomannose enzymatic hydrolysis solution, can solve the problems of long time, low enzymatic hydrolysis efficiency, low oligosaccharide and the like, and saves energy Production time and cost, no toxic side effects, good enzymatic hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

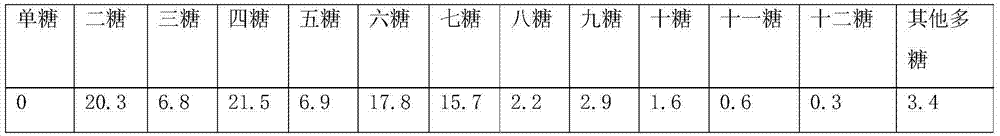

[0027] Mix 8 g of guar gum powder with 400 U of β-mannanase, 8000 U of endoglucanase, and 8000 U of cellobiase; The pH value is 6.0; the solution is heated to 22°C and swells for 30 minutes. Then the temperature of the solution was raised to 50° C., and the enzymatic hydrolysis was carried out for 6 hours; after the end of the enzymatic hydrolysis, an enzymatic hydrolysis solution of oligogalactomannose was obtained. The mass percentages of galactomannose oligosaccharides with different degrees of polymerization in the enzymatic hydrolysis solution of this example measured by MALDI-TOF and HPLC methods are shown in Table 1. 95.7% of the composition.

[0028] Table 1 The mass percent of galactomannose with different degrees of polymerization in Example 1

[0029]

Embodiment 2

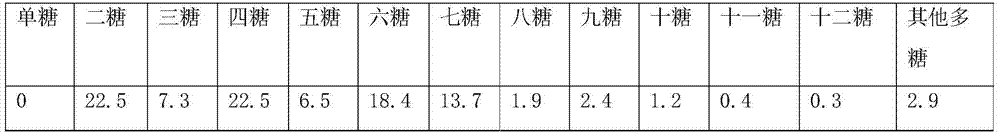

[0031] Mix 10 g of guar gum powder with 600 U of β-mannanase, 20,000 U of endoglucanase, and 15,000 U of cellobiase; The pH value is 6.3; the temperature of the solution is raised to 26°C, and it is swelled for 60 minutes; then the temperature of the solution is raised to 52.5°C, and the enzymolysis is performed for 8 hours; The mass percentages of galactomannose oligosaccharides with different degrees of polymerization in the enzymatic hydrolyzate of this example measured by MALDI-TOF and HPLC methods are shown in Table 2, and galactomannose oligosaccharides with a degree of polymerization of 2-10 account for the sugars in the enzymatic hydrolyzate 96.4% of the composition.

[0032] Table 2 The mass percent of galactomannose with different degrees of polymerization in Example 2

[0033]

Embodiment 3

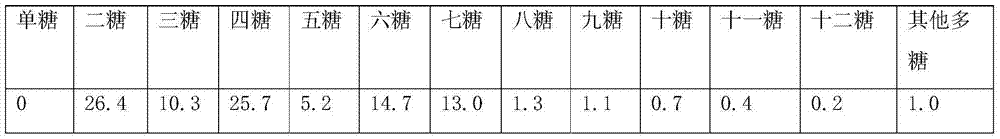

[0035] 12g of guar gum powder was fully mixed with 840U of β-mannanase, 36000U of endoglucanase and 24000U of cellobiase; The pH value is 6.6; the solution is warmed up to 30°C and swells for 90min. Then the temperature of the solution was raised to 55° C., and the enzymatic hydrolysis was carried out for 10 hours; after the end of the enzymatic hydrolysis, an enzymatic hydrolysis solution of oligogalactomannose was obtained. The mass percentages of galactomannose oligosaccharides with different degrees of polymerization in the enzymatic hydrolysis solution of this example measured by MALDI-TOF and HPLC methods are shown in Table 3, and galactomannose oligosaccharides with a degree of polymerization of 2-10 account for the sugars in the enzymatic hydrolysis solution 98.4% of ingredients.

[0036] Table 3 The mass percent of galactomannose with different degrees of polymerization in Example 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com