Method for preparing peptone from enzymatically-hydrolyzed earthworm dry powder and purpose of peptone

A technology for preparing peptone and earthworm powder, which is applied in bacteria, fermentation and other directions, can solve the problem of not finding protein by enzymatic hydrolysis of earthworm powder, and achieve the effects of rich amino acid species, good effect and high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

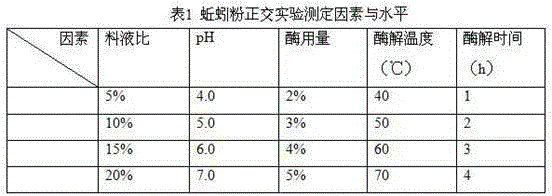

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of peptone prepared by enzymatic hydrolysis of earthworm powder:

[0019] Degreasing of earthworm powder: take earthworm powder, pre-dry in a dryer at room temperature for 10-15 minutes, use Soxhlet extraction system, and extract with petroleum ether for 25-30 minutes at 45°C-55°C. The liquid ratio is earthworm powder: petroleum ether = 1g: 5~10ml, rinse with petroleum ether for 25~30min, and after degreasing, place the sample in a fume hood to fully evaporate to dry to obtain degreased earthworm powder.

[0020] Fully wash fresh earthworms with clean water to remove surface impurities, soak them in 0.1% salt water for 15-20 minutes, and wash them with clean water after soaking. Pour the washed fresh worms into boiling water at 90°C~100°C for 1~2min. After the completion, remove the filtered water, put them in an oven, and dry them at 80°C~100°C for 6~8 hours to obtain dried earthworms. Earthworm powder was crushed with a pulverizer, and its wate...

Embodiment 2

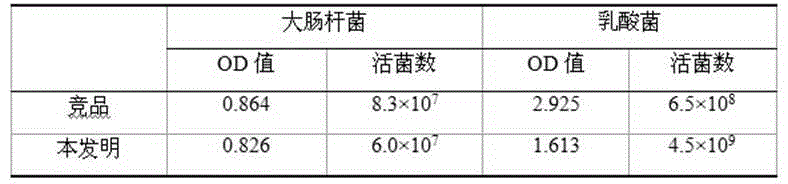

[0025] Experiments on cultivating Escherichia coli and lactic acid bacteria with earthworm peptone:

[0026] Competitor (LB medium) content (g / 100ml) Content of medium prepared by earthworm peptone of the present invention (g / 100ml) Peptone 1.0 - Peptone of the present invention - 1.0 Yeast extract 0.5 0.5 NaCl 1.0 1.0

[0027] Competitor (MRS medium) content g / 100ml) Content of medium prepared by earthworm peptone of the present invention (g / 100ml) casein peptone 1.0 - Homemade Peptone - 1.0 Beef Extract 1.0 1.0 yeast extract 0.5 0.5 glucose 0.5 0.5 sodium acetate 0.5 0.5 Diammonium citrate 0.2 0.2 Tween 80 0.1 0.1 Dipotassium phosphate 0.2 0.2 Magnesium Sulfate Heptahydrate 0.02 0.02 Manganese Sulfate Heptahydrate 0.005 0.005

[0028] Note: "-" means no such substance

[0029] The comparison of the OD value and viable count results bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com